Dual purpose vehicles for unloading steel rails, capable of using on road and railway

A technology for road, railway, and dual-use vehicles, which is applied to track and road dual-use vehicles, railway car body parts, tracks, etc., can solve problems such as labor and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

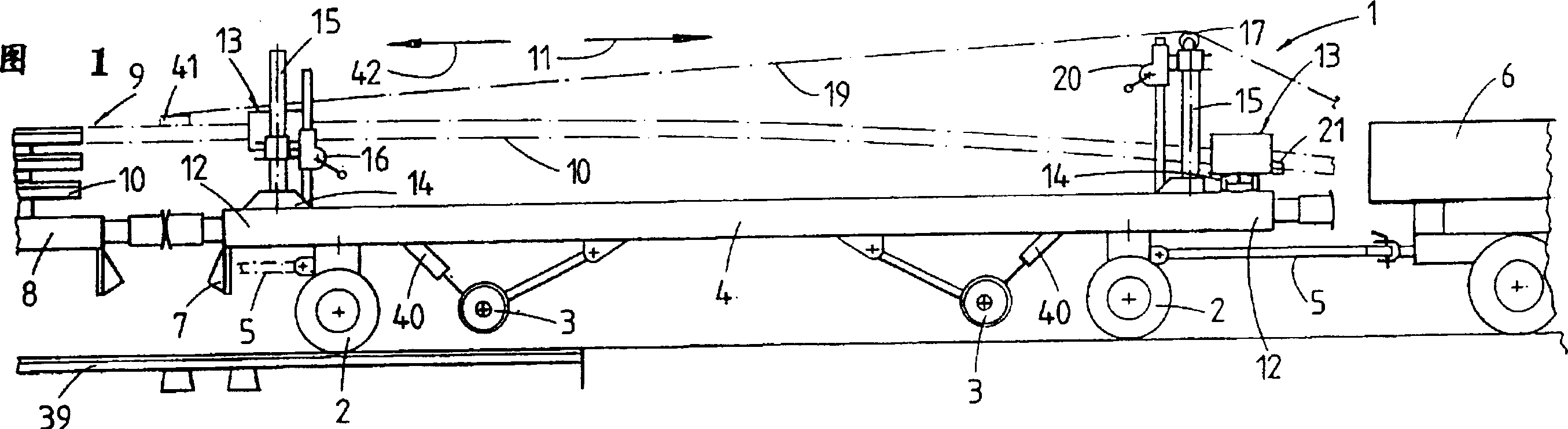

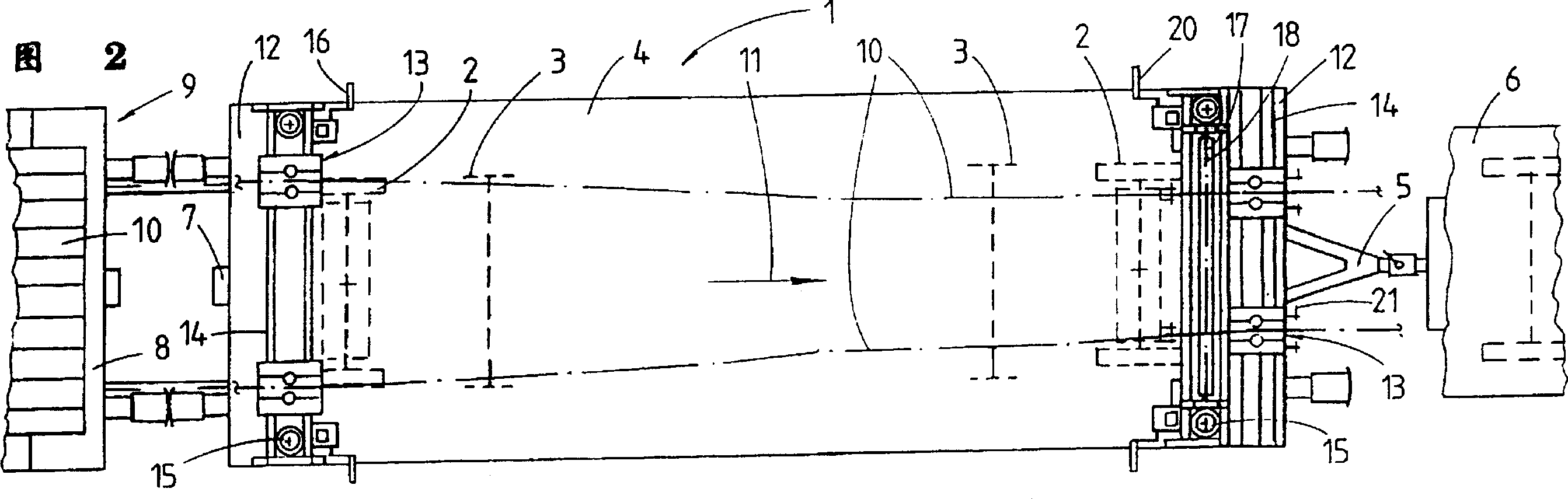

[0020] The highway and railway vehicle 1 shown in Figures 1 and 2 has an underframe 4 that can be selectively supported on the road running mechanism 2 or the rail running mechanism 3, and the underframe 4 can be connected with the road index car 6 by using the coupling device 5 stand up. The coupling device 7 that is positioned at the opposite other end is used to be connected with the delivery flat car 8 of rail (only the end of rail delivery train 9 is shown in the figure).

