Wafer cassette placing frame and wafer storage cabinet

A wafer storage and wafer box technology, applied in the field of wafer manufacturing, can solve the problems of falling, entering the wafer box, wafer contamination, etc., to avoid pollution, prevent particle pollution, and improve cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

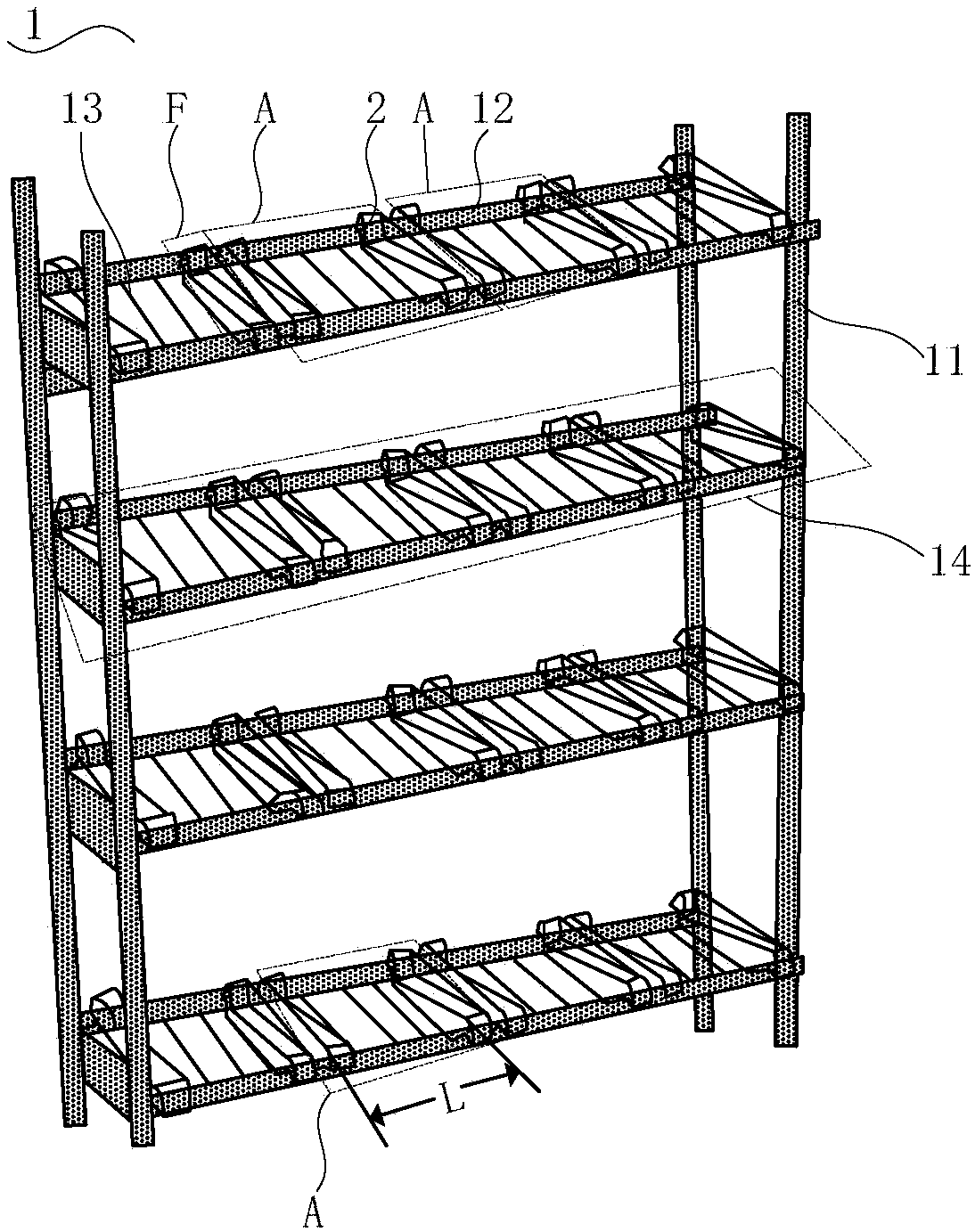

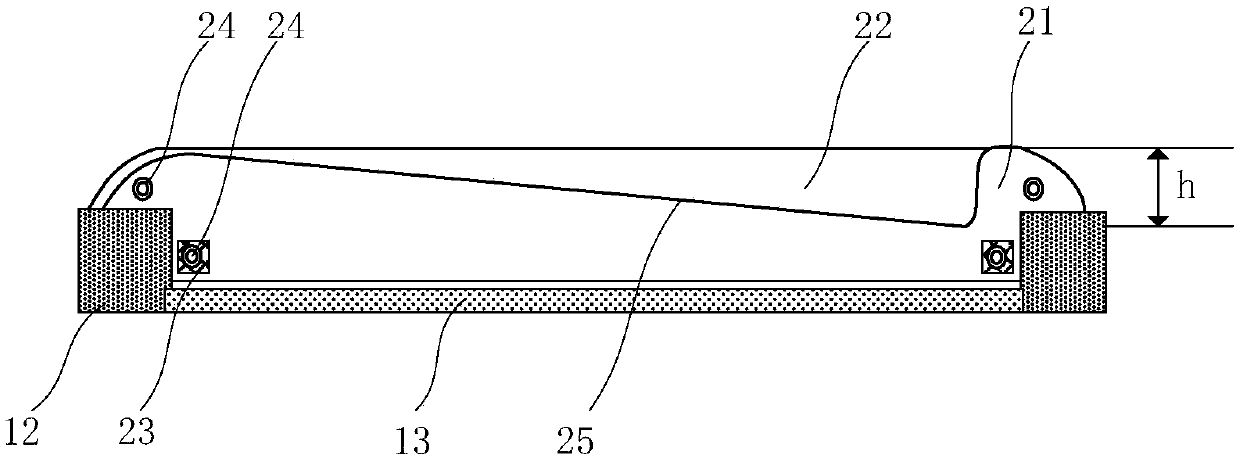

[0038] figure 1 It is a schematic structural diagram of the wafer cassette placing rack 1 according to Embodiment 1 of the present invention.

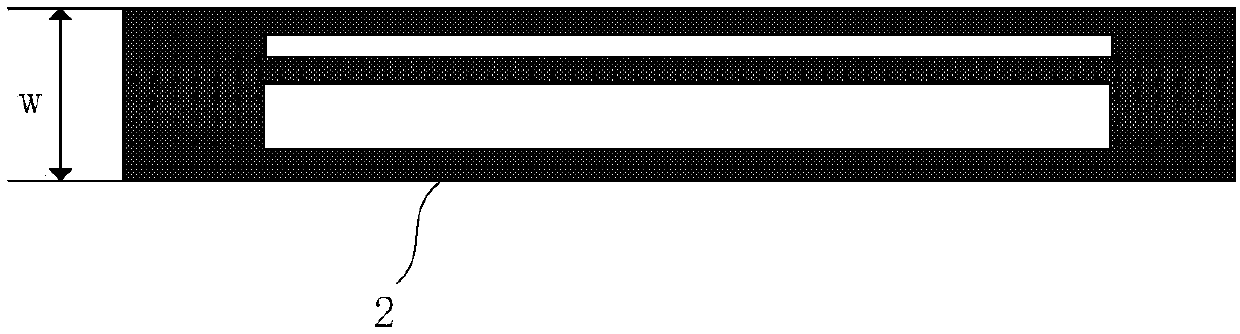

[0039] Such as figure 1 As shown, the present invention provides a wafer box placement frame 1, the wafer box placement frame 1 includes a fixed frame and an anti-friction guide rail 2 for placing a wafer box, and at least one wafer is arranged on the fixed frame Cassette placement area A; the anti-friction guide rail 2 is arranged on the wafer cassette placement area A. The wafer cassette placement rack 1 of the present invention can effectively prevent particle pollution such as stainless steel powder due to friction between the wafer cassette and the wafer cassette placement rack 1, and can effectively avoid the pollution of the wafer cassette, thereby avoiding the pollution and improve the cleanliness of the wafer.

[0040] The wafer box placement rack 1 can be in any shape, as long as it matches the specifications of the wafer ...

Embodiment 2

[0051] Figure 4 It is a schematic structural diagram of a wafer storage cabinet according to Embodiment 2 of the present invention.

[0052] Such as Figure 4 As shown, the present invention also provides a wafer storage cabinet. The wafer storage cabinet includes the wafer cassette placement rack 1 as described in Embodiment 1. For the purpose of simplicity, the wafer storage cabinet described in this embodiment The structure of the cassette rack 1 will not be described again, please refer to the first embodiment for details; the wafer storage cabinet also includes a cabinet body 3 , and the wafer cassette rack 1 is located in the cabinet body 3 .

[0053] Described cabinet body 3 can be the cabinet body of metal material, such as stainless steel material, and described cabinet body 3 can also be provided with anti-static setting, such as the anti-static belt of grounding, and described cabinet body 3 can also be provided with filtering device 4 , a dehumidification device...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific strength | aaaaa | aaaaa |

| Specific stiffness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com