Methods and system for determining engine air-fuel ratio imbalance

一种发动机、操作方法的技术,应用在发动机元件、燃烧发动机、发动机点火等方向,能够解决气缸空燃比不平衡等问题,达到减少排放物的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

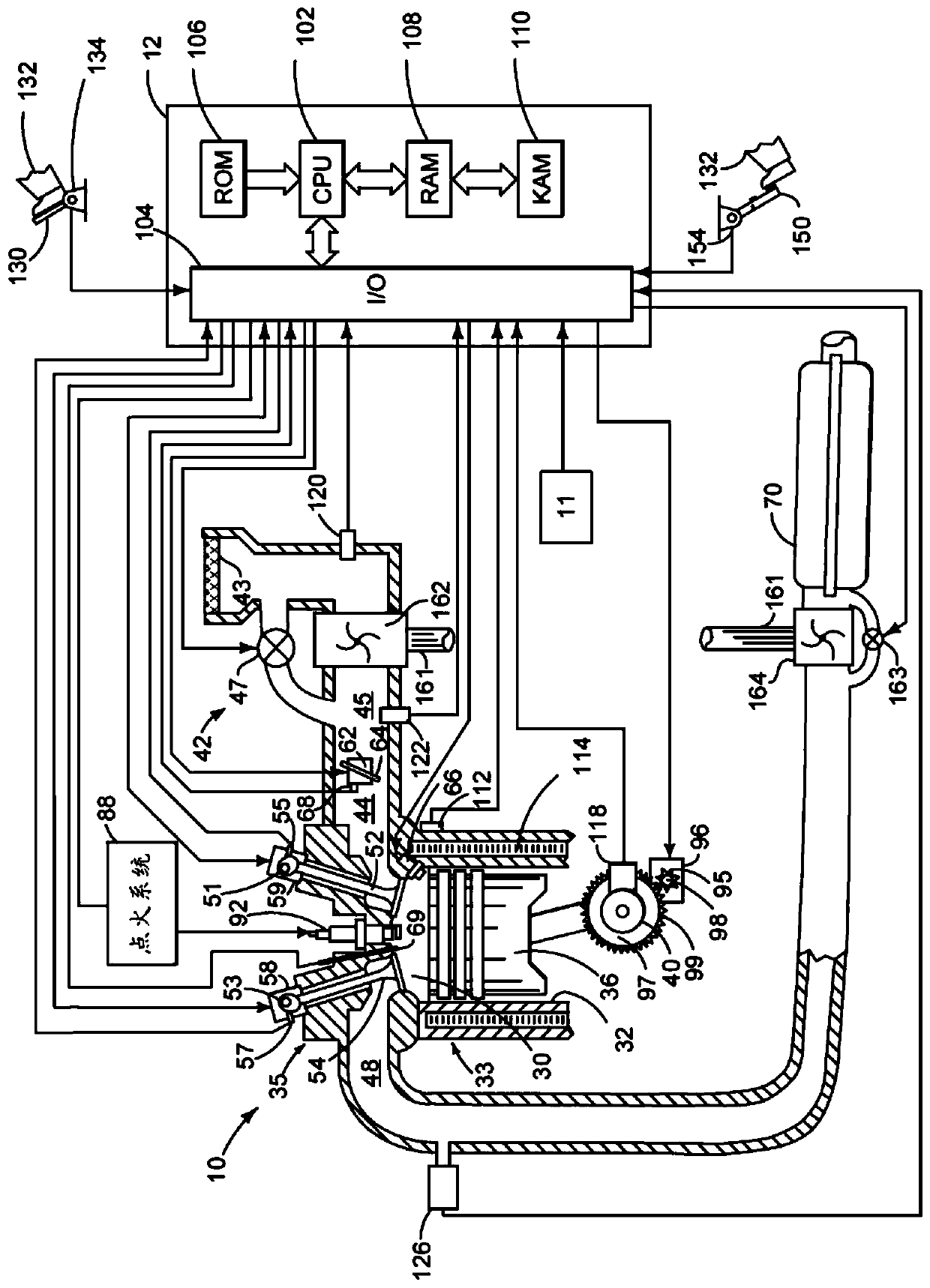

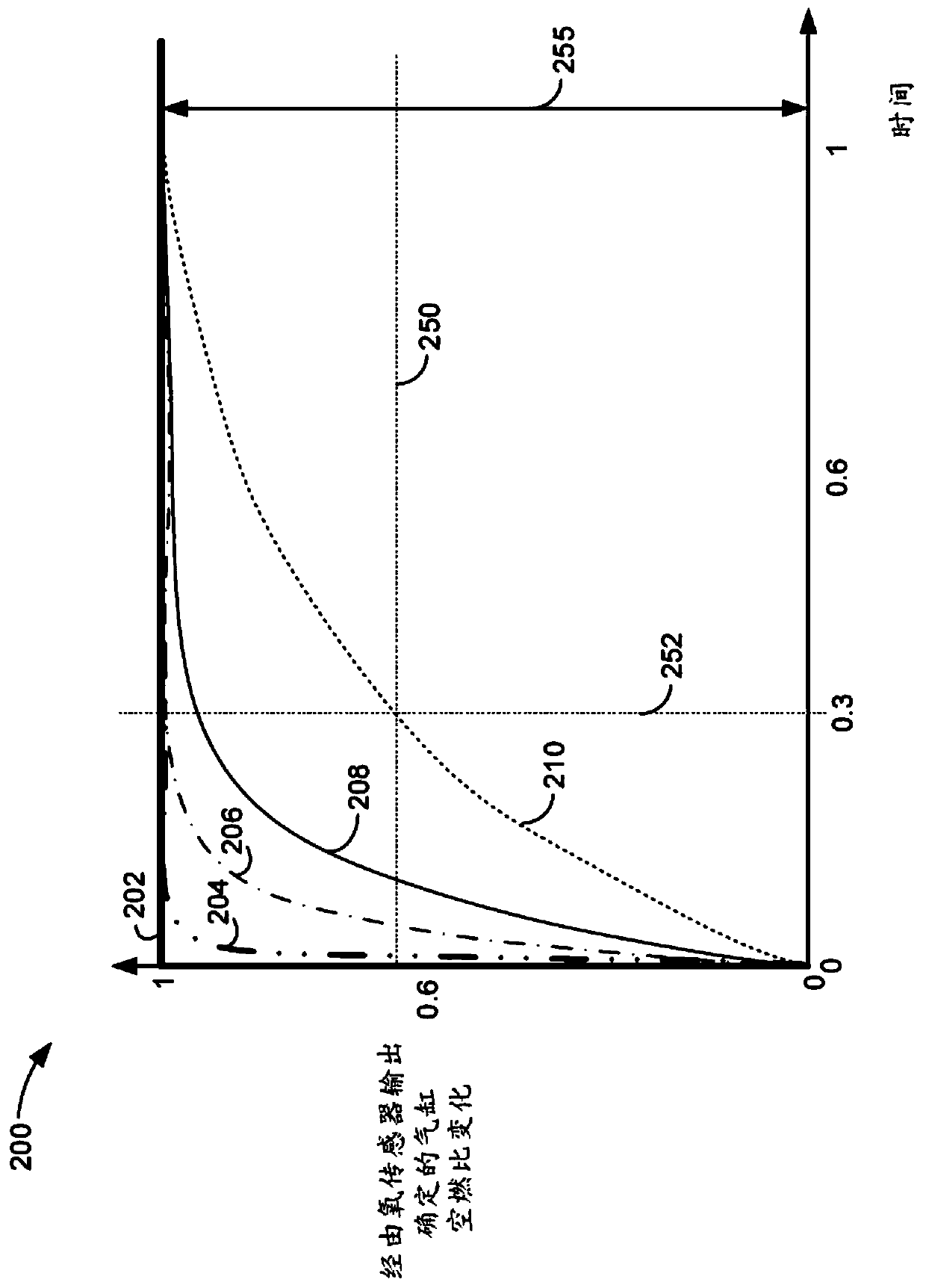

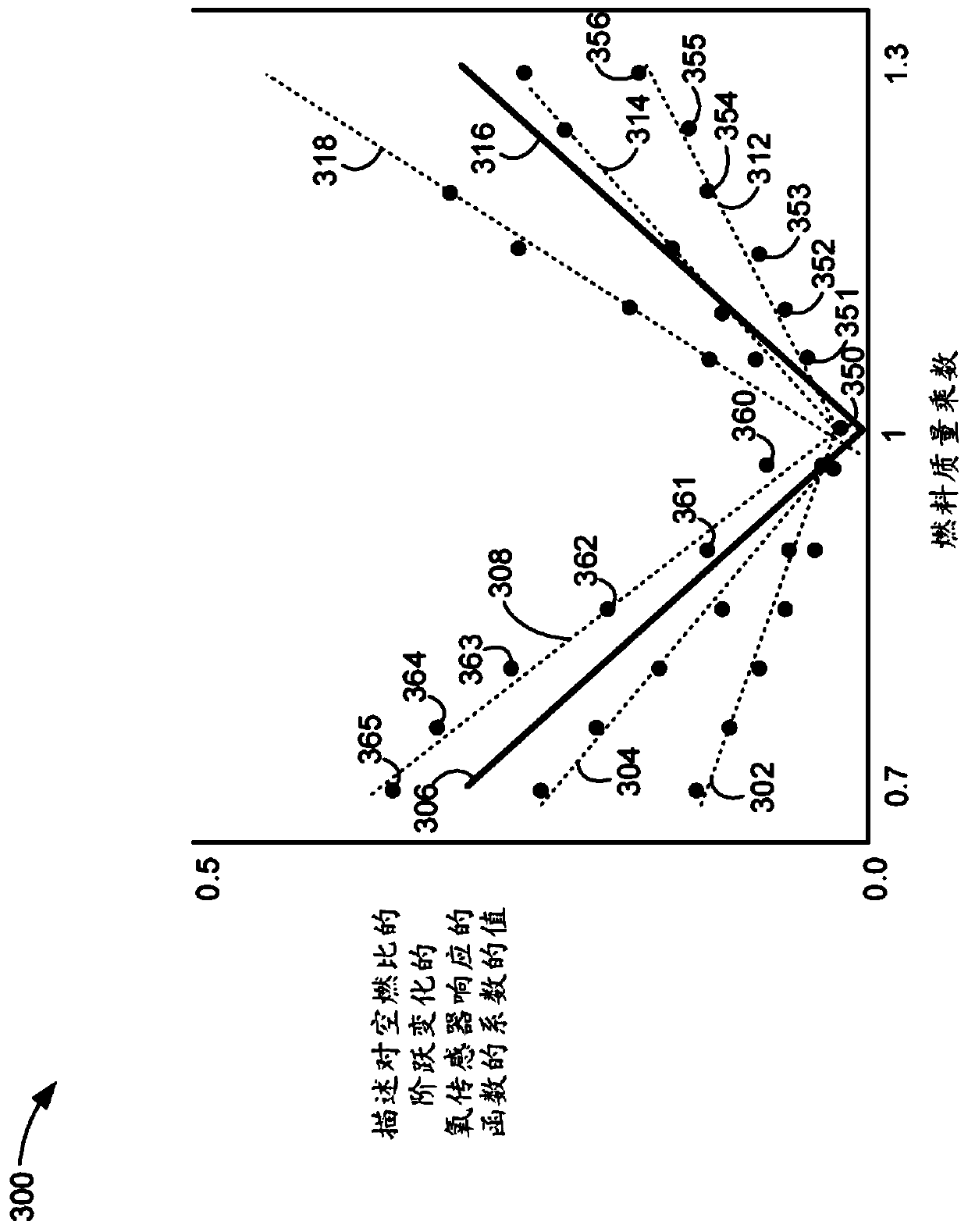

[0014] This instruction relates to operating a vehicle's internal combustion engine. engine can be figure 1 type shown. Engines may be operated with conditions between one or more cylinders that may result in increased engine emissions. Imbalance can be detected via a step change in the air-fuel ratio input to the engine cylinders, as in figure 2 shown. The oxygen sensor output in response to a step input in air-fuel ratio or lambda can be applied to generate a straight line showing the relationship between the coefficients of the function and the air-fuel ratio multiplier, as image 3 shown. One or more lines can be the basis for determining the cylinder air-fuel ratio imbalance, such as Figure 4 depicted. exist Figure 5 and Figure 6 A method for determining and compensating for an air-fuel ratio imbalance in an engine cylinder is shown in the method of .

[0015] refer to figure 1 , an internal combustion engine 10 comprising one or more cylinders is controlled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com