TEM sample support film and its preparation method, TEM sample analysis method

A technology that supports membranes and samples, applied in the semiconductor field, can solve problems affecting analysis results and achieve the effect of less time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

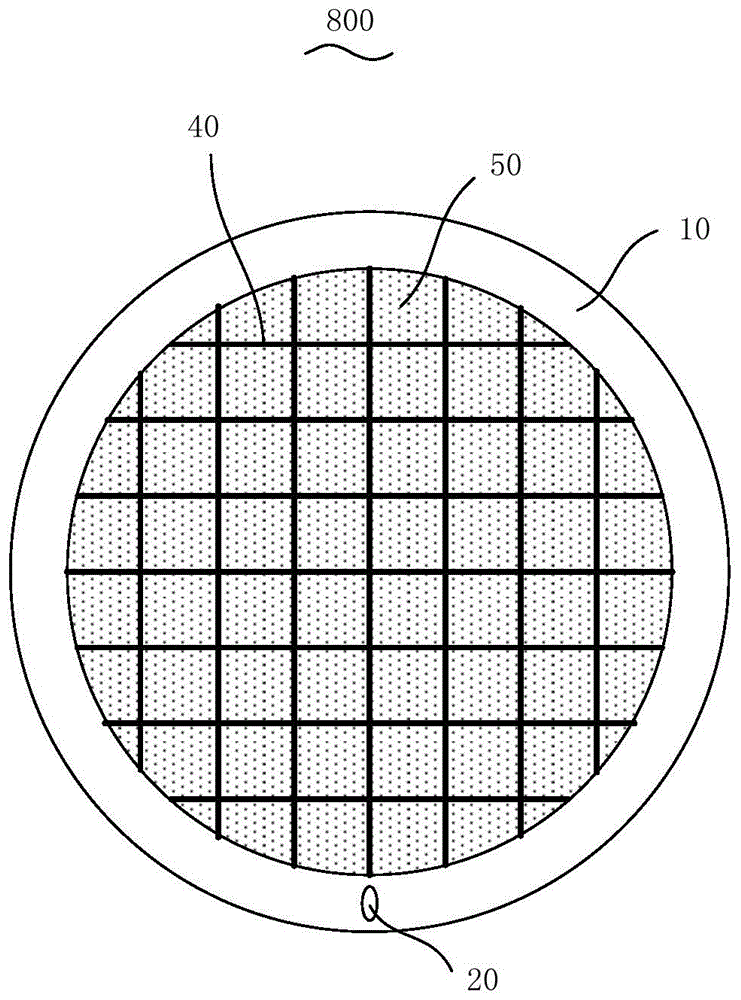

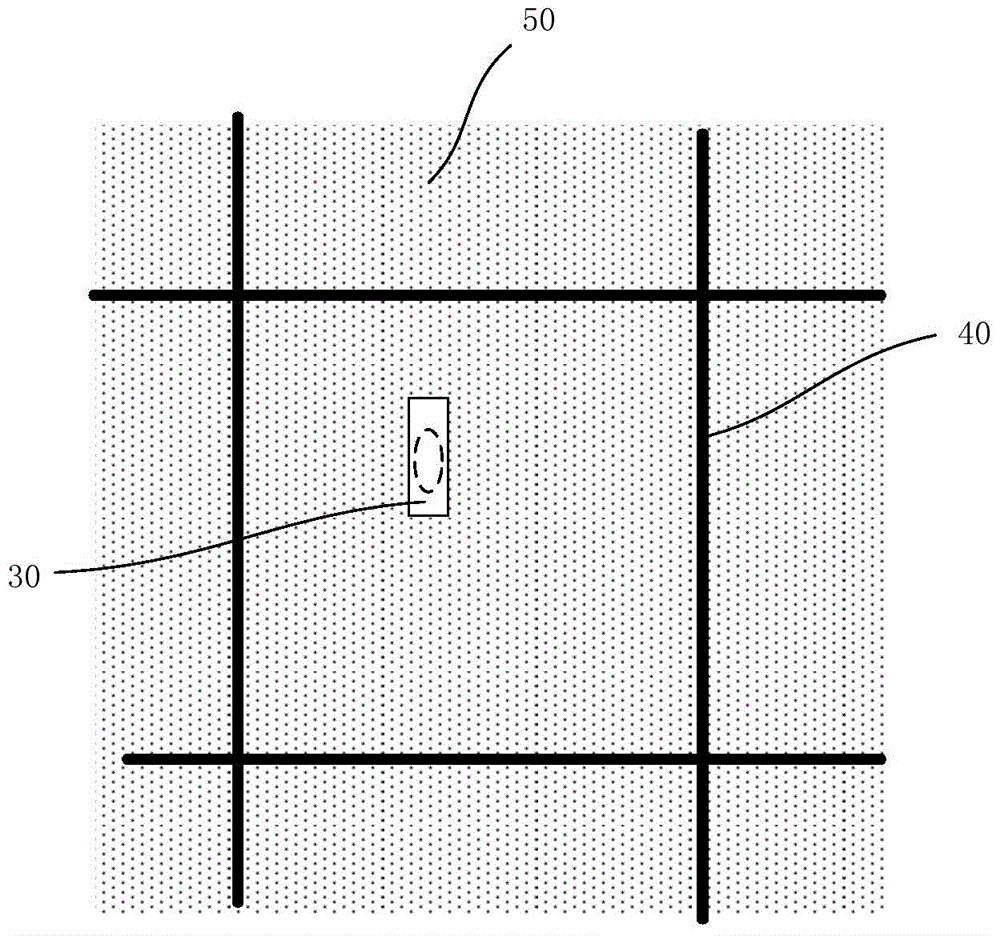

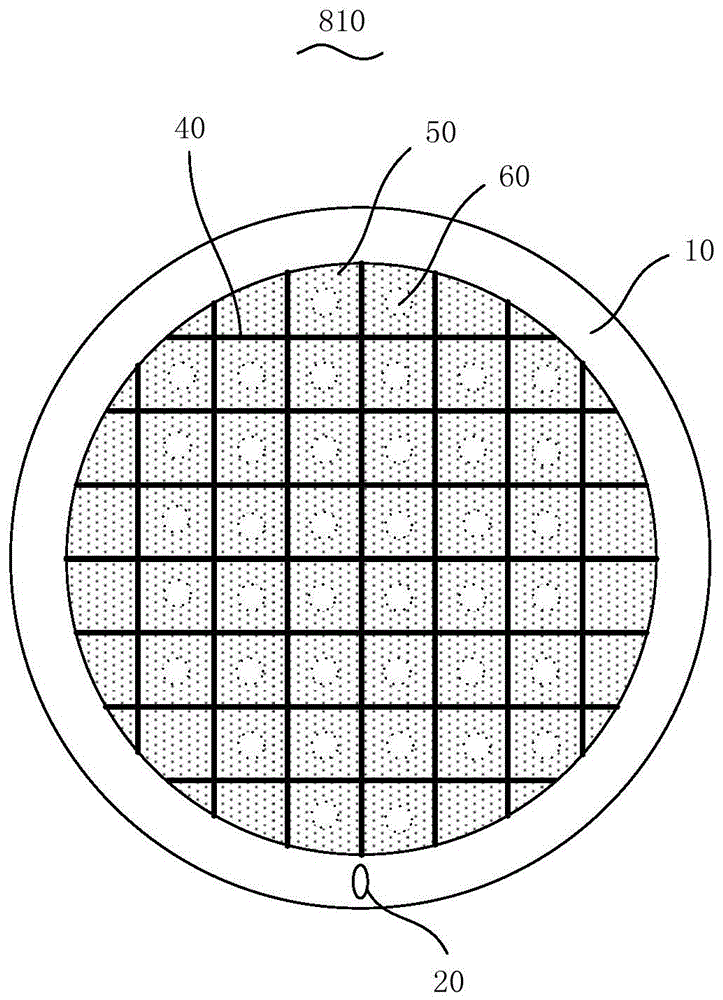

[0054]The inventor of the present invention has improved the TEM sample carrying network support film in the traditional technology through many tests and summaries, and provided a new TEM sample carrying network support film, including: a carrying component, and the carrying component is set There is a hollowed out area, and the hollowed out area includes a plurality of hollowed out parts; a carbon film is covered on the hollowed out area; wherein, at least one of the carbon films covered on the hollowed out part is provided with a sample hole.

[0055] When the new TEM sample grid support membrane is used for TEM analysis, the TEM sample is placed on the sample hole, and the target area to be analyzed in the TEM sample is aligned with the sample hole, so that the TEM analysis is carried out At this time, the carbon film will not become the background of the TEM sample, affecting the observation and analysis of the TEM analysis. The carbon film on the edge of the sample hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com