Walking machine, and driving braking system and traveling braking method thereof

A braking system and mechanical technology, applied in the directions of roads, road repair, roads, etc., can solve the problems of brake pad breakage, high cost, and reduced displacement, and achieve the effect of avoiding brake pad breakage, simple structure and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

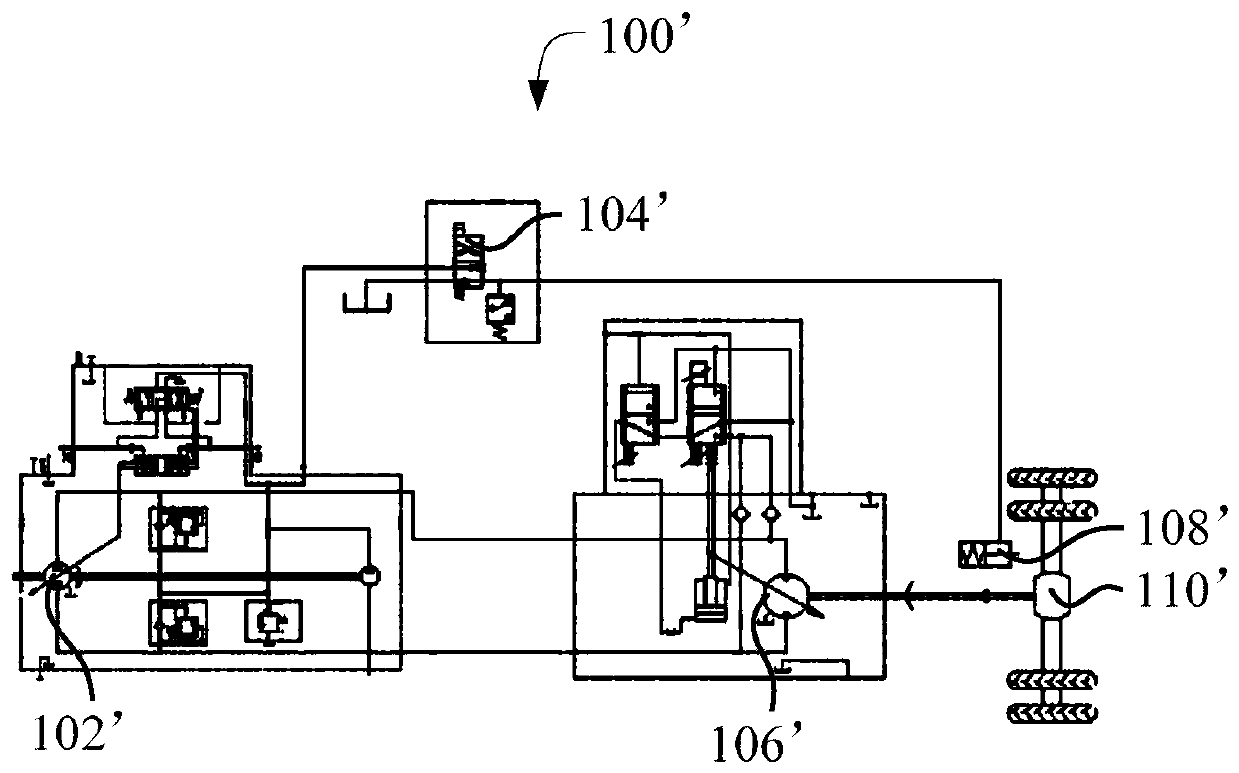

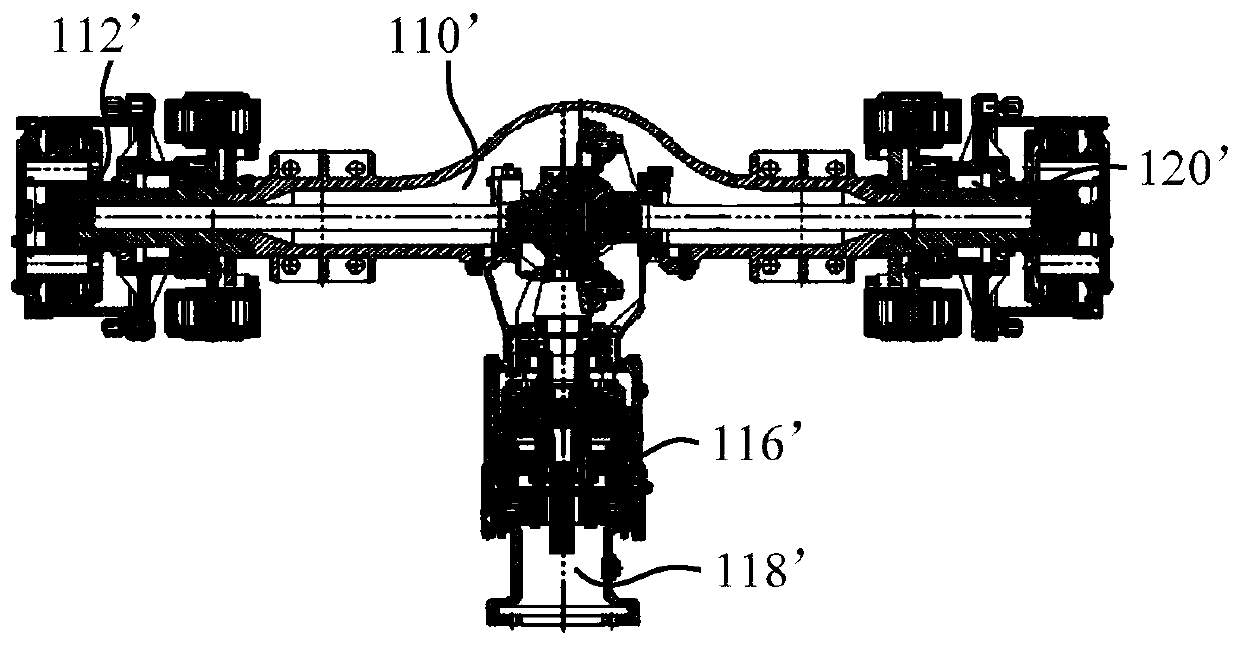

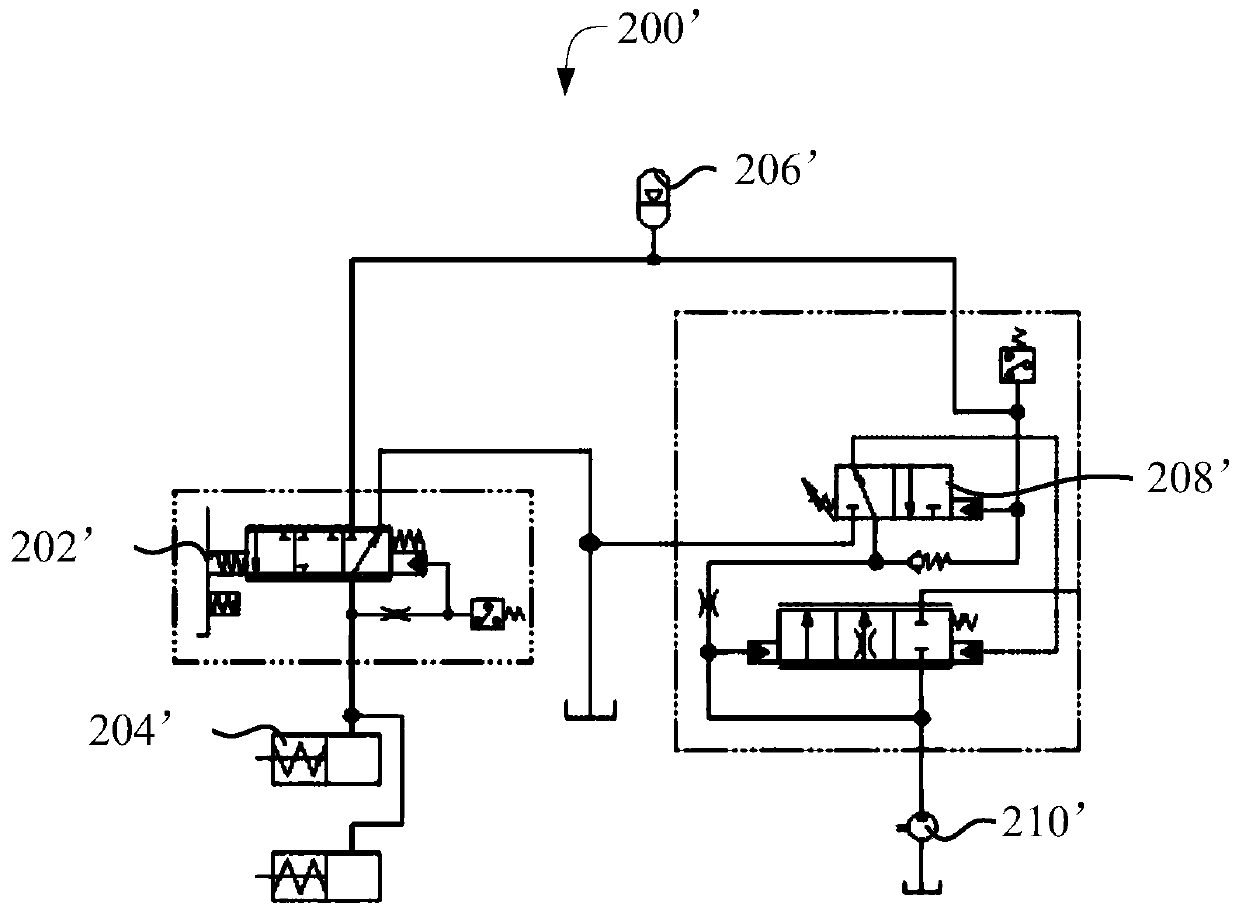

[0049] like Figure 4 As shown, according to the embodiment of the first aspect of the present invention, the present invention provides a travel braking system 100 of a mobile machine, comprising: a drive pump set 110, the drive pump set 110 includes a connected travel variable pump 112 and a charge pump 114; travel motor 130 forms a closed hydraulic circuit with the travel variable pump 112 of the drive pump group 110; the drive axle 150 is connected with the travel motor 130; the