Angle adjustable spunbond non-woven fabric production line for spinning manifold

A kind of technology of spunbond non-woven fabric and spinning box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

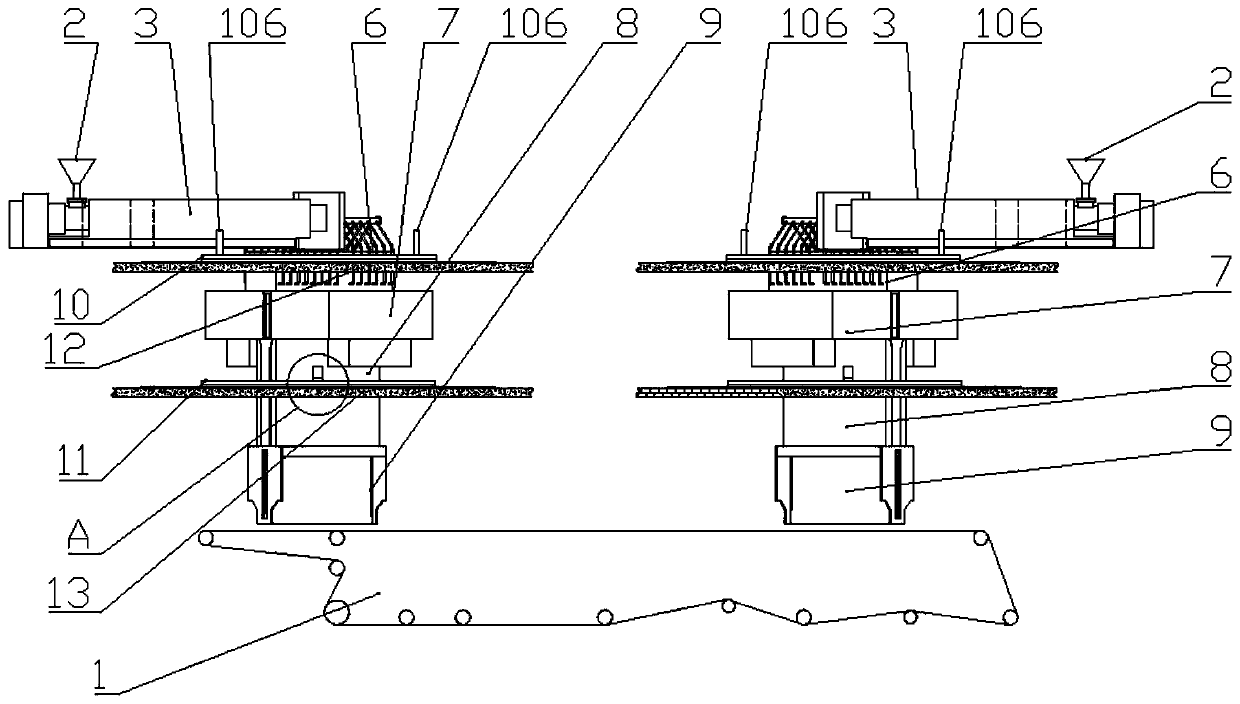

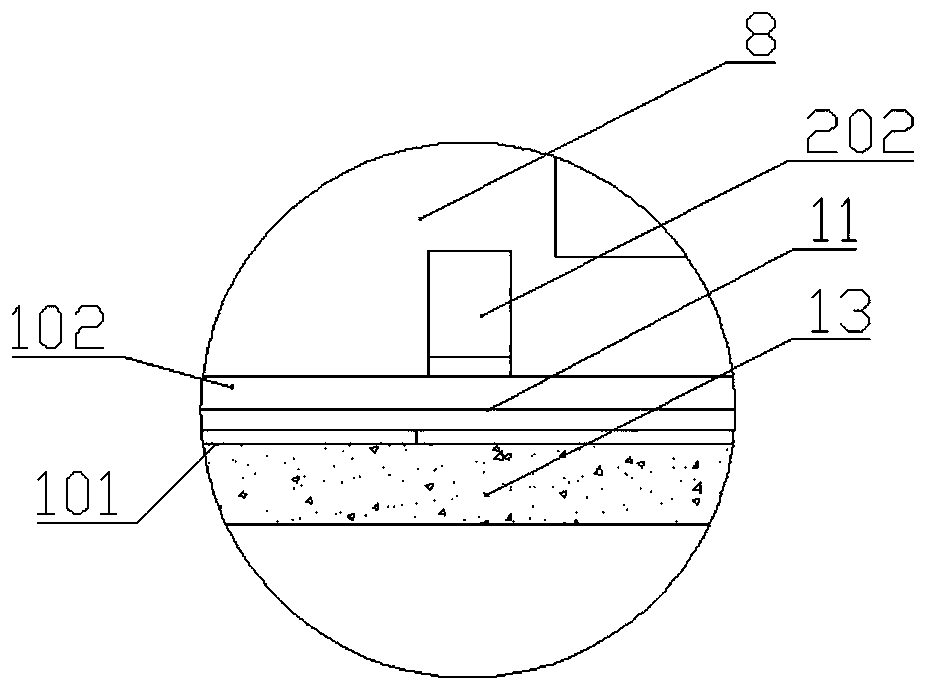

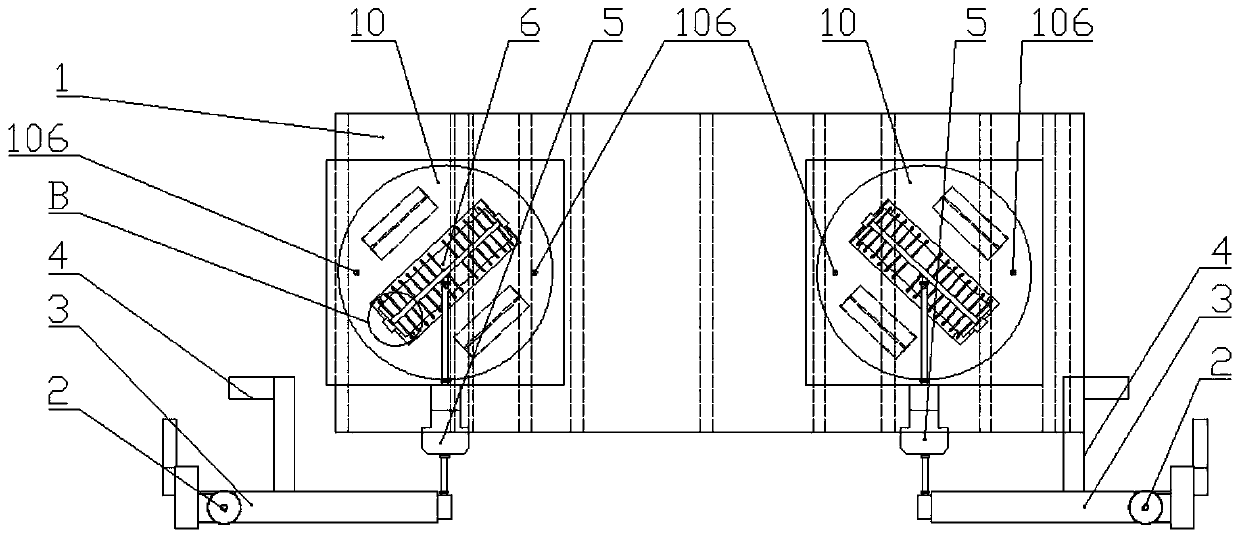

[0033] Such as Figure 1-7 As shown, a spunbonded nonwoven fabric production line with adjustable spinning box angle includes a spinning assembly, a web forming machine 1, and the spinning assembly includes a feeder 2, a screw extruder 3, and leftover materials. Device 4, filter 5, spinning box 6, cold wind box 7, drafting device 8, diffuser 9, the installation angle between the spinning assembly and the web forming machine 1 is adjusted by an angle adjusting device, so The angle adjusting device is installed on the spinning assembly through a connecting block; in this embodiment, the spinning assembly is in two groups.

[0034] The angle between the spinning assembly and the web forming machine is 45°.

[0035] In actual use of the spunbond nonwoven production line, the components of the production line are located on the first, second and third floors. The feeder 2, the screw extruder 3, the scrap recycle device 4 and the filter 5 are installed on the third floor of the product...

Embodiment 2

[0044] The structural principle of this embodiment is similar to that of embodiment 1, except that the angle adjusting device is driven by electricity. The first angle adjusting device 10 and the second angle adjusting device 11 are simultaneously driven by electric power.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com