Wax injection plug made of PVC waste produced during automobile manufacturing and preparation method thereof

A technology of automobile manufacturing and PVC material, applied in the field of wax injection plug and its preparation, can solve the problems of high cost and easy damage of plug

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

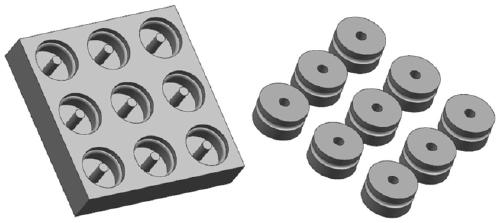

[0093] Preparation of the wax-injected plug in Example 1-1: The raw material PVC glue is the bottom material of the threshold PVC; prepare a 20wt% zinc oxide suspension, apply it evenly on the inner surface of the iron plug mold, and heat it in an oven at 120°C Dry for 2 hours to obtain a mold covered with zinc oxide layer; install the PVC glue into the mold, shake it firmly, scrape off the excess PVC glue and smooth the surface; put it in an oven at 150°C, dry for 3 hours, cool and demould to get wax injection gag.

[0094] Preparation of the wax-injected plug of Example 1-2: The raw material PVC glue is the bottom material of threshold PVC; prepare 20wt% zinc oxide suspension, apply it evenly on the inner surface of the iron plug mold, and heat it in an oven at 120°C Dry for 2 hours to obtain a mold covered with zinc oxide layer; install the PVC glue into the mold, shake it firmly, scrape off the excess PVC glue and smooth the surface; put it in an oven at 150°C, dry for 5 h...

Embodiment 2

[0108] The raw materials are the bottom of the threshold PVC (PVC glue) and the plasticizer diisononyl phthalate. Mix PVC glue and plasticizer at a mass ratio of 9:1, mechanical stirring speed is 100r / min, stir for 30min, stand still and shake alternately 3-5 times to obtain PVC-10 with evenly mixed PVC glue and plasticizer % Dinp raw material.

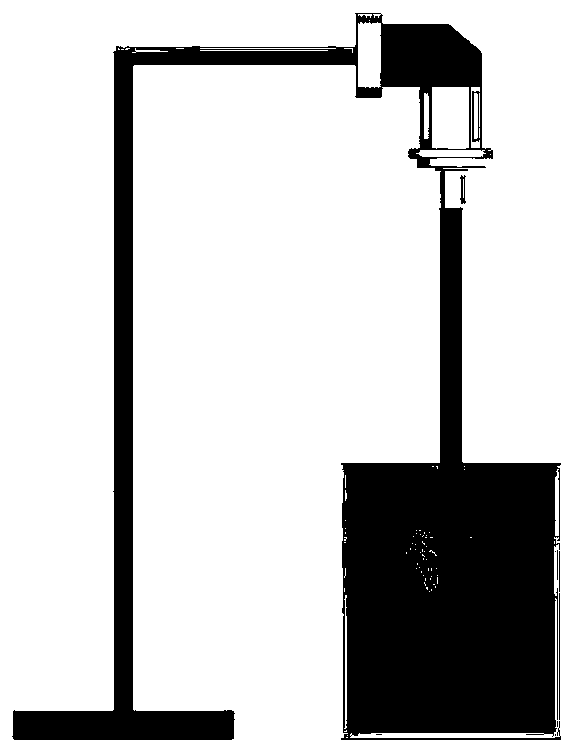

[0109] Prepare a 20% by mass zinc oxide suspension, apply it evenly on the inner surface of the iron plug mold, and dry it in an oven at 120°C for 2 hours to obtain a mold covered with a zinc oxide layer. Put the PVC-10%Dinp raw material into the mold, shake it, scrape off the excess raw material and smooth the surface. Put it in an oven at 150°C, dry for 5 hours, cool and demould to obtain a wax injection plug, which is easy to demould. Wrap the wax injection pipe and plug fixing components with tin foil, install the PVC material wax injection plug, and the plug is easy to disassemble.

Embodiment 3

[0111] The raw materials are the bottom of the threshold PVC (PVC glue) and the plasticizer diisononyl phthalate. Mix PVC glue and plasticizer at a mass ratio of 92:8, mechanically stir at a speed of 100r / min, stir for 30min, stand and shake alternately 3-5 times to obtain PVC-8 with evenly mixed PVC glue and plasticizer % plasticizer raw material.

[0112] Prepare a 20% by mass zinc oxide suspension, apply it evenly on the inner surface of the iron plug mold, and dry it in an oven at 120°C for 2 hours to obtain a mold covered with a zinc oxide layer. Put the PVC-8%Dinp raw material into the mold, shake it, scrape off the excess raw material and smooth the surface. Put it in an oven at 150°C, dry for 5 hours, cool and demould to obtain a wax injection plug, which is easy to demould. Wrap the wax injection pipe and plug fixing components with tin foil, install the PVC material wax injection plug, and the plug is easy to disassemble.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com