Form-following adjusting base plate of large-size thin-wall structure part for selective laser melting forming

A technology of laser selective melting and thin-walled structural parts, which is applied in the direction of improvement of process efficiency, additive manufacturing, additive processing, etc., can solve problems such as large welding deformation and difficult production of test pieces, and achieve good forming quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

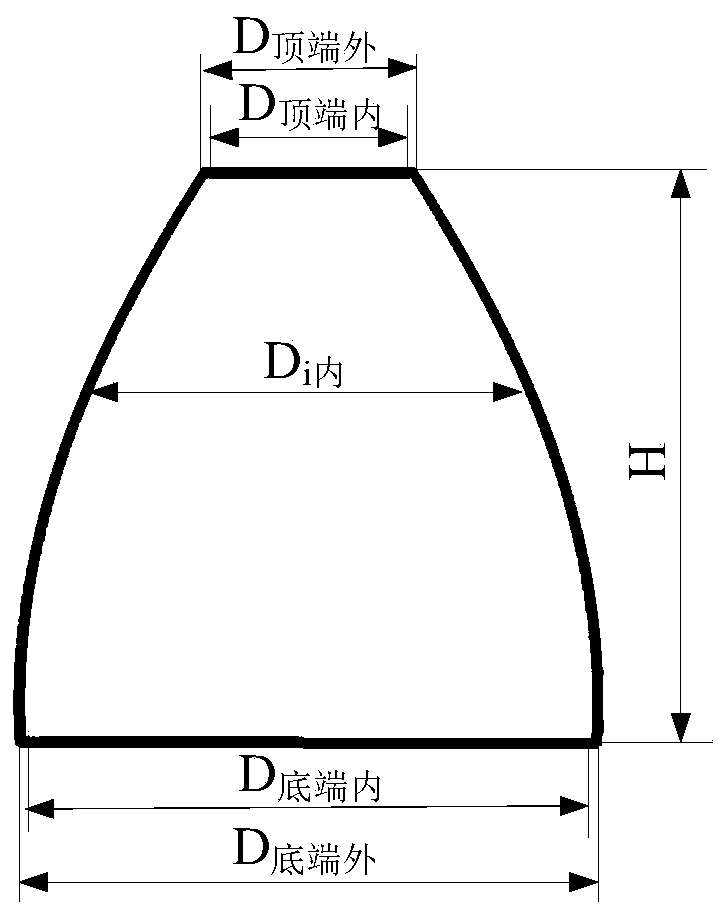

[0014] Such as Figure 1-3 As shown, taking the large-scale superalloy thin-walled structural parts as an example, the top outer diameter D 顶端外 : 262mm, inner diameter D 顶端内 : 250mm, bottom outer diameter D 底端外 : 1158mm, inner diameter D 底端内 : 1146mm, structural part height H: 1000mm.

[0015] (1) Selection of substrate material: large-scale thin-walled structural parts are made of superalloy materials, and the material of the substrate is No. 45 steel;

