Top pressing type sound-proof door

A sound insulation door and top pressure technology, applied in the direction of sound insulation doors/windows, sealing devices, etc., can solve the problems of poor sealing and sound insulation effect of sound insulation doors, easy rupture and damage of rubber sealing strips, unsatisfactory sound insulation effect, etc., and achieve excellent sealing. The effect of sealing and sound insulation is better, which is beneficial to the promotion and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

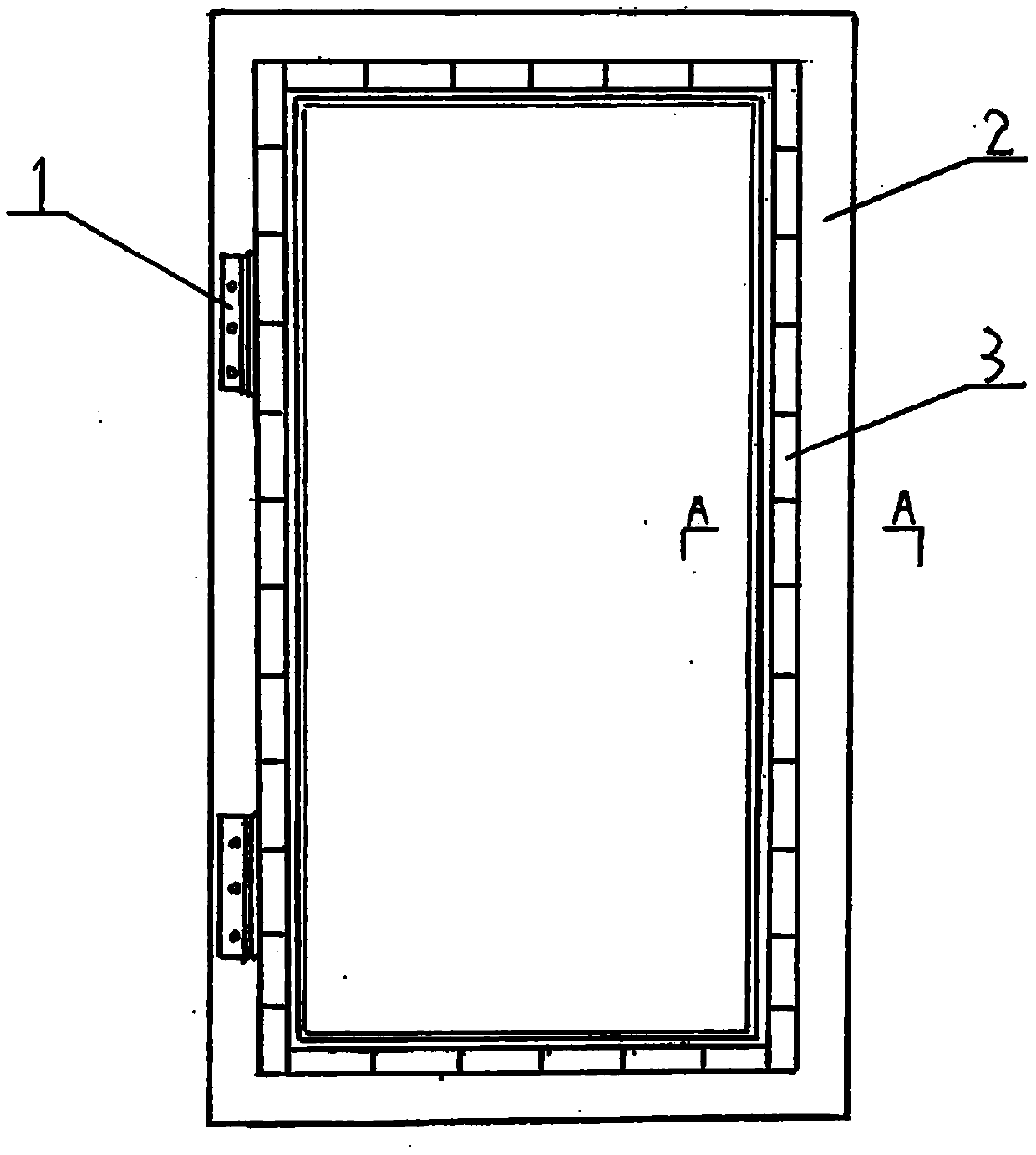

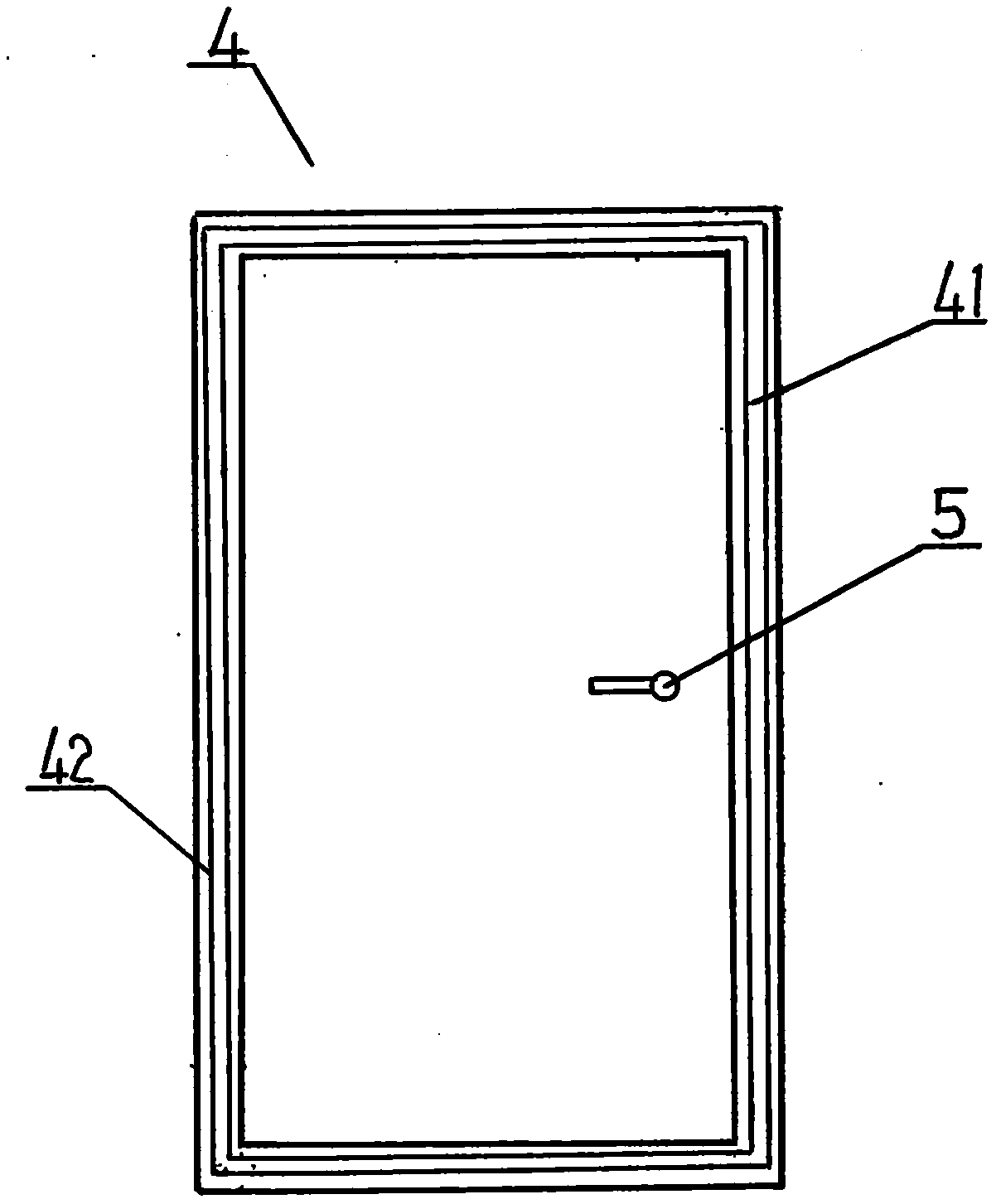

[0028] Embodiment 1: as Figure 1 to Figure 6 As shown, a top-pressure soundproof door includes a hinge 1 and a door frame sealing strip, wherein:

