Analysis method and device for self-supporting fracture conductivity

A technology of conductivity and analysis method, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of poor accuracy of conductivity, large difference in fluidity, and conductivity test of self-supporting fractures. Poor accuracy and other problems, to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

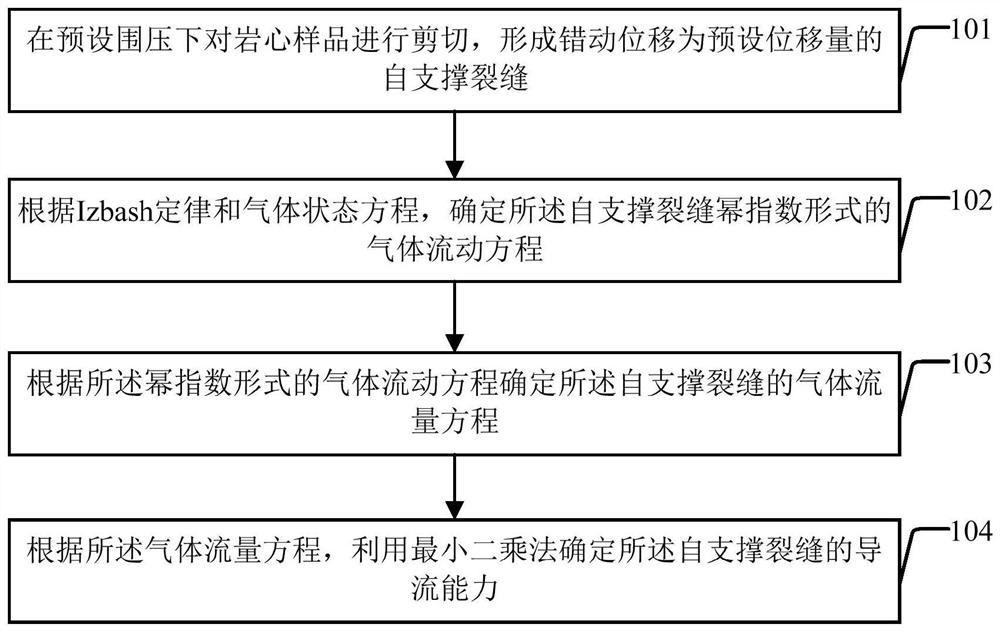

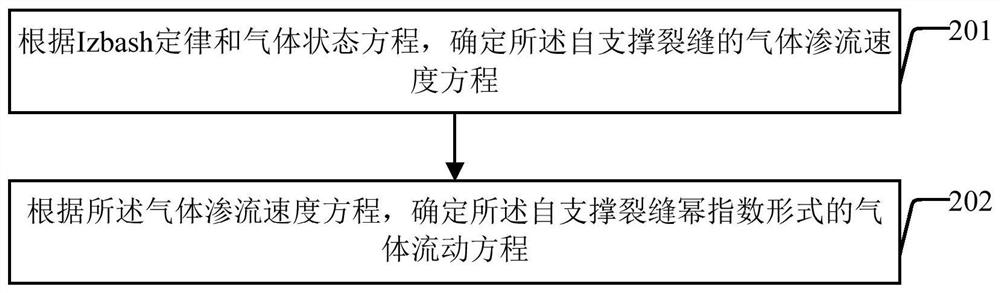

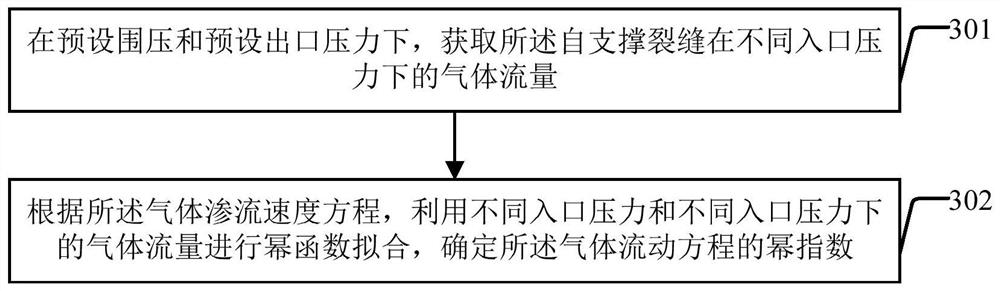

Method used

Image

Examples

Embodiment Construction

[0037] Confining pressure refers to the pressure exerted on it by the surrounding rock mass of the rock. The confining pressure of rocks deep underground, mainly

[0040] The preset displacement amount is a preset displacement amount, for example, the preset displacement amount can be set to 0.1mm.

[0041] In a further embodiment, the core sample is a cylindrical core sample. In a further example

[0055]

[0058]

[0061]

[0064]

[0073]

[0075] Y=k

[0079]

[0085] Step 403, determining the conductivity of the self-supporting fracture according to the minimum value of the square sum function.

[0089]

[0092]

[0094]

[0100] The embodiment of the present invention also provides a self-supporting fracture conductivity analysis device, such as the following embodiments

[0106] The flow conductivity determination module 604 is configured to use the least squares method to determine the flow rate according to the gas flow equation.

[0117] FIG. 9 shows the determination o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com