Intelligent planer for wood processing

A planer, intelligent technology, applied in wood processing appliances, processing machines for manufacturing flat surfaces, manufacturing tools, etc., can solve problems such as waste of resources, trouble in cleaning wood chips, and reduction of automatic intelligence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

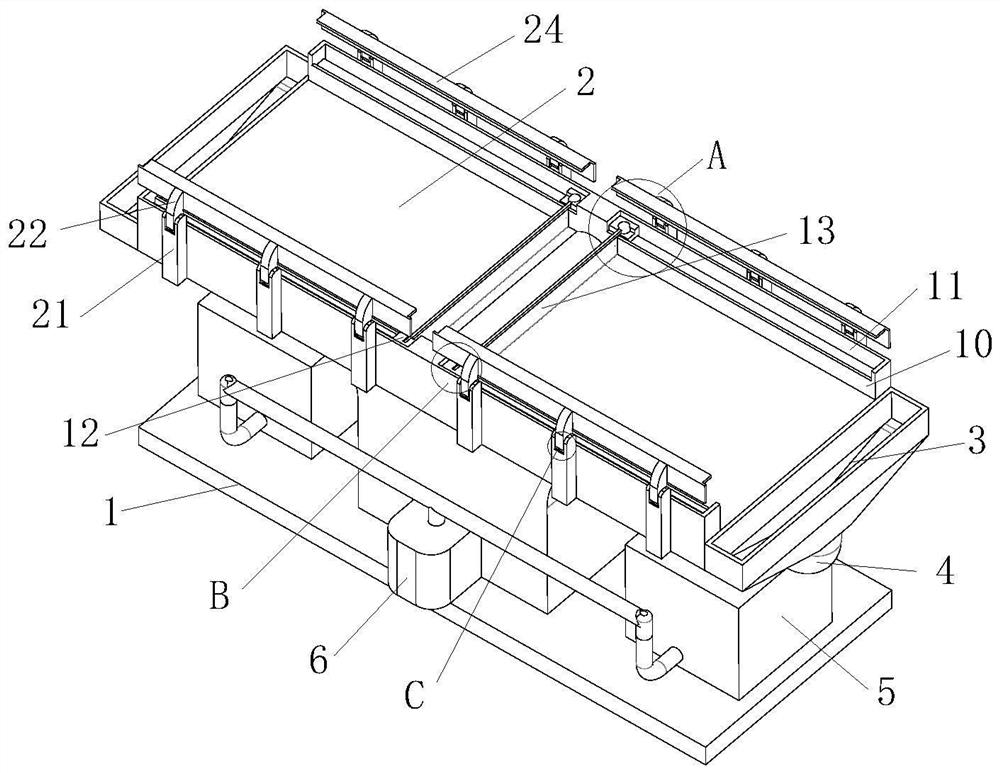

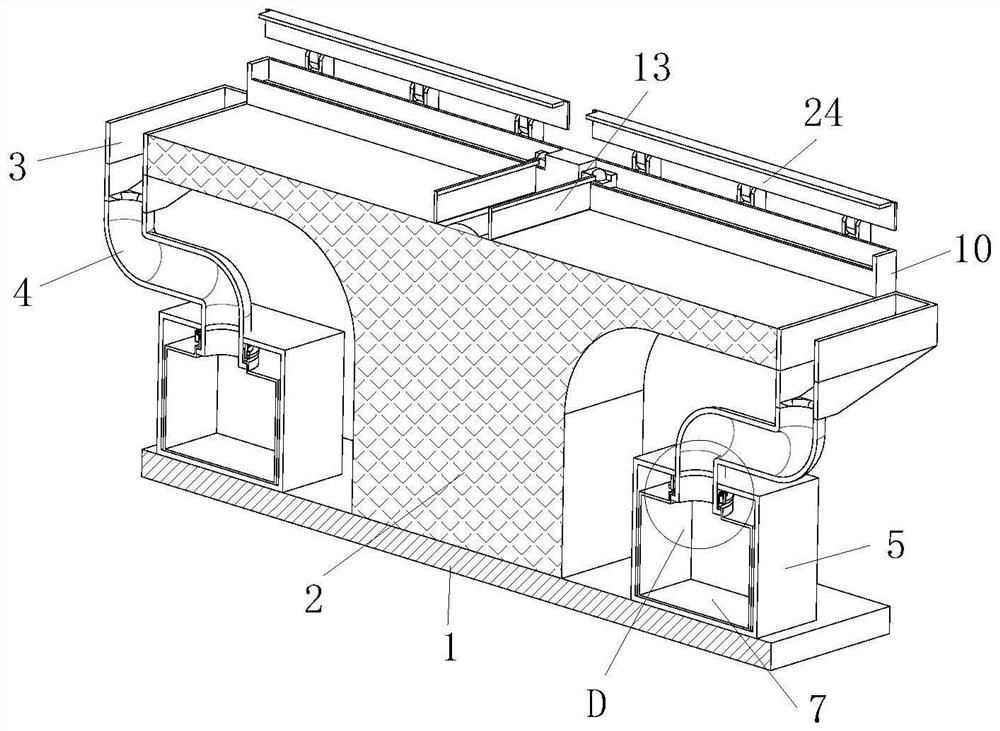

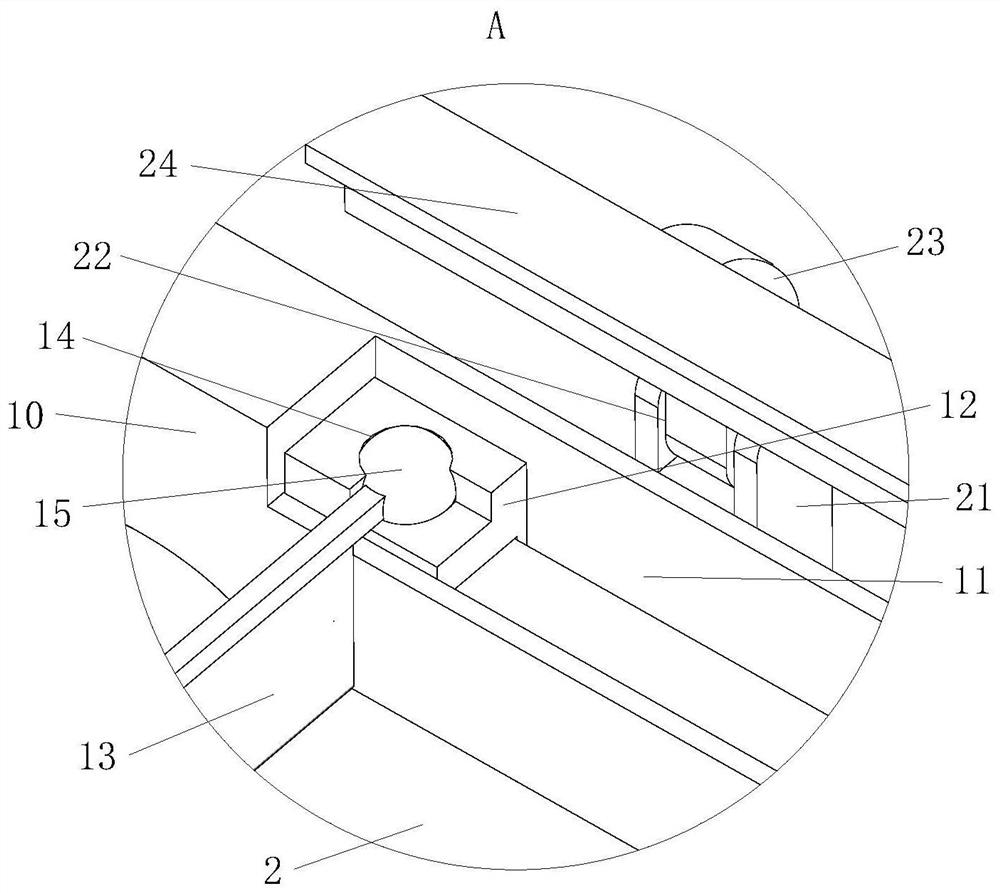

[0031] Such as Figure 1 to Figure 7 As shown, an intelligent planer for wood processing according to the present invention includes a base 1, a planer body 2 and a collection assembly; The collection components are installed on both the end and bottom surfaces;

[0032] The collection assembly includes a collection funnel 3, a collection pipe 4, a collection box 5 and an air extractor 6; both ends of the top surface of the base 1 are fixed to the collection box 5, and the front of the planer body 2 is affixed with an air extractor 6. The air inlet pipe of the air extractor 6 is connected to the collection box 5, the two ends of the planer body 2 are fixed to the collection funnel 3, the bottom surface of the collection funnel 3 is fixed to the collection pipe 4, and the collection pipe 4 The bottom of the bottom is connected to the top surface of the collection box 5; when working, the staff will sweep the wood chips on the surface of the planer body 2 into the collection bo...

Embodiment 2

[0041] Such as Figure 8 to Figure 9 As shown, the bottom surface of the push plate 13 is provided with a plurality of round holes 30, and the middle part of the round holes 30 is provided with a ring groove 31, and the inside of the round holes 30 is slidably installed with a slide bar 32, and the middle part of the slide bar 32 is fixed. Connect the circular plate 33, the outer ring of the circular plate 33 is slidingly matched with the inner ring of the ring groove 31, the top surface of the circular plate 33 is fixedly connected with the second spring 34, and the top of the second spring 34 is in contact with the ring groove 31 The top surface of the second spring 34 is affixed to the top surface, the inner ring of the second spring 34 is covered with the outer ring of the slide bar 32, the bottom end of the slide bar 32 is fixedly connected to the brush 35, and the middle part of the bottom surface of the chute 11 is provided with a receiving groove 36, The inner wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com