A Current Sharing Method Combining Preset Bias Angle and Shared Synchronization Signal

A technology of synchronization signal and bias angle, which is applied in the output power conversion device, the conversion of AC power input to DC power output, electrical components, etc., can solve the problem of not considering hardware differences, etc. The effect of small perturbations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

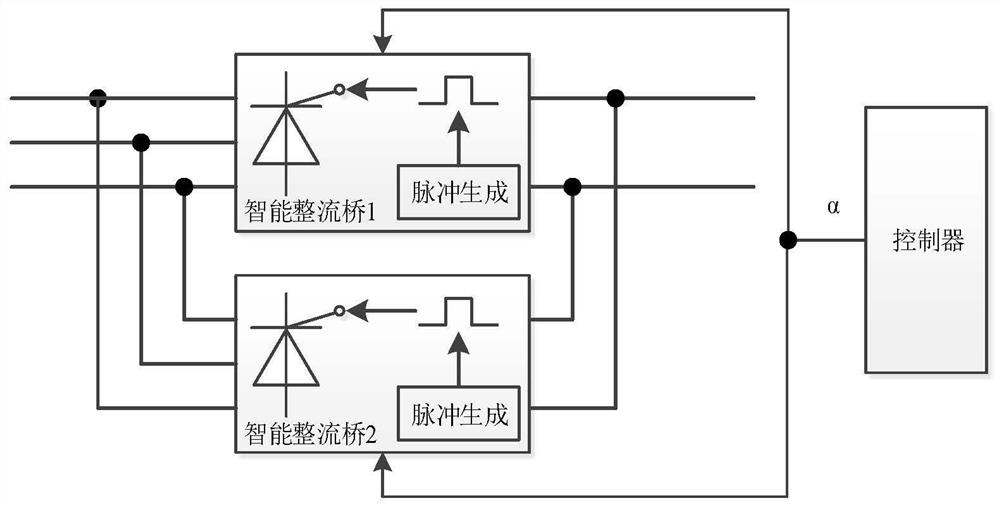

[0043] Such as Figure 1-Figure 7 As shown, the present invention uses the same hardware as the patent application No. 201910223958.X, and shares the synchronization information and synchronization bias angle of all parallel smart rectifier bridges through the communication network.

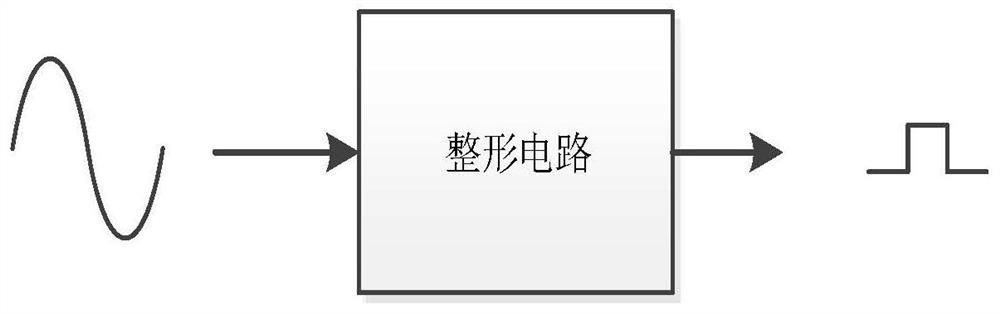

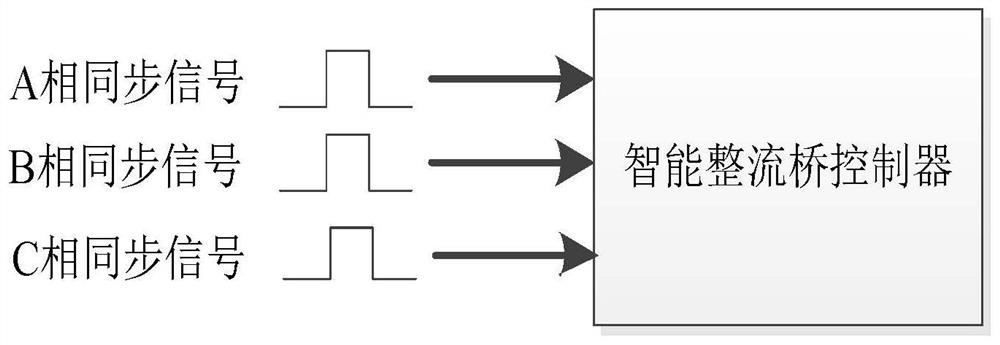

[0044] Determine the synchronous bias angle for each smart rectifier bridge through a small current test: only one smart rectifier bridge operates at a time, and use the phase A of this rectifier bridge to synchronously drive the trigger pulse. The anode voltage is set above 80V, and the small current tests of all smart rectifier bridges use the same amplitude anode voltage. At this time, the phase shift of the synchronous shaping circuit due to the startup threshold is basically the same as the phase shift during normal operation. Adjust the synchronous bias angle of smart rectifier bridge 1 so that the output waveform at 60° is consistent with the theory, and record the output voltage at this t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com