Green prickleyash extract and preparation method thereof

A technology for green Chinese prickly ash and its extract, which is applied to the volatile oil extract of green prickly ash and its preparation field, can solve the problems that the purification step cannot exist alone, the final yield is not high, the linalool content ratio is not high and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

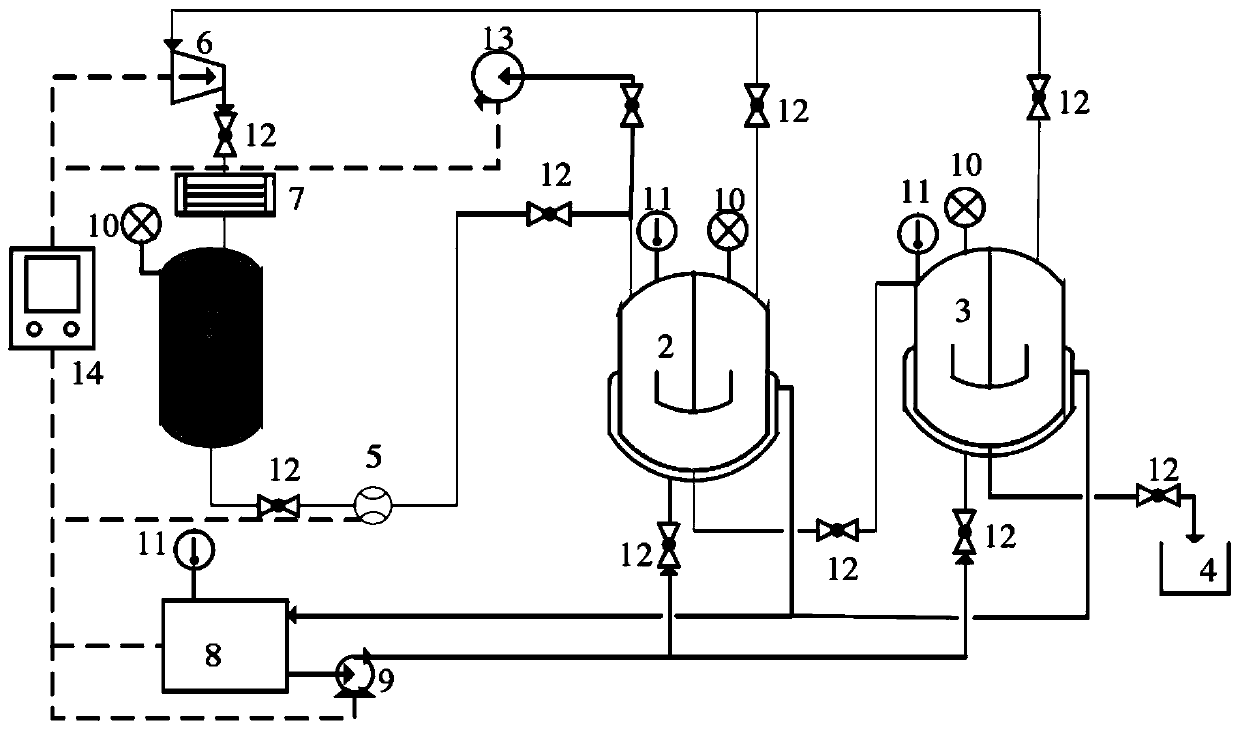

[0061] figure 1 It is a subcritical extraction device according to a specific embodiment of the present invention. Among them, 1 is a solvent storage tank; 2 is an extraction tank; 3 is a separation tank; 4 is a collection tank; 5 is a metering pump; 6 is a compressor; 7 is a condenser; 8 is a hot water tank; 9 is a hot water pump; 10 11 is a thermometer; 12 is a spherical valve; 13 is a vacuum pump; 14 is a control system.

[0062] Dried green peppercorns (place of origin: Laiwu, Shandong) to moisture content ≤ 10%, and crushed to a particle size of 50 mesh to obtain green peppercorn powder. Weigh 1kg green pepper powder and pack it into a 200-mesh material bag with an aperture, put it into the extraction kettle 2 and seal it. The first extraction step and the second extraction step were performed separately.

[0063] The first extraction step is as follows: use the vacuum pump 13 to evacuate the extraction kettle 2 to make the vacuum degree of the extraction kettle 2 reac...

Embodiment 2

[0066] Dried green peppercorns (place of origin: Laiwu, Shandong) to moisture content ≤ 10%, and crushed to a particle size of 40 mesh to obtain green peppercorn powder. Weigh 1kg green pepper powder and pack it into a 200-mesh material bag with an aperture, put it into the extraction kettle 2 and seal it. The first extraction step and the second extraction step were performed separately.

[0067] The extraction conditions of the first extraction step are as follows: the solvent is composed of dimethyl ether and entrainer 95% ethanol at a volume ratio of 3:1; the liquid-solid ratio is 5:1mL / g; the extraction pressure is 0.40MPa; the extraction temperature is 35°C ; Extraction time is 30min; All the other are with extraction embodiment 1.

[0068] The extraction conditions of the second extraction step are as follows: the solvent is propane; the liquid-solid ratio is 20:1mL / g; the extraction pressure is 1.0MPa; the extraction temperature is 30°C; the extraction time is 60min; ...

Embodiment 3

[0070] Dried green peppercorns (place of origin: Laiwu, Shandong) to moisture content ≤ 10%, and crushed to a particle size of 60 mesh to obtain green peppercorn powder. Weigh 1kg green pepper powder and pack it into a 200-mesh material bag with an aperture, put it into the extraction kettle 2 and seal it. The first extraction step and the second extraction step were performed separately.

[0071] The extraction conditions of the first extraction step are: the solvent is composed of dimethyl ether with a volume ratio of 5:1 and entrainer 95% ethanol; the liquid-solid ratio is 6:1mL / g; the extraction pressure is 0.45MPa; the extraction temperature is 45°C ; Extraction time is 20min; All the other are with extraction embodiment 1.

[0072] The extraction conditions of the second extraction step are: the solvent is propane; the liquid-solid ratio is 10:1mL / g; the extraction pressure is 1.4MPa; the extraction temperature is 25°C; the extraction time is 45min; Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com