Air-assisted injection system for engine, cold start control method and vehicle

An engine starting and air-assisted technology, which is applied to engine starting, engine components, combustion engines, etc., can solve the problems of unfavorable combustion of heavy-duty methanol engines, difficulty in raising the temperature of the intake manifold, and high intake pressure, and achieves a favorable air-conditioning system. The effect of fuel ratio control, ensuring success rate and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

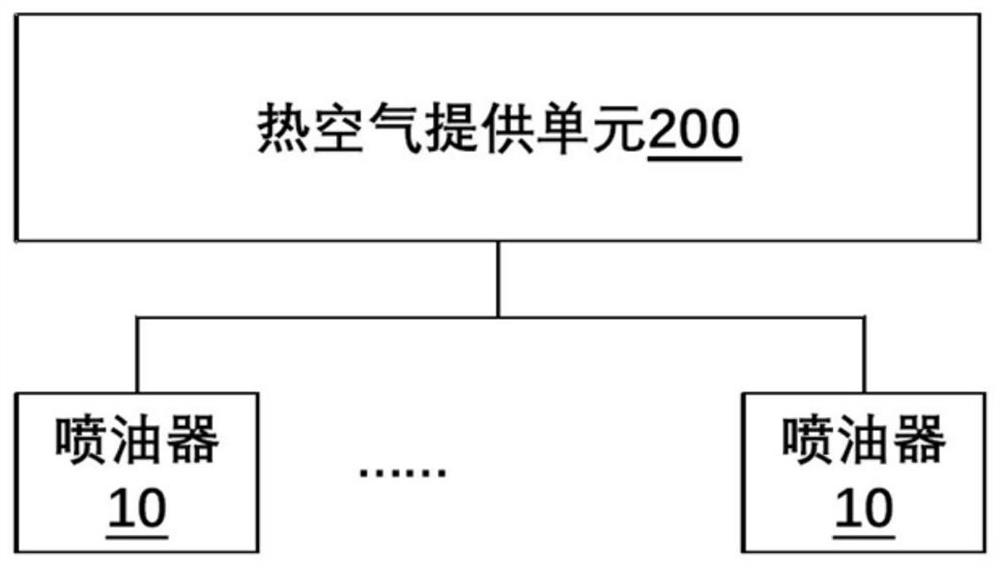

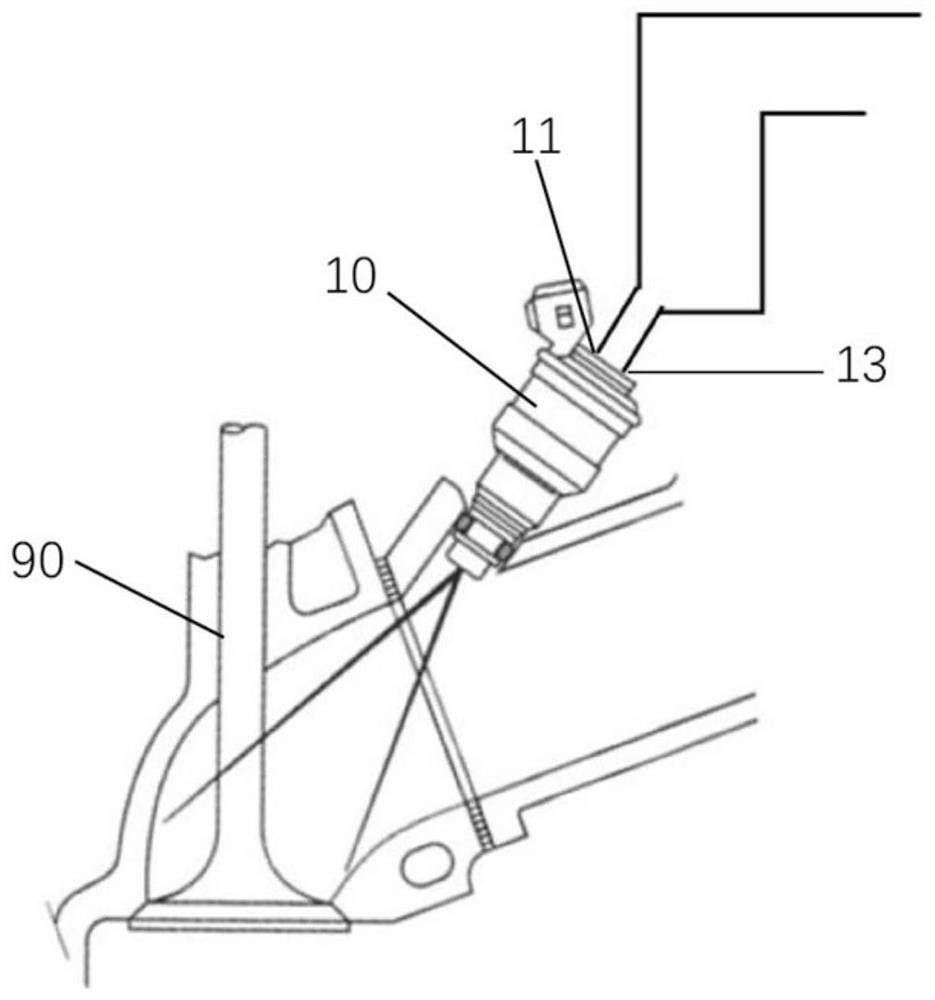

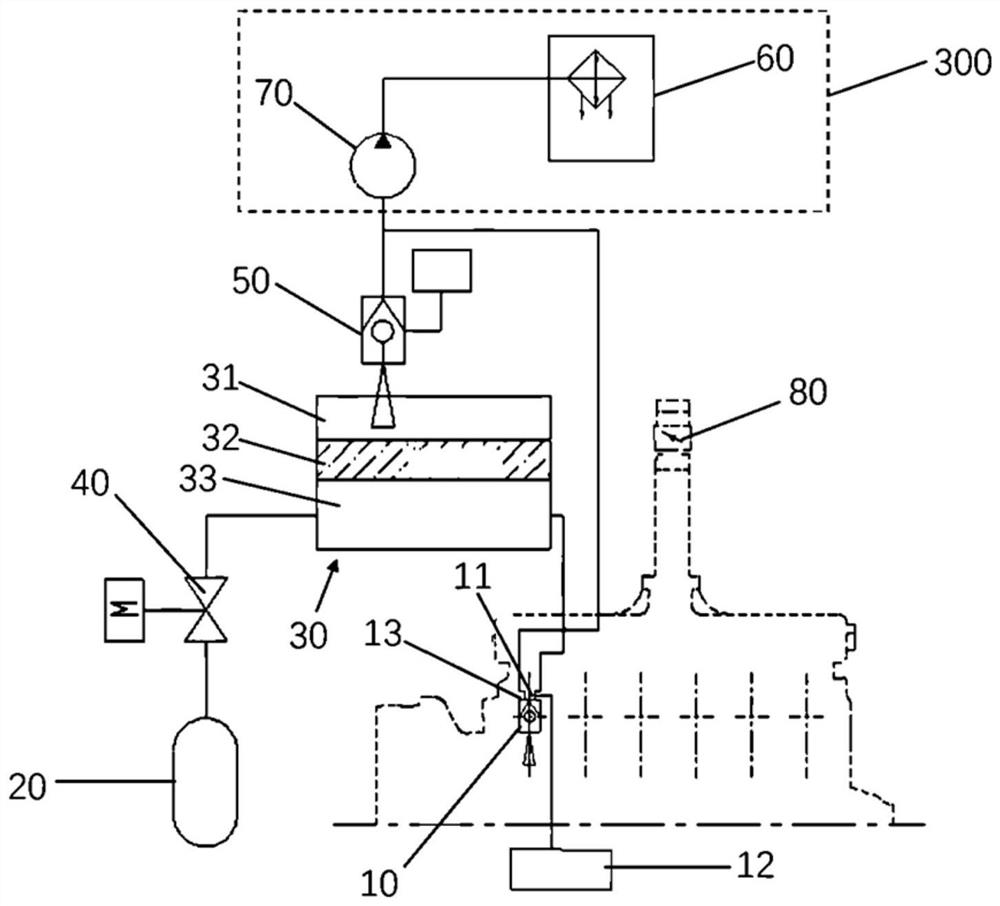

[0039] figure 1 is a connection block diagram of an air-assisted injection system according to one embodiment of the present invention. Such as figure 1 As shown, in one embodiment, the air assisted injection system includes a plurality of injectors 10 and a hot air supply unit 200 . Each injector 10 is provided with an air channel 11 and an air escape port 12, and the air escape port 12 is controlled to communicate with or block the outside world. The hot air supply unit 200 is connected to the air duct 11, and the air-assisted injection system is configured to activate the hot air supply unit 200 and open the air escape port 12 when receiving the preheating start command, so that the hot air supply unit 200 supplies each The fuel injector 10 supplies heated air to exhaust the cool air from the air escape port 12 and closes the air escape port 12 upon receiving a warm-up end command.

[0040] In this embodiment, in the preheating stage (that is, when the engine is not star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com