PC/ABS alloy material and preparation method thereof

An alloy material and alloy technology, applied in the field of PC/ABS alloy material and its preparation, can solve the problems of PC/ABS nozzle material waste, environmental pollution, etc., and achieve the goal of realizing reuse, avoiding environmental pollution problems, and reducing environmental pollution problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

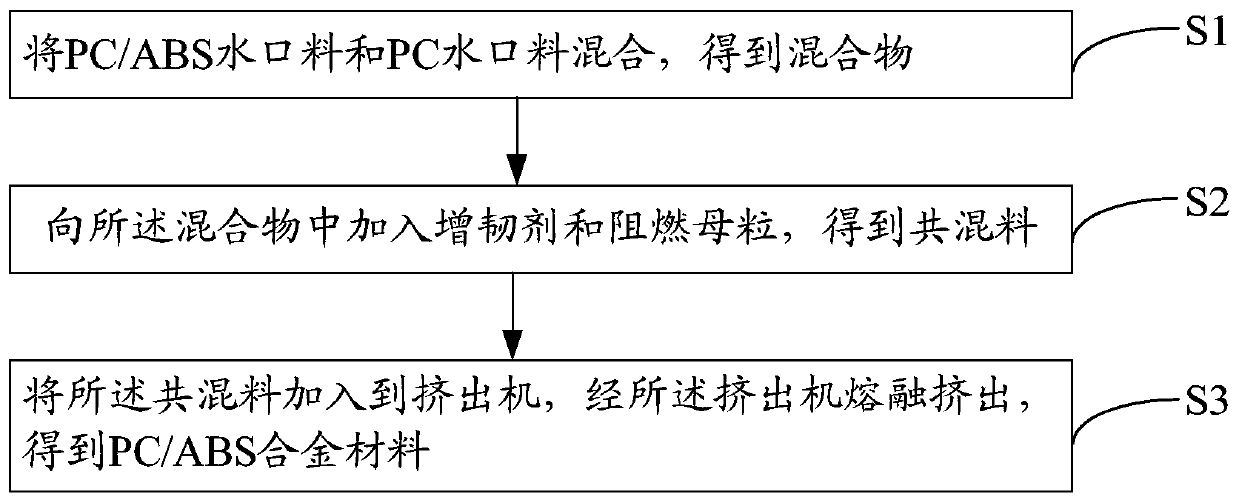

Method used

Image

Examples

Embodiment 1

[0040] Material configuration: Weigh 41 parts of PC / ABS nozzle material, 41 parts of PC nozzle material, 4 parts of MBS toughening agent, 2 parts of ABS toughening agent, 4 parts of PC flame retardant masterbatch, PC / ABS alloy flame retardant Combustion masterbatch 6.5 parts and carbon black 1.5 parts.

[0041] Preparation process: crush the PC / ABS nozzle material and PC nozzle material first, then add them to the mixer for mixing, stir and mix for 5 minutes to 10 minutes, then add MBS to the mixture of PC / ABS nozzle material and PC nozzle material for toughening Agent, ABS toughening agent, PC flame retardant masterbatch, PC / ABS alloy flame retardant masterbatch and carbon black, after mixing evenly to obtain a blend, the blend is added to the extruder, and each zone of the extruder is set The temperature is melted and extruded by an extruder to obtain a PC / ABS alloy material.

[0042] In the present invention, by blending the PC / ABS nozzle material and the PC nozzle materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com