Aluminum-based graphene-based composite material as well as preparation method and application thereof

A composite material and graphene technology, applied in the field of material processing and preparation, can solve the problems of thermodynamic instability affecting the flatness of the outer covering material, difficult to guarantee the reliability of the material, complex interface shapes such as wrinkles, etc., and is suitable for automatic mass production. , process environmental protection, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 proposes a kind of composite material based on aluminum-based graphene, and its preparation method comprises the steps:

[0023] (1) Mix and stir the aluminum-based skeleton graphene composite material and the polyol to obtain a reaction solution; the mass fraction of the aluminum-based skeleton graphene composite material is 1%.

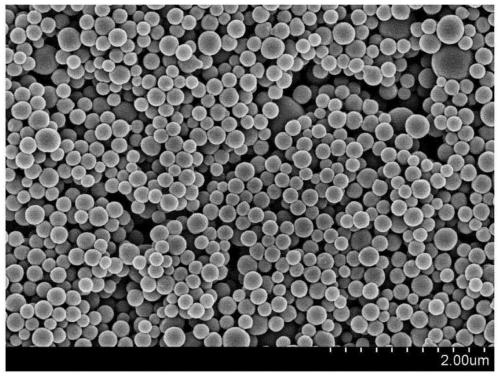

[0024] (2) The polyester, auxiliary agent, crosslinking agent and catalyst are mixed according to the weight ratio of 1:1.2:0.3:1 and then blended with the reaction solution obtained in the step (1) at a temperature of 64.8°C for 30s, Obtain isocyanate materials with nanoscale microphase chemically bonded network structure, such as figure 1 shown; and the mixture of the polyester, auxiliary agent, crosslinking agent and catalyst in the preset ratio accounts for 2% of the mass of the reaction solution obtained in the step (1).

[0025] (3) Mix the isocyanate material obtained in step (2) with the reaction solution obtained in ste...

Embodiment 2

[0027] Embodiment 2 proposes a kind of composite material based on aluminum-based graphene, and its preparation method comprises the steps:

[0028] (1) Mix and stir the aluminum-based skeleton graphene composite material and polyol to obtain a reaction solution; the mass fraction of the aluminum-based skeleton graphene composite material is 3%.

[0029] (2) The polyester, auxiliary agent, crosslinking agent and catalyst are mixed according to the weight ratio of 1:0.8:0.8:0.1 and then blended with the reaction solution obtained in the step (1) at a temperature of 65.2°C for 15s, Obtain an isocyanate material with a network structure of nano-scale micro-phase chemical combination; and the mixture of the polyester, auxiliary agent, crosslinking agent and catalyst in the preset ratio accounts for 10% of the quality of the reaction solution obtained in the step (1) 8%.

[0030] (3) Mix the isocyanate material obtained in step (2) with the reaction solution obtained in step (1) a...

Embodiment 3

[0032] Embodiment 3 proposes a kind of composite material based on aluminum-based graphene, and its preparation method comprises the steps:

[0033] (1) Mix and stir the aluminum-based skeleton graphene composite material and the polyol to obtain a reaction solution; the mass fraction of the aluminum-based skeleton graphene composite material is 2%.

[0034] (2) After mixing the polyester, auxiliary agent, crosslinking agent and catalyst in a weight ratio of 2:2:1:1, they are blended with the reaction solution obtained in step S101 at a temperature of 65°C for 18s to obtain The isocyanate material of the network structure of nanoscale microphase chemical combination; and the mixture of the polyester, auxiliary agent, crosslinking agent and catalyst of the preset ratio accounts for 5% of the mass of the reaction solution obtained in the step (1) .

[0035] (3) Mix the isocyanate material obtained in step (2) with the reaction solution obtained in step (1) at a temperature of 6...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap