Circuit board welding machine for intelligent manufacturing

An intelligent manufacturing and welding machine technology, applied in welding equipment, manufacturing tools, auxiliary welding equipment, etc., can solve the problems of poor positioning accuracy, inability to weld, and difficult to guarantee welding quality, to ensure a sense of adaptability and free adjustment, Effect that is convenient for angle and position adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

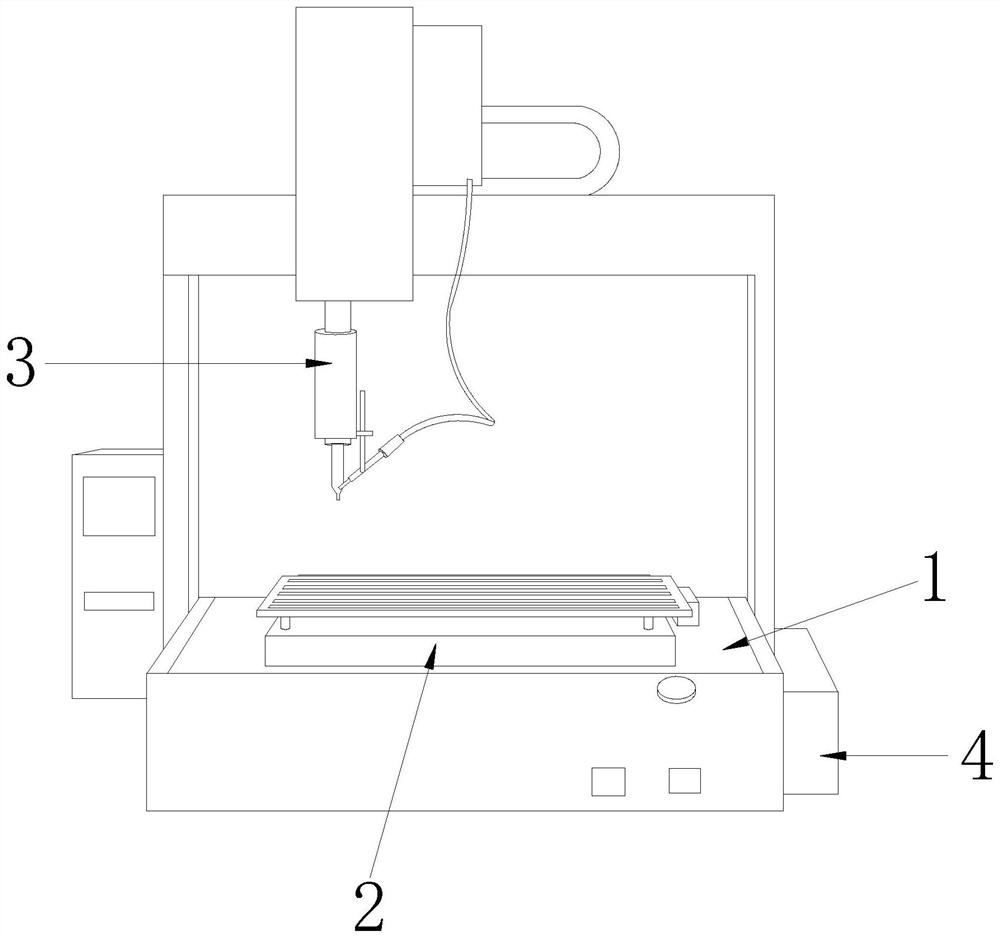

[0031] as Figure 1-Figure 4 As shown, the present invention provides a technical solution for intelligent manufacturing circuit board welding machine:

