Tool handle scrap entrainment detection device calibrator

A technology of detection device and calibrator, which is used in measuring/indicating equipment, metal processing mechanical parts, maintenance and safety accessories, etc., can solve the problem of chip detection device without calibration tools, etc. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

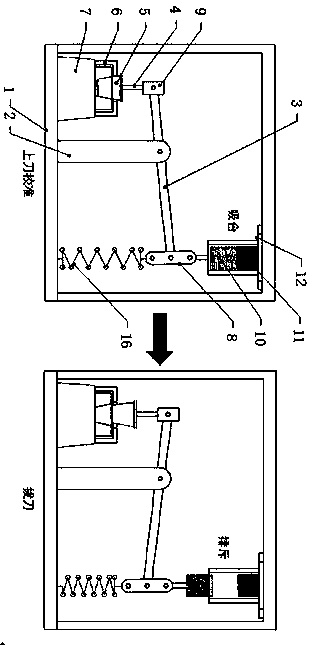

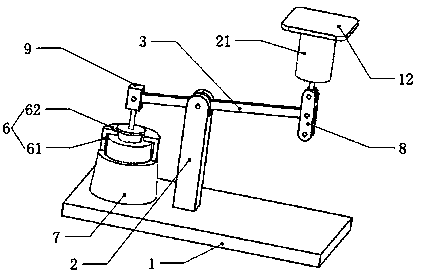

[0022] In an embodiment, a calibrator of a tool holder chip detection device includes a calibration stand 1, a support arm 2, a lever 3, a fixing frame 6, a mounting seat 7, a hinge connection block 8 of a power arm, a hinge connection block 9 of a resistance arm, and a top Moving electromagnet 10, top fixed electromagnet 11, top fixed seat 12 and spring 16.

[0023] The support arm 2 is arranged on the calibration stand 1, and its upper end is hinged with the middle part of the lever 3. The front end of the lever 3 is hinged with the resistance arm hinge block 9, and its rear end is hinged with the power arm hinge block 8.

[0024] The top fixing seat 12 is installed on the top of the calibration stand 1, which extends downwards to form a top sleeve 21, the top fixed electromagnet 11 is fixedly installed on the top of the top sleeve 21, and the top moving electromagnet 10 can be arranged on the top sleeve so that it can slide up and down. In the cylinder 21, the lower end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com