Plastic forming machine and method for operating same

A molding machine and plastic technology, applied in the field of operating plastic molding machines, can solve the problems of different unloading characteristics of hydraulic pressure accumulators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

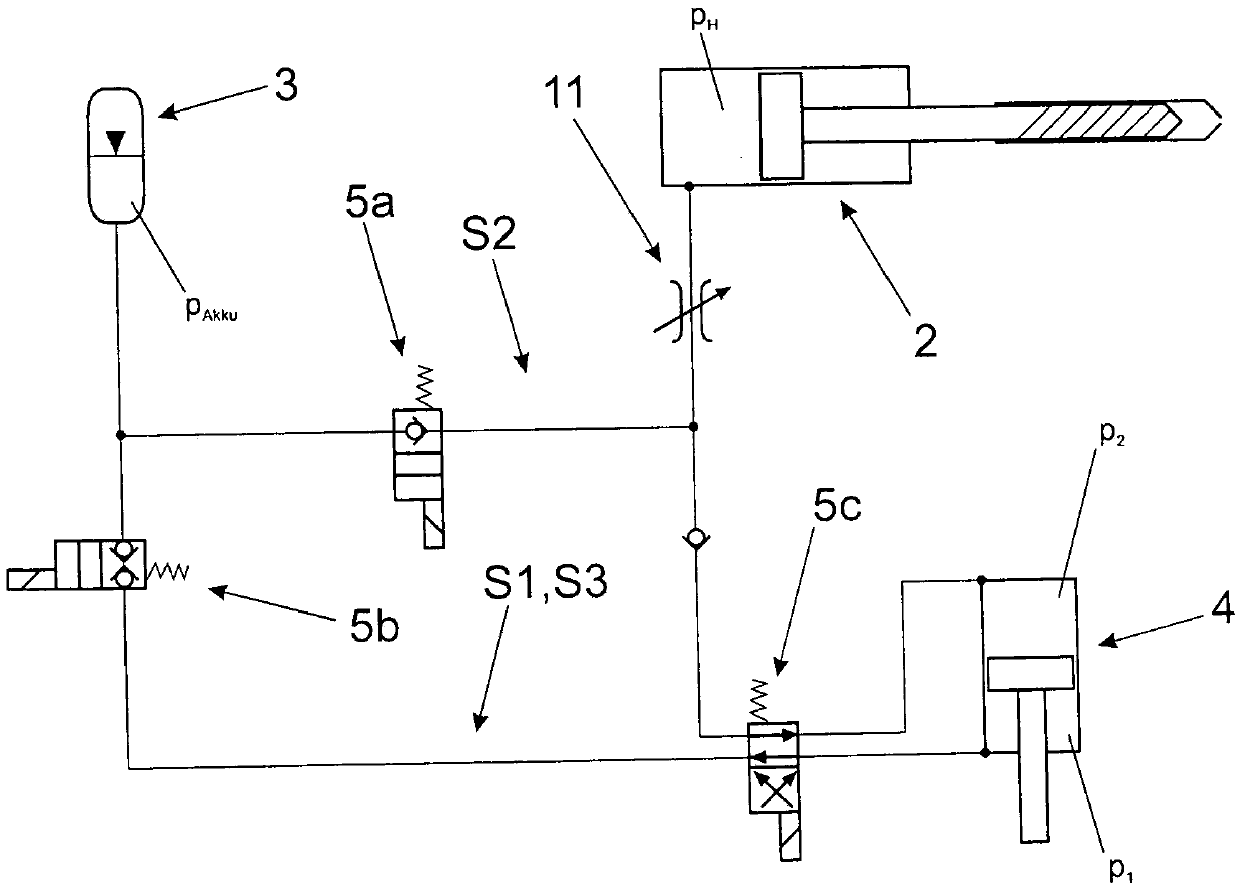

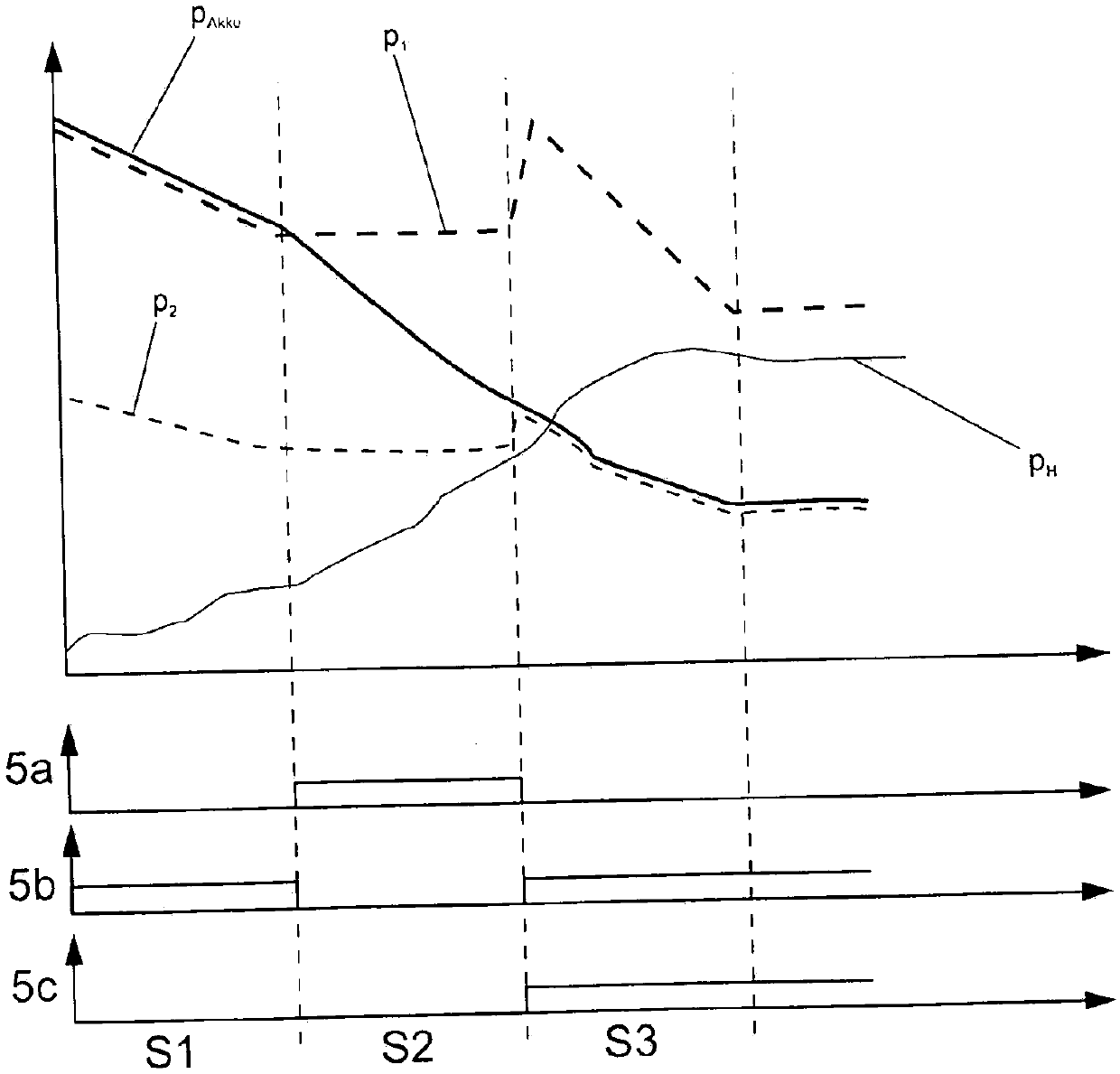

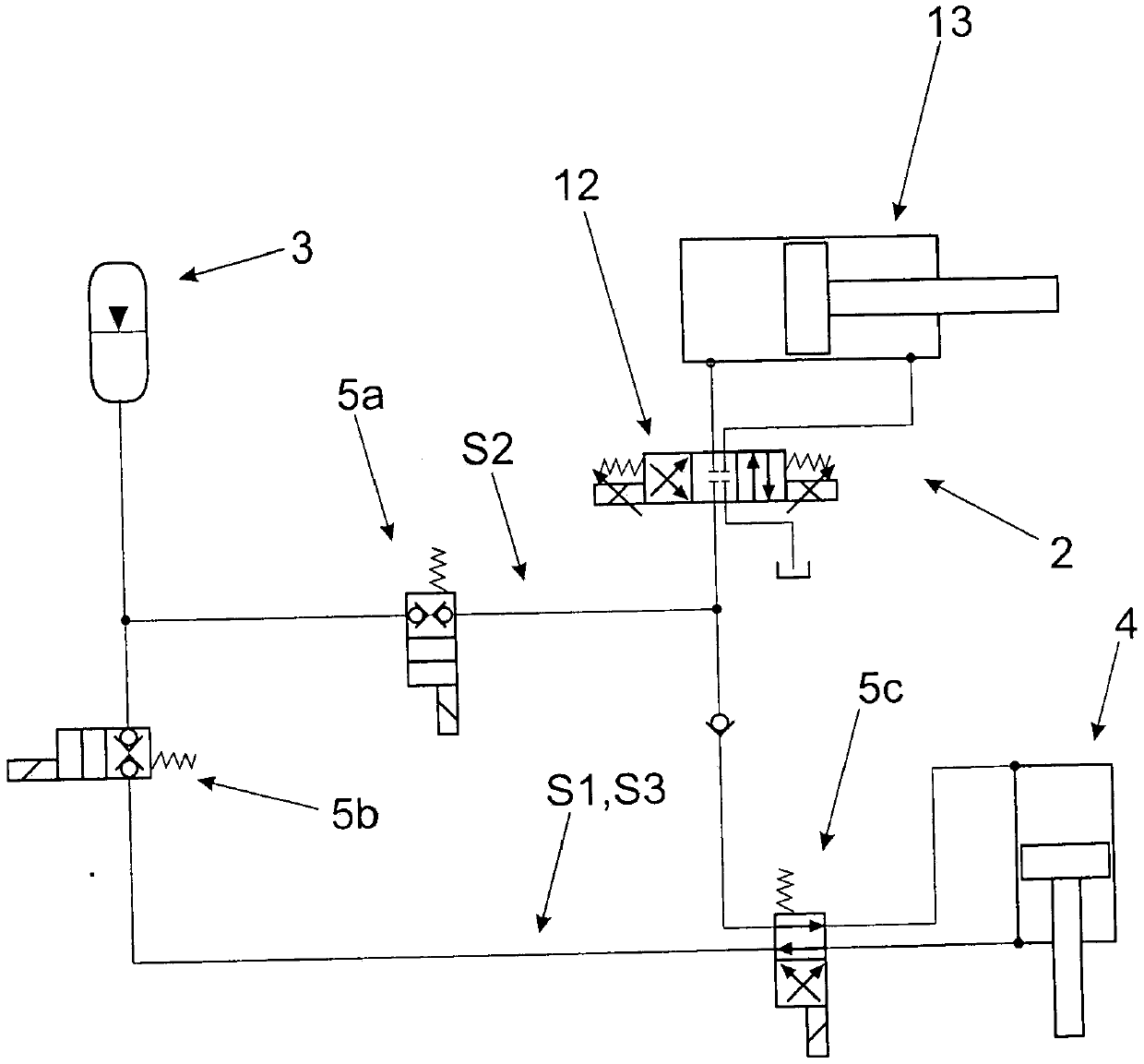

[0039] Figure 1a Firstly, a first exemplary embodiment of a hydraulic circuit for operating a plastics molding machine as an injection cylinder of a consumer 2 is shown. Firstly, the pressure accumulator 3 is shown, which utilizes the accumulated pressure p Akku load. Furthermore, there is a pressure transducer 4 which is implemented via a circuit with a plurality of switching valves 5a, 5b, 5c.

[0040] The consumer 2 is supplied by the line, wherein a volume flow regulating valve 11 is also provided for regulating the process, for example regulating the injection speed. The three stages S1 , S2 , S3 of pressurization and depressurization are realized by said switching valves 5 a , 5 b , 5 c. The first stage S1 is activated when the boost valve 5b is switched on. Therefore, the stored accumulated pressure p at the pressure accumulator 3 Akku The lower hydraulic fluid is led into the lower chamber of the pressure transducer 4 in the figure. In the pressure transducer 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com