An iron sheet fixed-distance slotter for building an iron sheet shed

A technology of iron sheet and fixed distance, which is applied in the direction of manufacturing tools, driving devices, metal processing machinery parts, etc., can solve the problems of low work efficiency and troublesome operation, and achieve the effect of high work efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

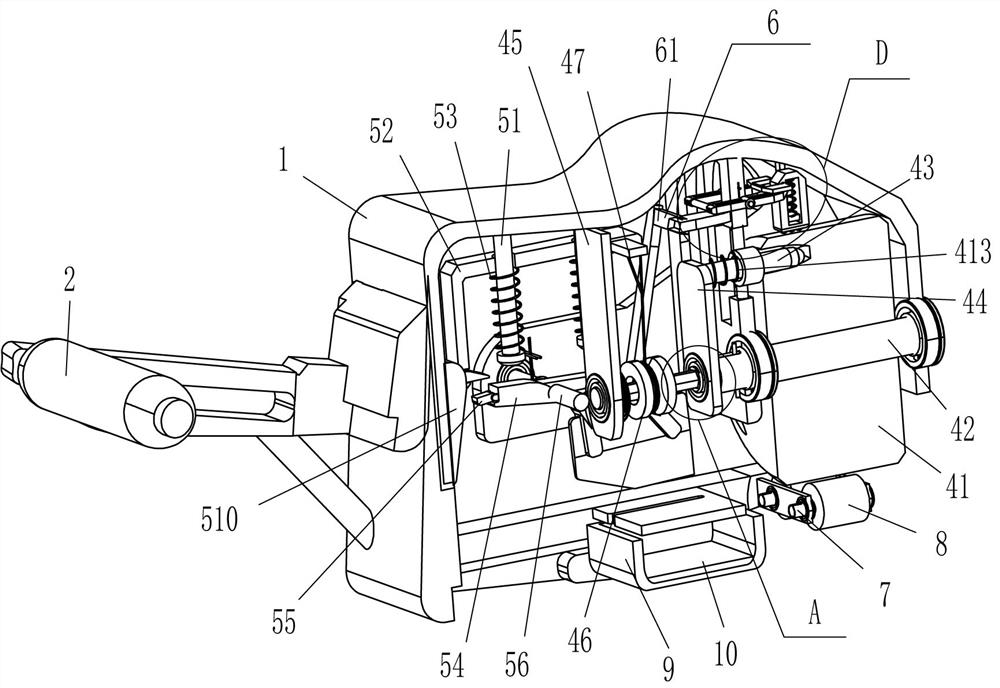

[0023] refer to Figure 1-Figure 6 , an iron sheet fixed-distance slotter for building an iron shed, comprising a casing 1, a handle 2, a multi-slot plate 3, a driving mechanism 4 and a cutting mechanism 5, the outer left side of the casing 1 is fixedly connected with the handle 2, the casing A multi-slot plate 3 is fixedly connected between the right side of the inner top of the body 1 and the right side of the inner front and rear sides, and a driving mechanism 4 is provided between the multi-slot plate 3 and the left side of the inner top of the housing 1, and the left side of the inner top of the housing 1 A cutting mechanism 5 is arranged between them, and the cutting mechanism 5 is fixedly connected with the driving mechanism 4 .

