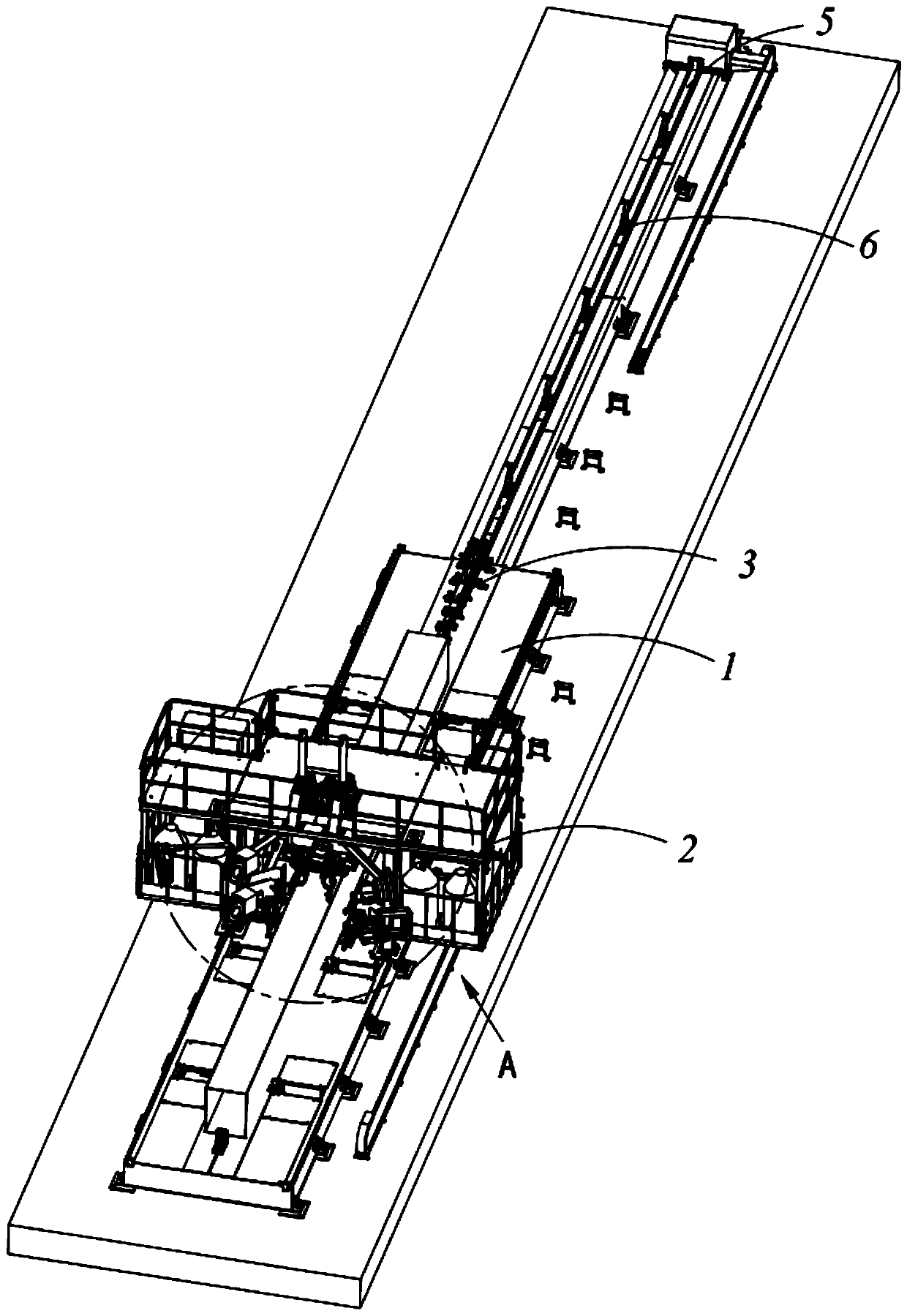

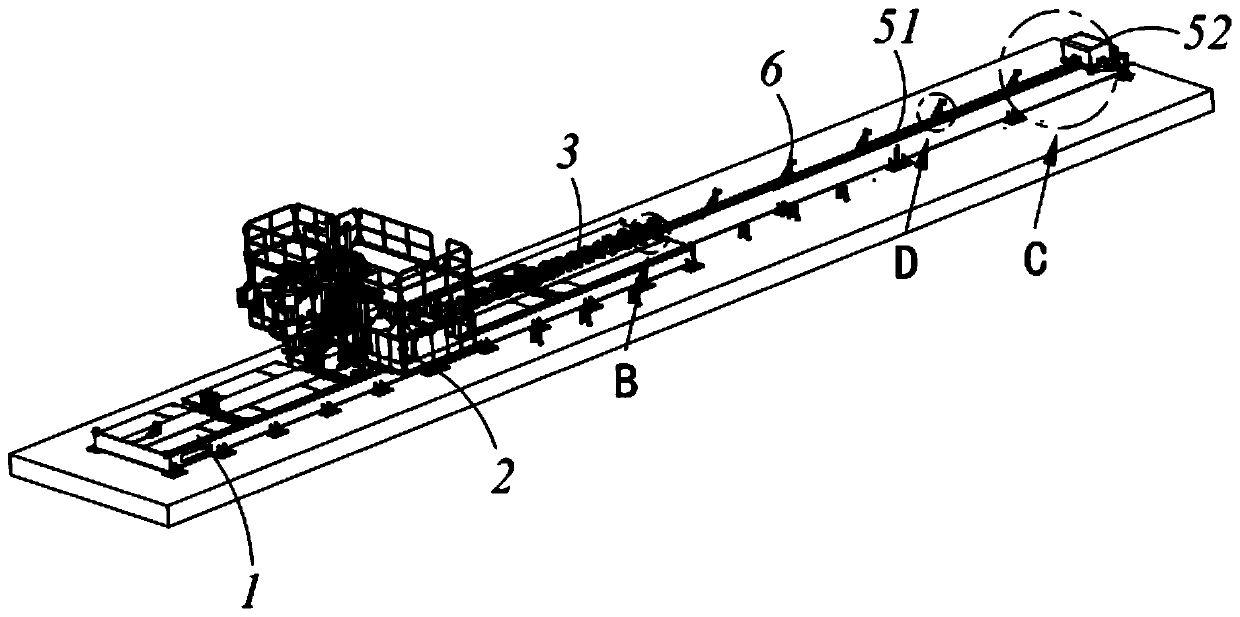

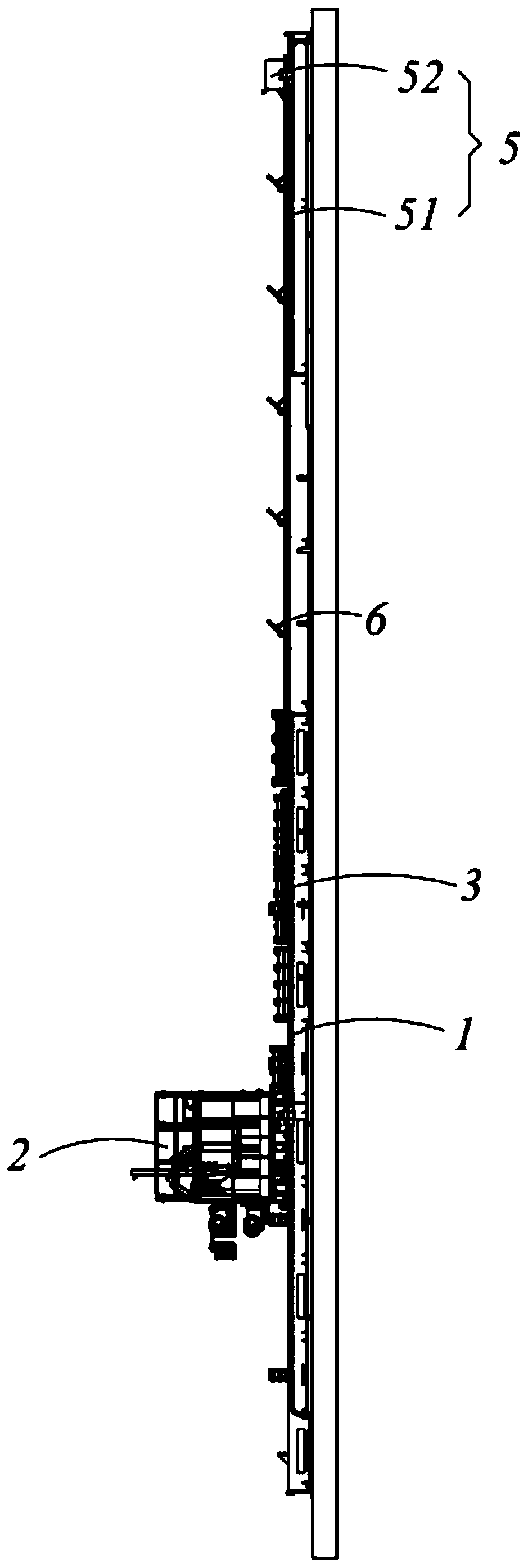

Welding system

A welding system and basic platform technology, applied in the field of cost-saving welding systems, can solve the problems of lower yield, workpiece deformation, cost increase, etc., and achieve the effect of reducing production cost and length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0052] Such as Figure 9 As shown, the inner support tool 3 includes an inner support member 31 and a rolling wheel 32 arranged around the inner support member 31. In this embodiment, the inner support member 31 is a rectangular tubular structure, and the rolling wheel 32 They are respectively disposed on the upper side wall 832 and the two side walls 832 in the width direction of the inner support member 31 . The inner support 31 of the present invention also provides another embodiment, the inner support 31 includes an upper inner support 31 and a lower inner support 31 arranged at intervals up and down, and the upper inner support 31 and the lower inner support 31 A plurality of supporting parts 33 arranged at intervals along the length direction are arranged between the inner braces 31, which can greatly reduce the cost of the inner braces 31. Of course, in other embodiments, the inner braces can also be other shape.

[0053] Such as Figure 10 to Figure 15 As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com