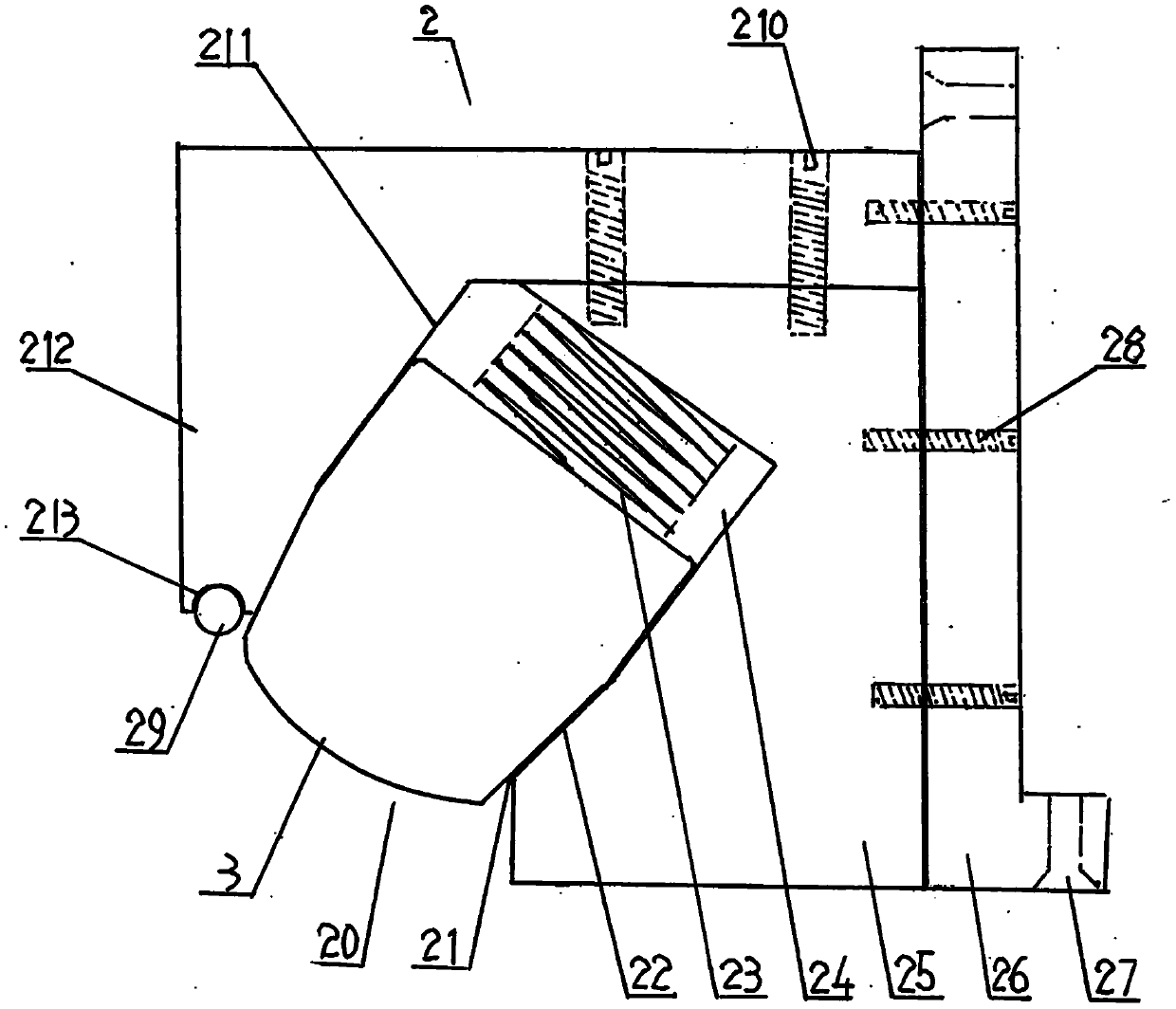

[0029] Door frame body 2: the inner side of the front end surface of the door frame body forms an L-shaped angle to form a door card slot 20 . The door frame body inside the corner of the door card slot is provided with a sealed chamber 24, and the sealing opening 21 of the sealed chamber is located at the corner of the door card slot. The front end faces of many rubber sound-insulating blocks 3 connected in series protrude from the sealing opening in the slot of the door. The rear part of the rubber sound-insulating block is located in the sealed chamber, and a top pressure spring 23 is arranged between the rear end surface of each rubber sound-insulated block and the rear end surface of the corresponding sealed chamber. The door frame body can be made of aluminum profiles.

[0030] Rubber sound-insulating block 3: it is a str...

Embodiment 2

[0037] Embodiment 2: as Figure 1 to Figure 6 As shown, a top-pressure soundproof door includes a hinge 1 and a door frame sealing strip 29, wherein:

[0038]Door frame 2: The door frame is composed of a main frame 25 , an inner frame 212 and an outer frame 26 . The main frame is located at the front side of the door frame, the inner frame is located at the inner side of the door frame, and the outer frame is located at the outer side of the main frame and the inner frame. The rear end of the main frame and the front end side of the inner frame body are connected into one body through several second bolts 210 . The inner side of the outer frame is integrated with the outer side of the main frame and the inner frame through several first bolts 28 . The two ends of the outer frame body can be provided with screw holes 27, so as to facilitate the integration with the corresponding wall door opening by bolts. The front end of the inner frame is arranged in the middle of the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com