A measuring device and measuring method for electron gun beam spot performance

A measurement device and measurement method technology, applied in the measurement device, radiation measurement, X/γ/cosmic radiation measurement and other directions, can solve the influence of poor measurement accuracy and uncertainty of measurement accuracy, quantitatively calculate the beam spot size and Analyze problems such as difficulty in uniformity, and achieve the effects of simple operation, elimination of charge accumulation, and simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

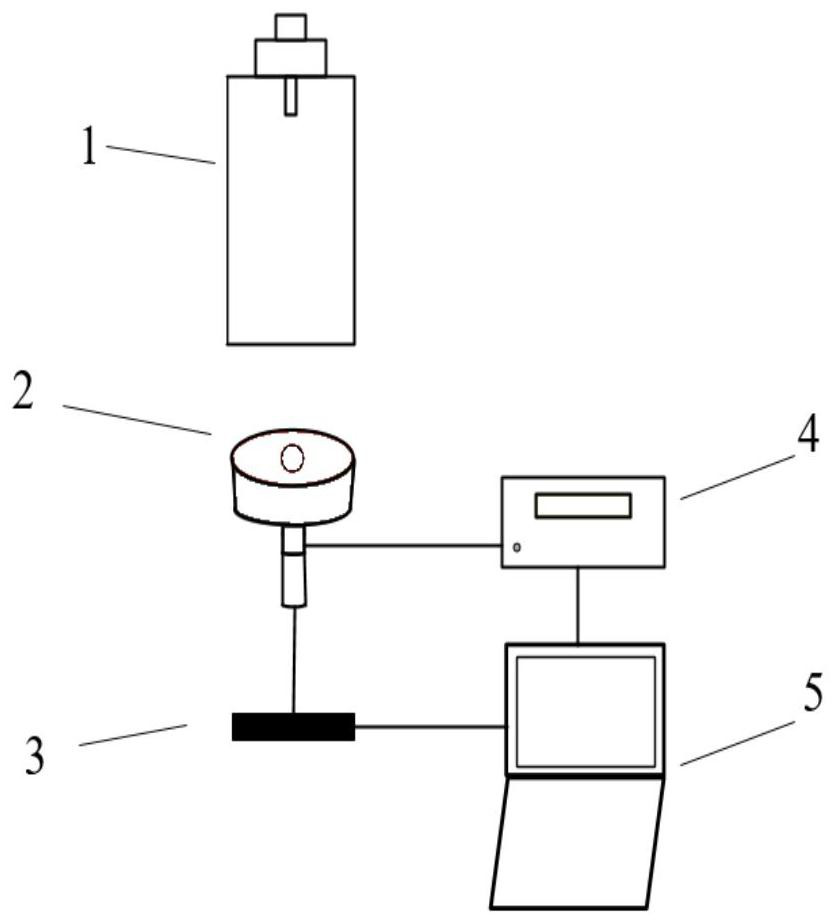

[0033] Embodiment one: if figure 1 As shown, the electron gun beam spot performance measuring device provided in this embodiment includes a charge-controlled electron gun 1 , a Faraday cup 2 , a precision displacement stage 3 , a picoammeter 4 and a computer 5 .

[0034] The connection relationship among the various components is as follows: the charge control electron gun 1 is located above the Faraday cup 2 . The Faraday cup 2 is fixedly connected to the precision translation platform 3 and moves synchronously with the precision translation platform 3 . One end of the picoammeter 4 is connected with the Faraday cup 2, and the other end is communicated with the computer 5.

[0035] Specifically, the picoammeter 4 can be connected to the Faraday cup 3 through a BNC line, and the picoammeter 4 can communicate with the computer 5 by means of a general interface bus GPIB or a serial interface line RS-232.

[0036] The composition and function of each component are as follows: ...

Embodiment 2

[0050] Embodiment 2: This embodiment discloses a method for measuring the beam spot performance of an electron gun. The measurement method uses the device for measuring the beam spot performance of an electron gun described in Embodiment 1 to work, including the following steps:

[0051] Step 1, setting the working parameters of the charge control electron gun 1 , the working parameters include accelerating voltage, cathode current and grid voltage.