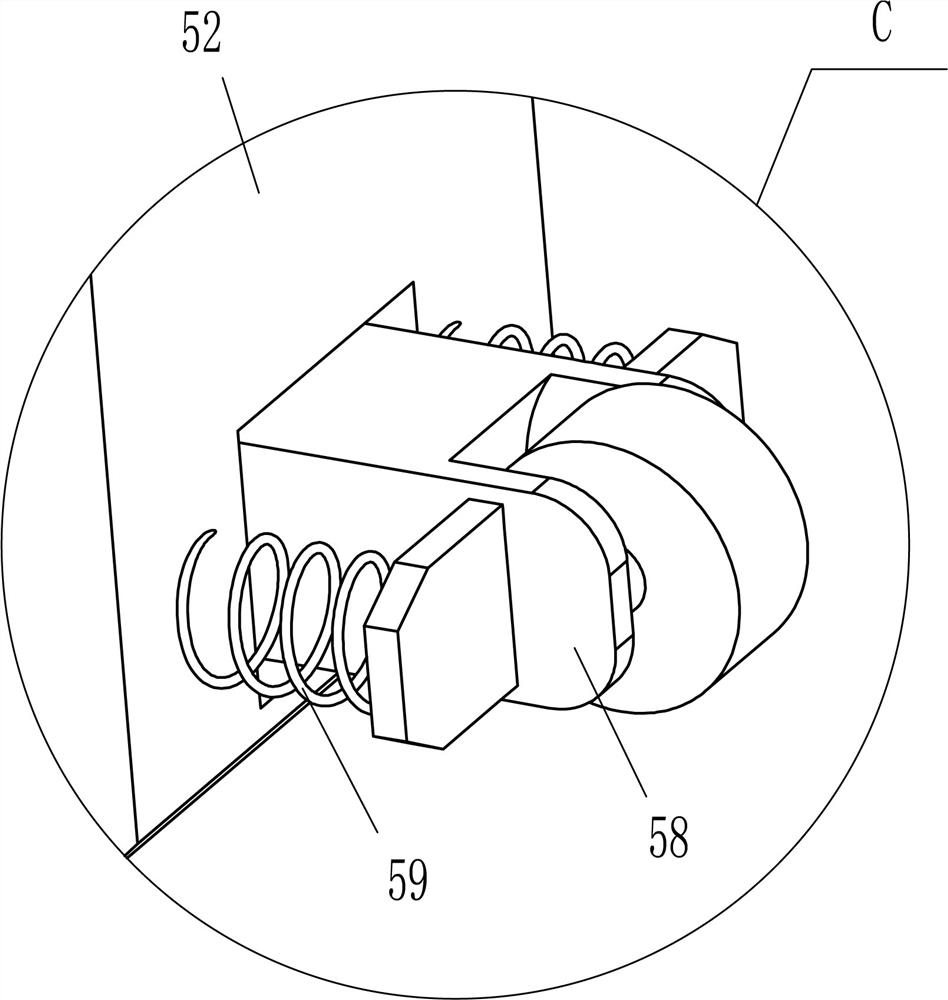

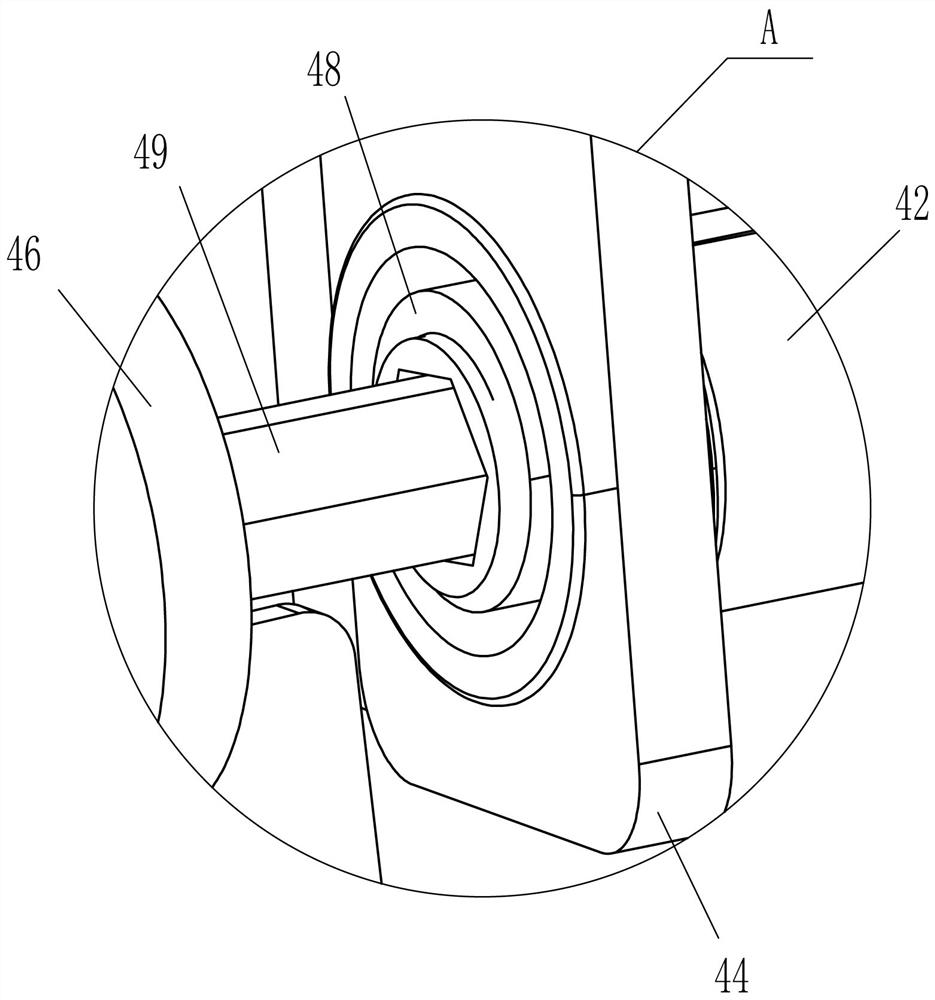

[0024] Drive mechanism 4 comprises cylinder 41, hollow rotating shaft 42, slide bar 43, fixed plate 44, riser 45, reel 46, backguy 47, hollow tube 48, hexagonal rod 49, contact rod 411, scroll spring 412 and Back-moving spring 413, a riser 45...

Embodiment 2

[0030] refer to figure 2 , image 3 and Figure 7 Compared with Embodiment 1, the main difference of this embodiment is that in this embodiment, a positioning mechanism 6 is also included, and the positioning mechanism 6 includes an n-shaped plate 61, a u-shaped bar 62, a return block 63, a swing frame 64, a second Two torsion springs 65 and the third spring 66, a u-shaped bar 62 is affixed in the middle of the top right side of the housing 1, and the sliding type in the middle part of the u-shaped bar 62 is provided with a return block 63, and the top of the return block 63 is connected to the u-shaped The third spring 66 is connected between the inner bottom of the rod 62, and a swing frame 64 is hinged in the middle of the upper part of the multi-slot plate 3. The right end of the swing frame 64 contacts and cooperates with the return block 63. The second torsion spring 65 is fixedly connected with an n-type plate 61 between the front and rear sides cutter 54 top right s...

Embodiment 3

[0033] refer to figure 1 and figure 2 , the main difference between this embodiment and embodiment 1 and embodiment 2 is that in this embodiment, there are also rollers 7 and guide cylinders 8, and the rotating type is evenly spaced between the lower right side of the front and rear sides of the housing 1. A roller shaft 7 is connected, and a guide cylinder 8 is fixedly connected to the roller shaft 7 .

[0034] It also includes a collection frame 9 and a permanent magnet 10 , a collection frame 9 that can collect iron filings is slid between the lower parts of the housing 1 , and the bottom of the collection frame 9 is fixed with a permanent magnet 10 .

[0035] When the housing 1 is placed on the edge of the iron sheet, the iron sheet is still in contact with the guide cylinder 8, and then the operator pulls the handle 2 to move the housing 1 on the iron sheet, and the guide cylinder 8 rolls on the iron sheet. In this way, the device can be moved more smoothly on the iron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com