An auxiliary device for unloading foundry sand after the casting is formed

A technology for casting molding and foundry sand is applied in the field of auxiliary devices for unloading foundry sand, which can solve problems such as affecting casting efficiency, slow efficiency, and easy doping of impurities, so as to ensure the use effect of casting, prolong the service life, and reduce the friction coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

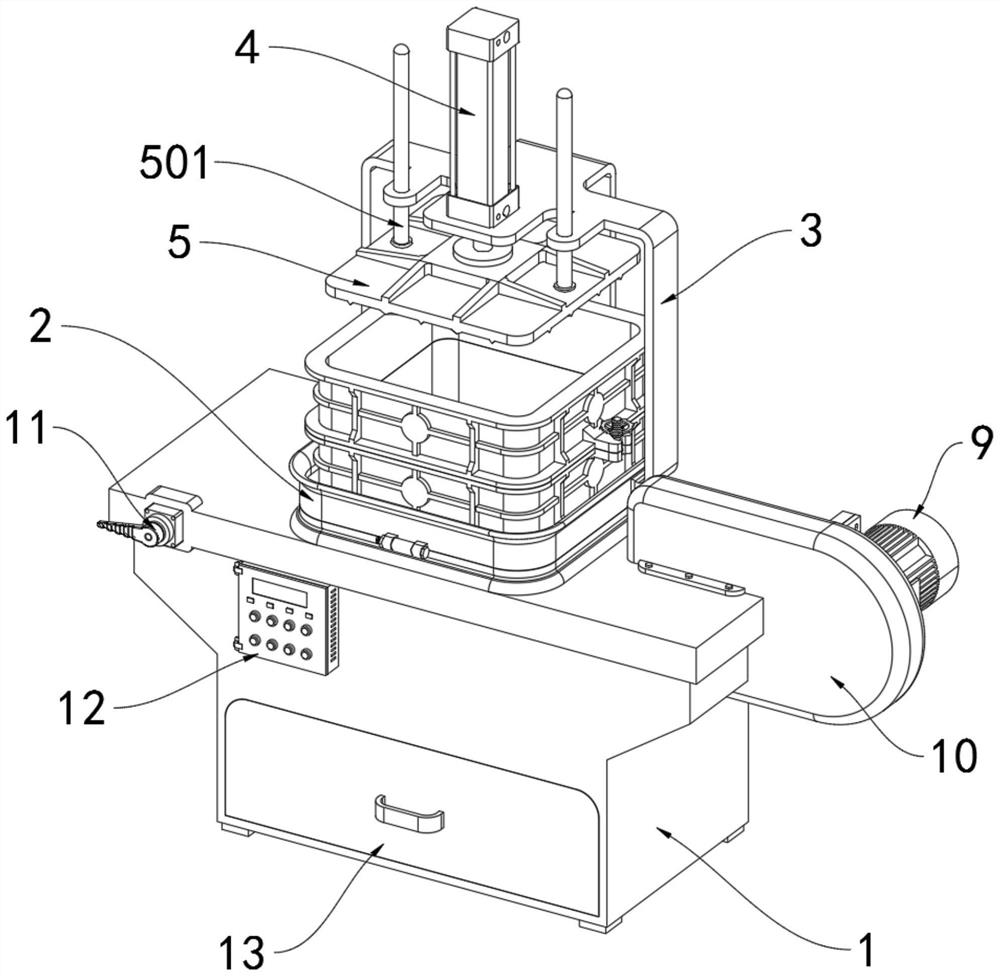

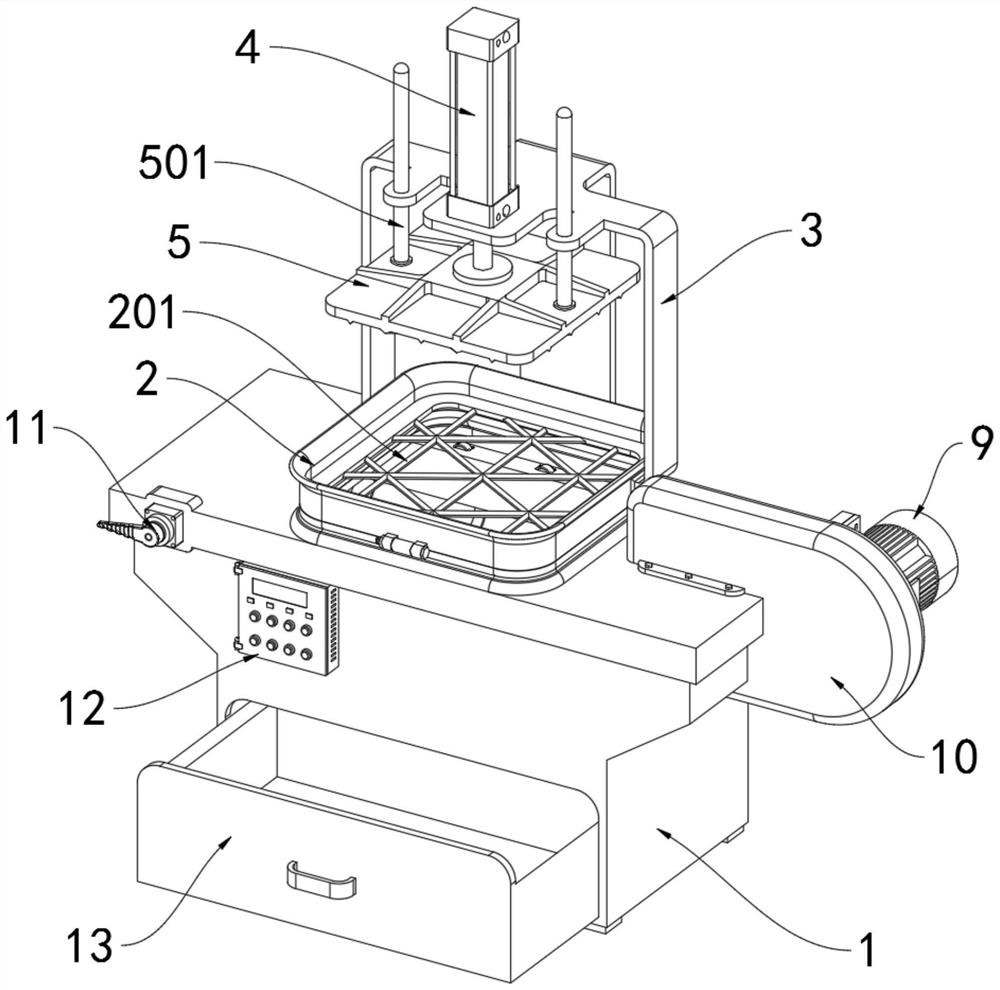

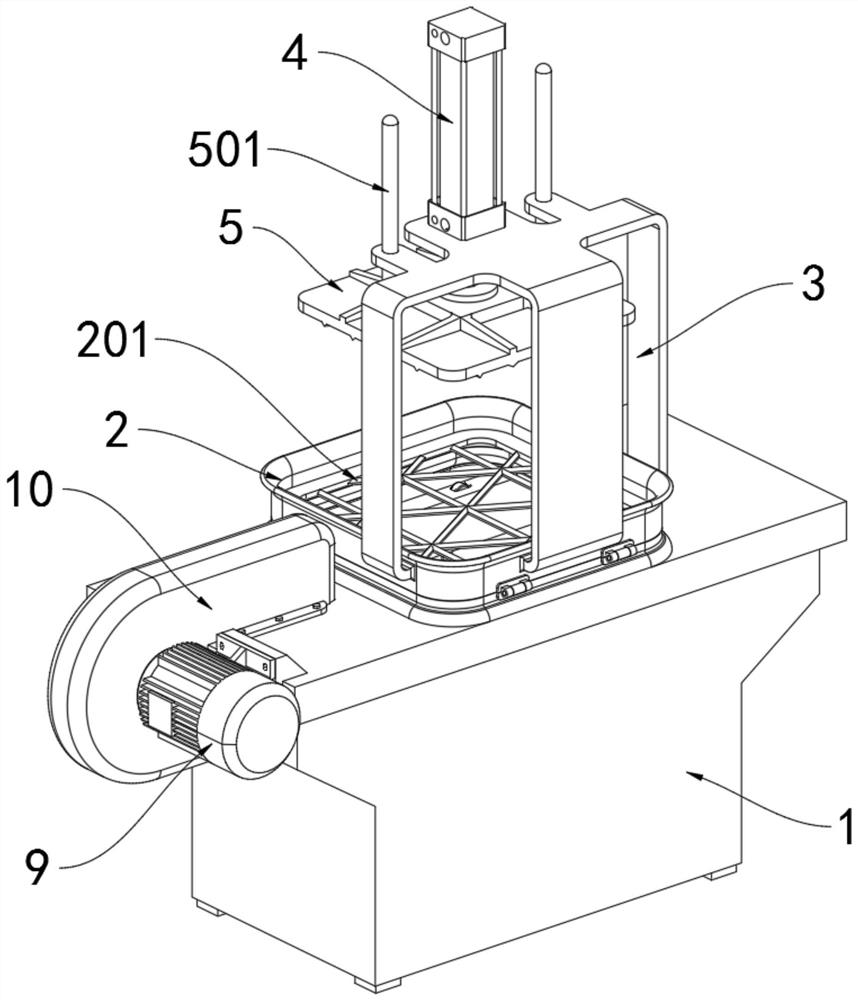

[0032] Append figure 1 Adherent Figure 10 Down:

[0033]The present invention provides a cast sand-shaping auxiliary device after casting member, including auxiliary table 1, a receiving frame 2, a support frame 3, a cylinder 4, a pressure plate 5, a screen surface 6, a motor 9, and a sealing cover 10; The auxiliary table 1 is a hollow structure, and a square into the top of the auxiliary table 1 has a square intosert 101; one side of the inner wall of the auxiliary table 1 has a slide groove 102, and the sand drawing drawer 13 slides to place The auxiliary table 1 is located at the bottom of the auxiliary table 1, and the support frame 3 is mounted at the top of the support frame 2; the cylinder 4 manually controls the valve 11 through the trachea and the auxiliary table 1, and manually The control valve 11 is in communication with the external air supply line; the pressure plate 5 is a square plate structure, and the pressure plate 5 is located directly above the receiving frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com