[0052] Step 2, when the indication of the picoammeter 4 basically does not change, the charge control electron gun 1 is in a stable working state, at this time, the movement of the precision displacement table 3 is controlled, and the Faraday cup 2 is moved to the center point of the electron beam spot directly below;

[0053] This step specifically includes:

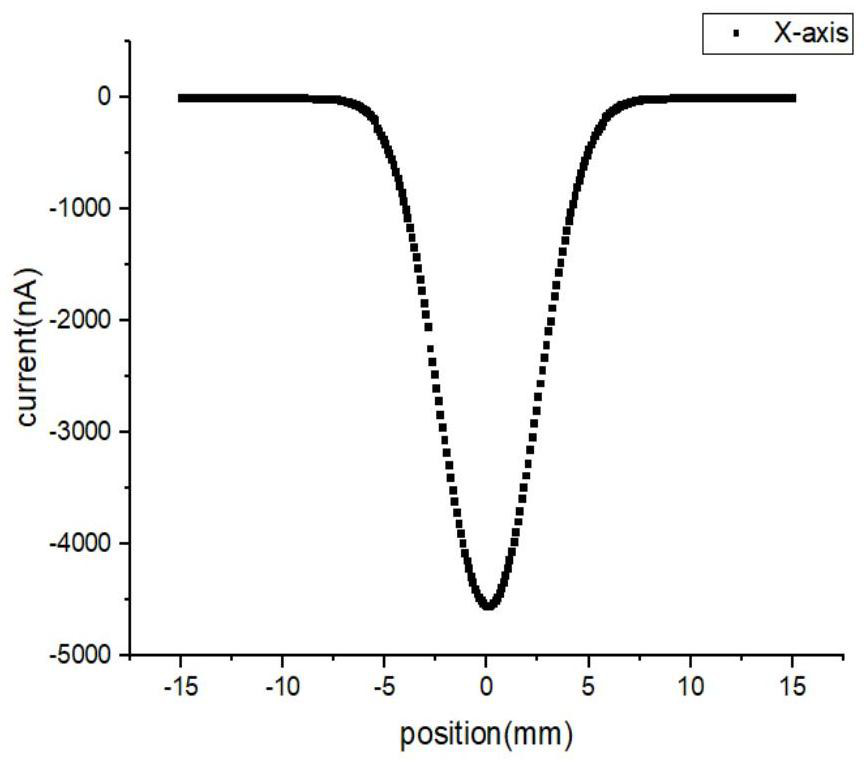

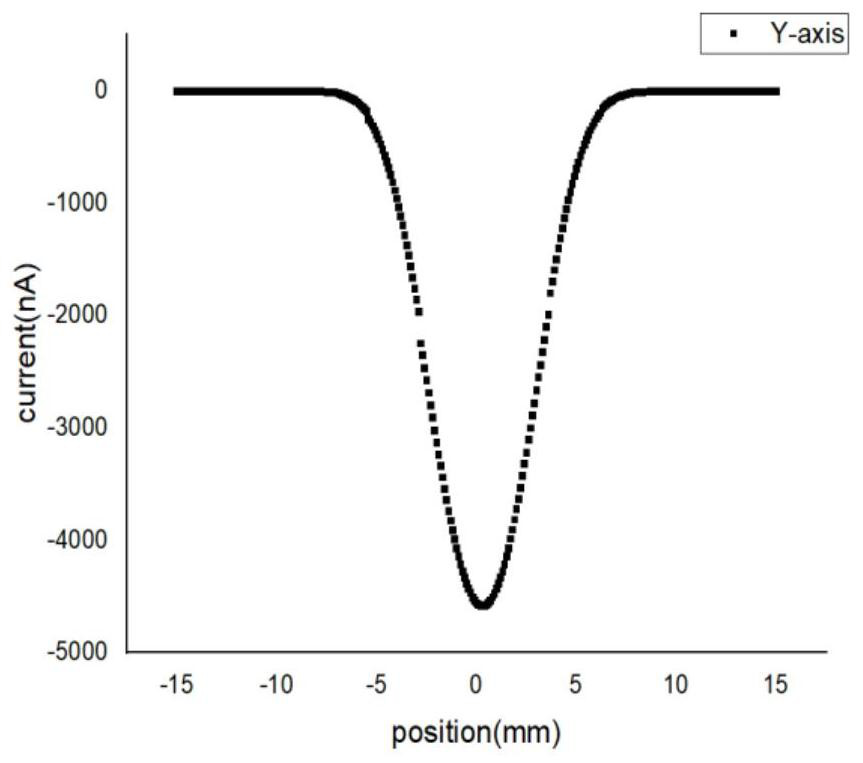

[0054] Step 2-1, controlling the movement of the precision translation stage 3 along the X-axis and the Y-axis, so that the Faraday cup 2 reaches near the center point of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com