Rapid analysis and sampling device for micro-components

A technology for rapid analysis and sampling device, applied in measurement devices, analysis materials, analysis of gas mixtures, etc., can solve the problems of poor reproducibility, large deviation and labor consumption of analysis results, and achieve saving sample gas consumption, rapid analysis, and improved reproduction. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

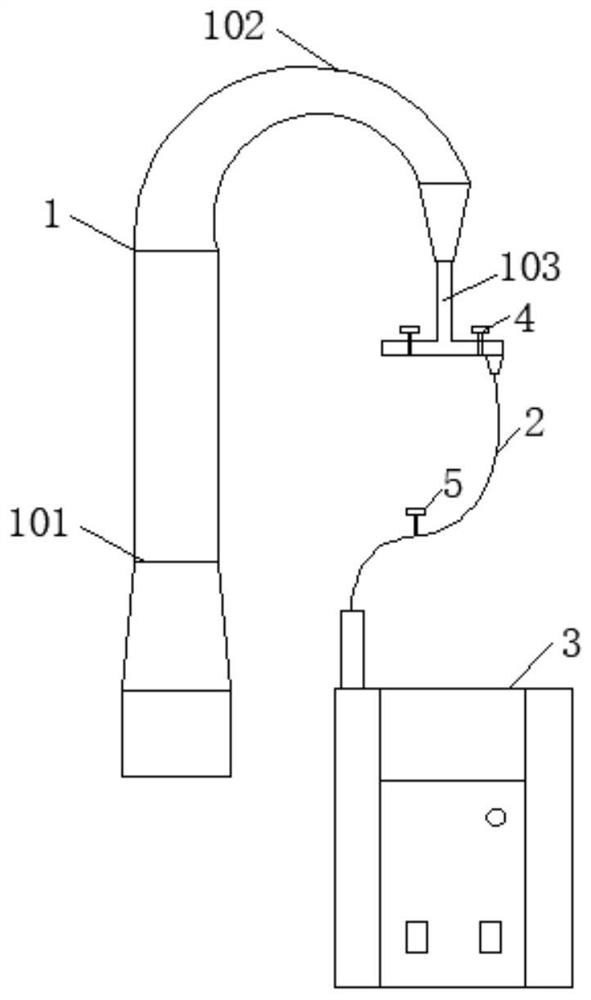

[0008] Such as figure 1 As shown, a rapid analysis and sampling device for microcomponents includes a leaching reducing joint 1, a sample gas regulating tube 2 and a micro analyzer 3, and the leaching reducing joint 1 includes a first connection reducing joint 101, a second Two connecting reducing elbow 102 and the third connecting tee joint 103, the outlet of the first connecting reducing joint 101 is connected with the inlet of the second connecting reducing elbow 102, the outlet of the second connecting reducing elbow 102 is connected with the third One interface of the connection tee joint 103 is connected, one of the other two interfaces of the third connection tee joint 103 is connected to the inlet of the sample gas regulating pipe 2, and the other two interfaces of the third connection tee joint 103 are respectively provided with A f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com