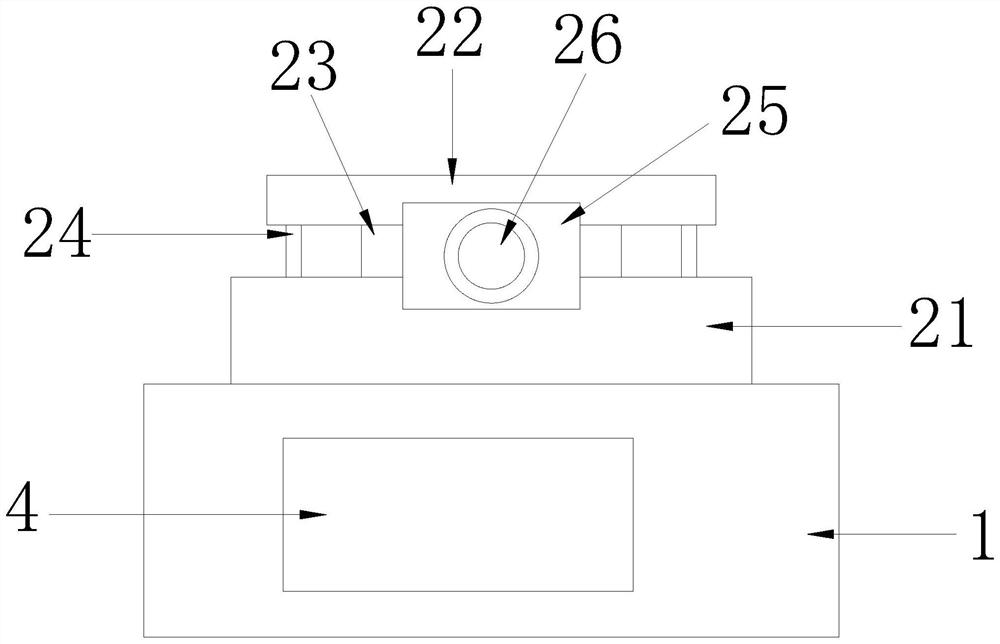

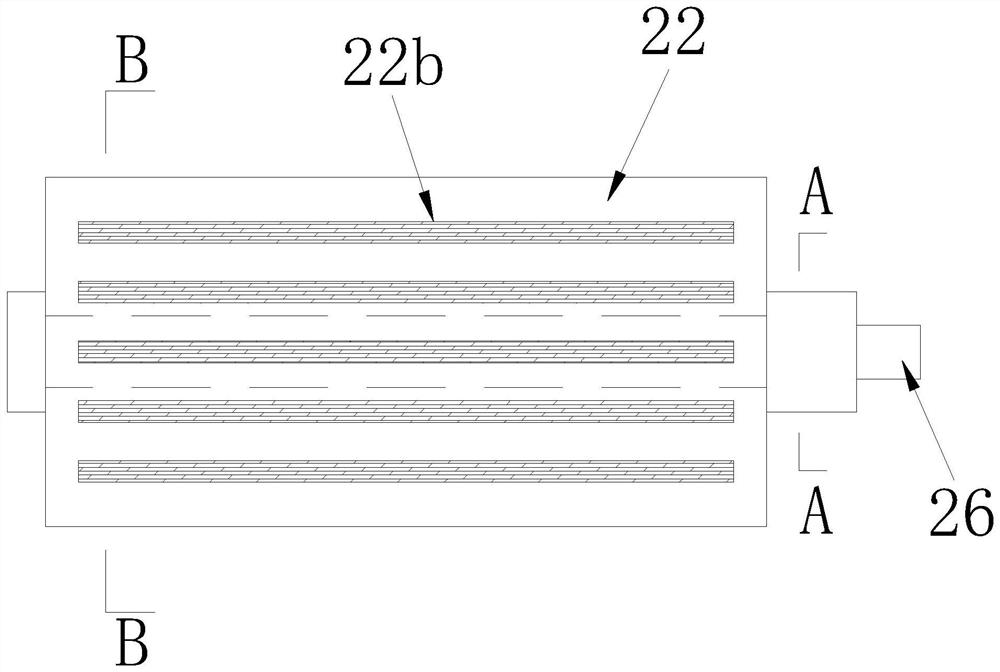

[0032] Intelligent manufacturing circuit board welding machine, the structure of which includes welding machine body 1, the workbench located on the upper surface of the welding machine body 1, the weldment working with the workbench 2 and located above it 3 and the negative press with the workbench 2 4, the workbench 2 includes a rectangular frame 21, the movable frame plate located above the rectangular frame 21 22, the ventilation pipe for the moving frame plate 22 and the rectangular frame 21, the adjustment rod 24 with two and for the up and down movement of the moving frame plate 22, The limiting shaft frame 25 is located on the surface of the rectangular frame 21 and the limiting member 26 is axially oriented through the left and right sides of the movable frame plate 22 and cooperates with the limiting frame 25.

[0033] S...

Embodiment 2

[0038] as Figure 1-Figure 5 As shown, the present invention provides a technical solution for intelligent manufacturing circuit board welding machine:

[0039] as Figure 1-Figure 5As shown, a kind of intelligent manufacturing circuit board welding machine, the middle of the limit shaft frame 25 is provided with a circular groove hole 251, located in the inner wall of the circular groove hole 251 sealing ring 252, a semi-arc structure installed in the inner wall of the sealing ring 252 limit arc plate 253 and the limit arc plate 253 for concentric circle structure and relatively symmetrical installation of the gear bar 254, for the free adjustment of the moving frame plate 22 with the limit 26, thereby expanding the position angle adjustment required in the welding process.

[0040] as Figure 1-Figure 5 As shown, the sealing ring 252 is a flexible magnetic material for achieving resistance when the limit 26 is adjusted, thereby achieving a stable fit when increasing the adjustment....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com