brake valve 120 is connected with the charge pump 114 of the drive pump group 110; The brake device 140 is connected with the brake valve 120, the brake device 140 is used to brake the drive axle 150, and the brake valve 120 is used to control the communication and Disconnect; the speed detection device 160 is used to detect the travel speed of the walking machine; the controller is electrically connected with the driving pump group 110, the brake valve 120 and the speed detection device 160, and w...

Embodiment 2

[0053] On the basis of Embodiment 1, further, the speed detection device 160 is a speed sensor, which is provided on the travel motor 130 or the driving axle 150 .

[0054] In this embodiment, the rotation of the rotating shaft of the traveling motor 130 drives the rotation of the rear axle in the drive axle 150, thereby realizing the traveling of the traveling machine. Therefore, the rotating speed of the traveling motor 130 or the rotating speed of the driving axle 150 can reflect the speed of the traveling machine. The travel speed, and further, the speed sensor is provided on the travel motor 130 or the transaxle 150 to accurately detect the travel speed of the travel machine.

Embodiment 3

[0056] On the basis of Embodiment 1, further, the speed detection device 160 is a strategy controller, which determines the traveling speed of the traveling machine according to the operating parameters of the traveling machine.

[0057] In this embodiment, various operating parameters of the walking machine can also reflect the running speed of the walking machine. Therefore, the strategy controller can be used to obtain the running parameters of the walking machine, and the running speed of the walking machine can be obtained through calculation.

[0058] Specifically, for example, the traveling speed of the traveling machine is calculated based on the torque on the rear axle in the transaxle 150 , the torque on the traveling motor 130 , and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com