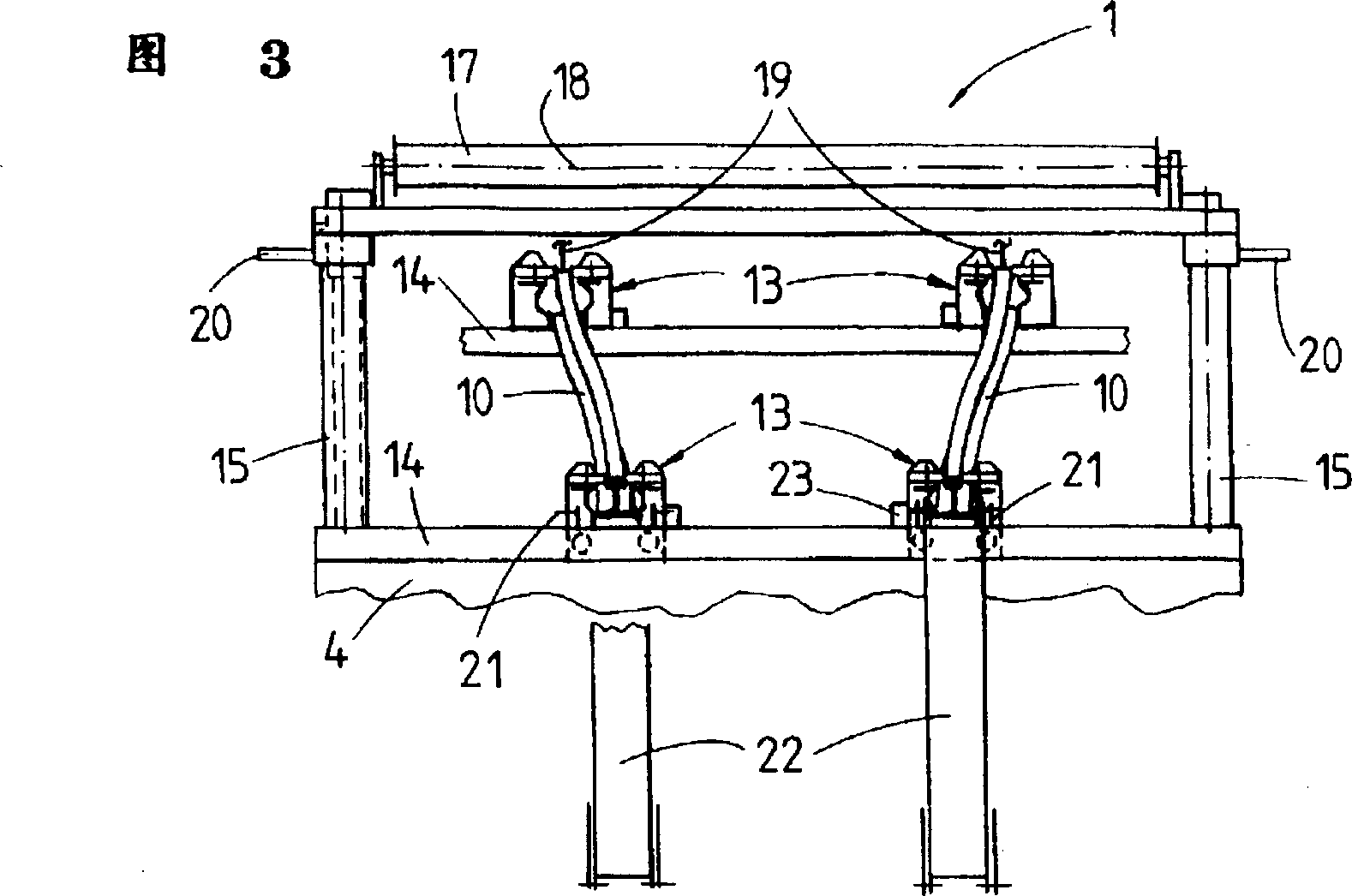

[0021] In order to remove welded elongated rails 10 from the rail transport train 9, at each end 12 (arrow 11) in the longitudinal direction of the vehicle there are two devices 13 mounted side by side in the transverse direction of the vehicle for guiding and aligning the rails to be removed. Rail 10. At each end 12 of the vehicle, the devices 13 for guiding rails arranged in pairs in the transverse direction of the vehicle can be independently moved on horizontal guide brackets 14 connected to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com