Badminton automatic gluing machine

A badminton, fully automatic technology, applied in the direction of pretreatment surface, liquid coating device on the surface, coating, etc., can solve the problems of inability to stack and place, unstable quality, large footprint, etc. Large size, reduced production cost, high space loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

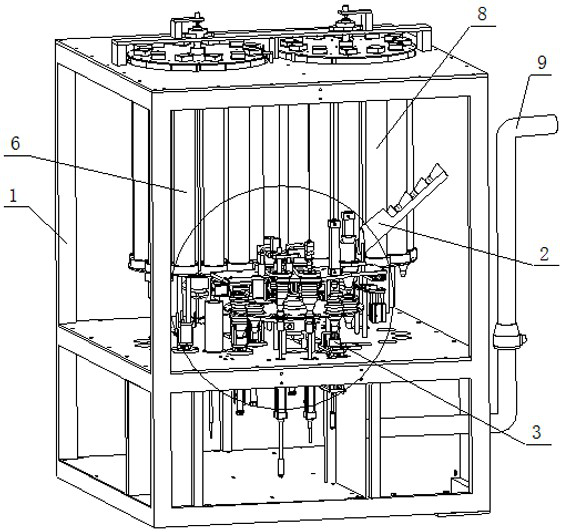

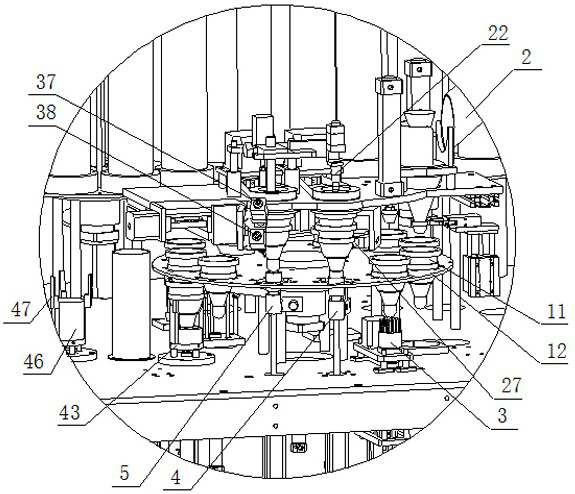

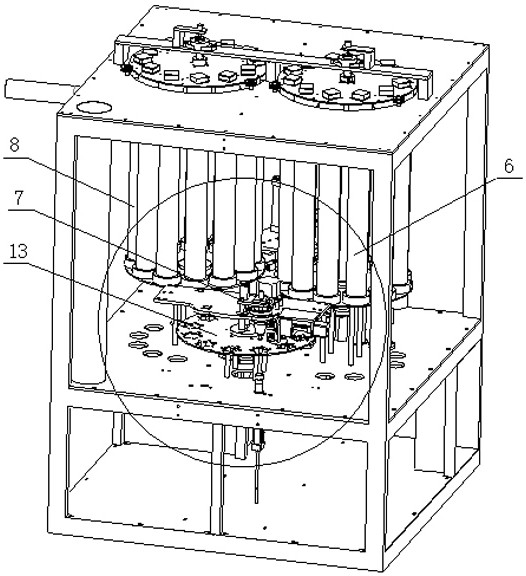

[0031] Attached below Figure 1-Figure 11 A further detailed description is given to the fully automatic gluing machine for shuttlecocks of the present invention:

[0032] The full-automatic badminton gluing machine of the present invention comprises a frame body 1, a ball sleeve 11, a controller, and a ball loading mechanism 2, a wire pushing mechanism 3, and a glue injection mechanism connected to the frame body 1 and coordinated and controlled by the controller. Mechanism 4, first station disc 12, second station disc 13, first rubber rolling mechanism 5, second rubber rolling mechanism 7, first drying mechanism 6, second drying mechanism 8 and delivery mechanism 9. Wherein, the shuttlecock 19 to be processed is always located in the ball sleeve 11 during the transmission process. The first station disc 12 and the second station disc 13 , the first glue rolling mechanism 5 and the second glue rolling mechanism 7 , the first drying mechanism 6 and the second drying mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com