Purification method of green prickleyash volatile oil

A purification method and volatile oil technology, which can be applied in the directions of essential oils/spice, fat production, etc., can solve the problem of low final yield and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

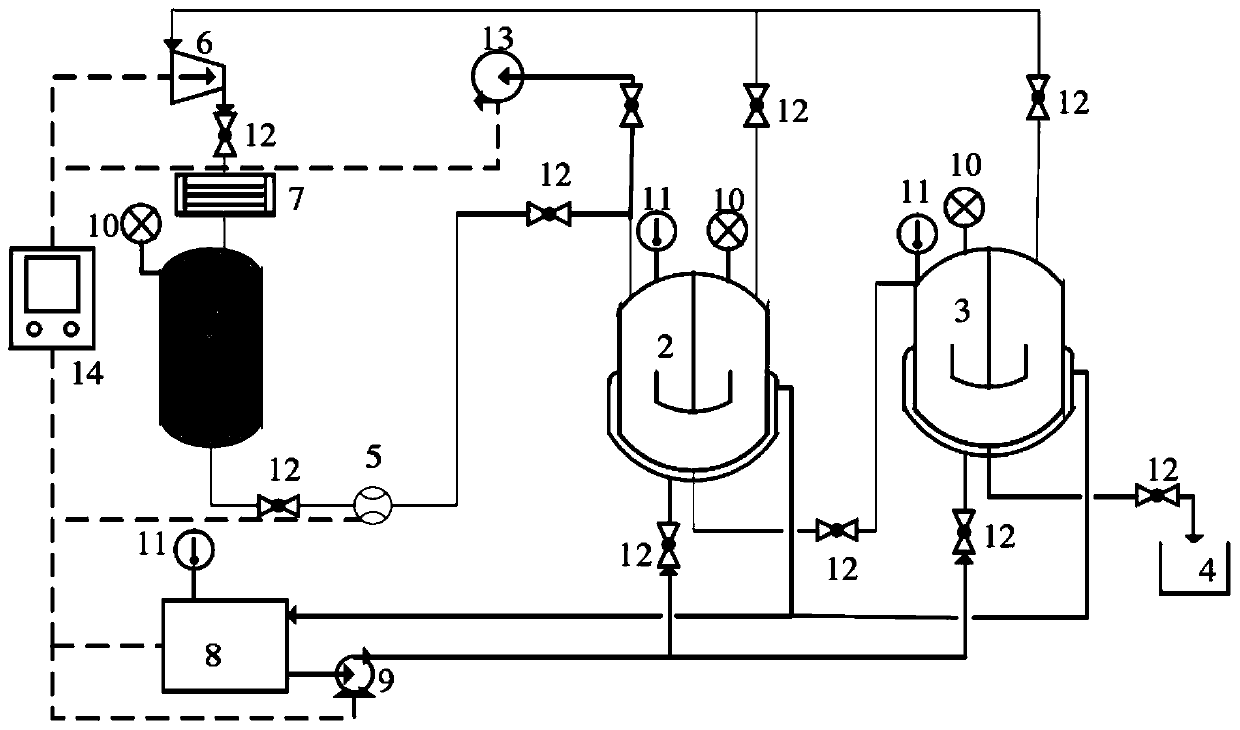

[0055] figure 1 It is a subcritical extraction device according to a specific embodiment of the present invention. Among them, 1 is a solvent storage tank; 2 is an extraction tank; 3 is a separation tank; 4 is a collection tank; 5 is a metering pump; 6 is a compressor; 7 is a condenser; 8 is a hot water tank; 9 is a hot water pump; 10 11 is a thermometer; 12 is a spherical valve; 13 is a vacuum pump; 14 is a control system.

[0056] Dried green peppercorns (place of origin: Laiwu, Shandong) to moisture content ≤ 10%, and crushed to a particle size of 50 mesh to obtain green peppercorn powder. Weigh 1kg green pepper powder and pack it into a 200-mesh material bag with an aperture, put it into the extraction kettle 2 and seal it. The first extraction step and the second extraction step were performed separately.

[0057] The first extraction step is as follows: use the vacuum pump 13 to evacuate the extraction kettle 2 to make the vacuum degree of the extraction kettle 2 reac...

Embodiment 2

[0060] Dried green peppercorns (place of origin: Laiwu, Shandong) to moisture content ≤ 10%, and crushed to a particle size of 40 mesh to obtain green peppercorn powder. Weigh 1kg green pepper powder and pack it into a 200-mesh material bag with an aperture, put it into the extraction kettle 2 and seal it. The first extraction step and the second extraction step were performed separately.

[0061] The extraction conditions of the first extraction step are as follows: the solvent is composed of dimethyl ether and entrainer 95% ethanol at a volume ratio of 3:1; the liquid-solid ratio is 5:1mL / g; the extraction pressure is 0.40MPa; the extraction temperature is 35°C ; Extraction time is 30min; All the other are with extraction embodiment 1.

[0062] The extraction conditions of the second extraction step are as follows: the solvent is propane; the liquid-solid ratio is 20:1mL / g; the extraction pressure is 1.0MPa; the extraction temperature is 30°C; the extraction time is 60min; ...

Embodiment 3

[0064] Dried green peppercorns (place of origin: Laiwu, Shandong) to moisture content ≤ 10%, and crushed to a particle size of 60 mesh to obtain green peppercorn powder. Weigh 1kg green pepper powder and pack it into a 200-mesh material bag with an aperture, put it into the extraction kettle 2 and seal it. The first extraction step and the second extraction step were performed separately.

[0065] The extraction conditions of the first extraction step are: the solvent is composed of dimethyl ether with a volume ratio of 5:1 and entrainer 95% ethanol; the liquid-solid ratio is 6:1mL / g; the extraction pressure is 0.45MPa; the extraction temperature is 45°C ; Extraction time is 20min; All the other are with extraction embodiment 1.

[0066] The extraction conditions of the second extraction step are: the solvent is propane; the liquid-solid ratio is 10:1mL / g; the extraction pressure is 1.4MPa; the extraction temperature is 25°C; the extraction time is 45min; Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com