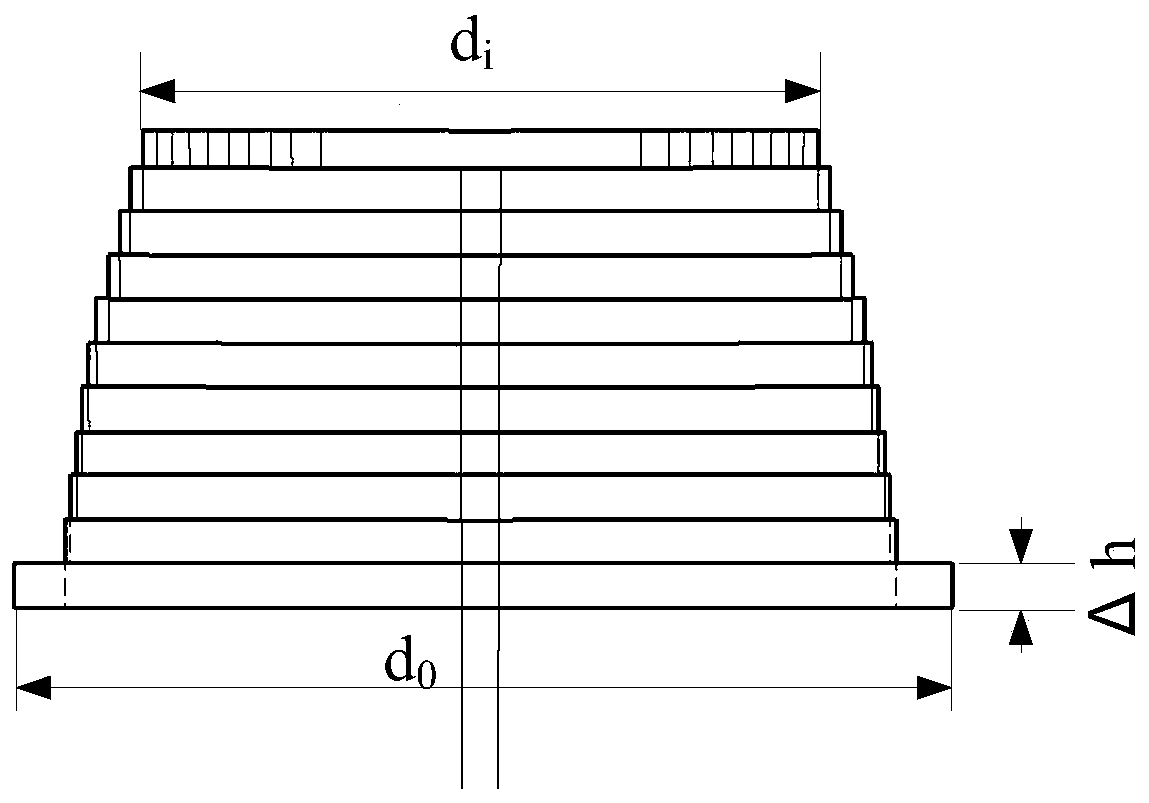

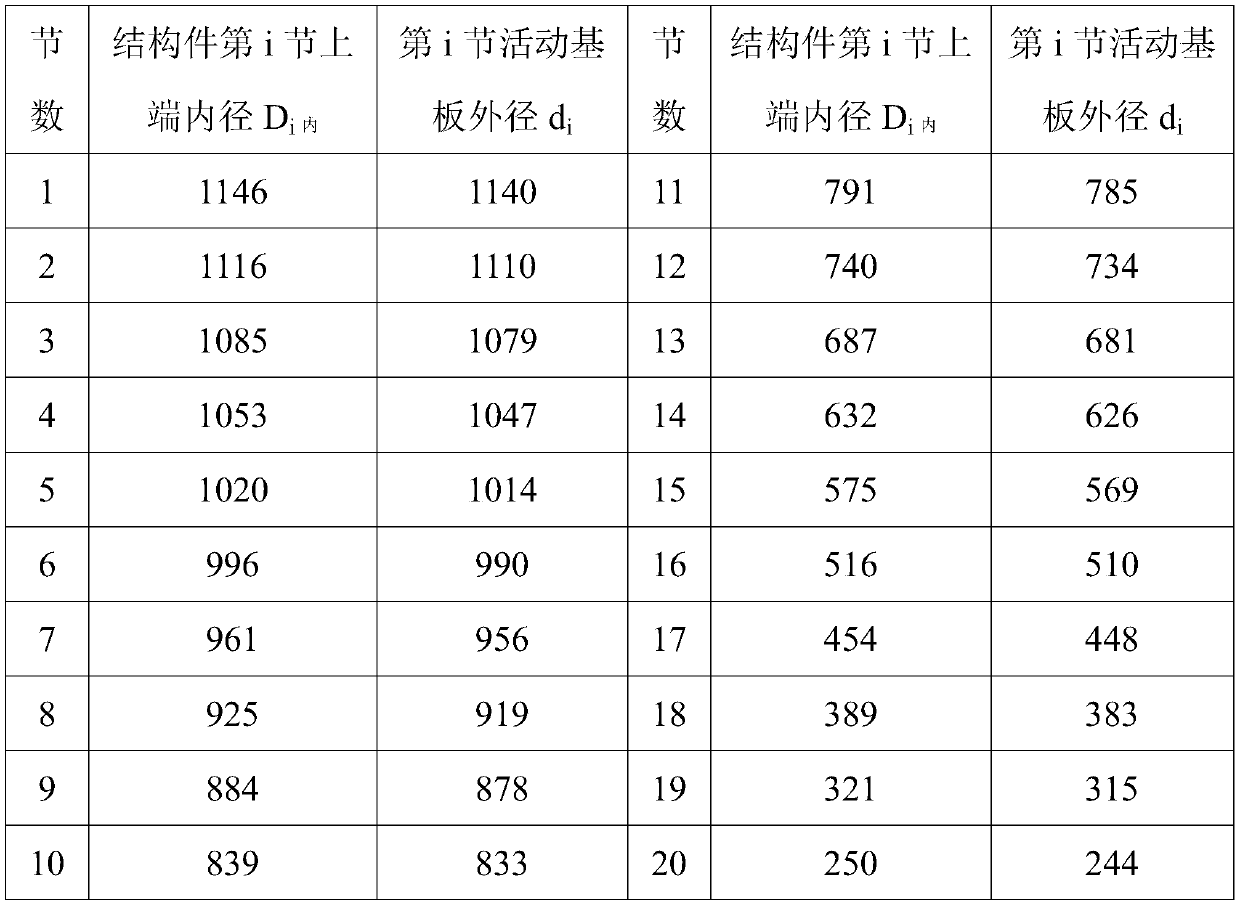

[0016] (2) Determination of substrate size: the number n of movable substrate sections is taken as 20, and the thickness of each movable substrate Δh=H / n=1000mm / 20=50mm is determined by the outer diameter of the bottom of the large-format superalloy thin-walled structural part D. 底端外 Determine the outer diameter d of the outermost ring of the circular substrate 0 =D 底端外 +40mm=1158mm+40mm=1198mm, the outer diameter of the first to 20th movable base plate is according to the formula d i =D i内 -6mm for calculation, see ...

example 2

[0020] Example 2: Taking large-format titanium alloy thin-walled structural parts as an example, the top outer diameter D top outside: 314mm, the inner diameter D top inside: 300mm, the bottom outer diameter D bottom outside: 1448mm, and the inner diameter D bottom inside: 1434mm , Structure height H: 1200mm.

[0021] (1) Selection of substrate material: large-format thin-walled structural parts are titanium alloy materials, and the substrate material is the same grade of titanium alloy;

[0022] (2) Determination of substrate size: the number n of movable substrate sections is taken as 30, the thickness of each movable substrate Δh=H / n=1200mm / 30=40mm, and the outer diameter of the bottom end of the large-format titanium alloy thin-walled structural part The outer diameter of the outermost ring of the circular substrate is determined outside the bottom of D = d0 = outside the bottom of D + 40mm = 1448mm + 40mm = 1488mm, and the outer diameter of the movable substrate in Sectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap