Wheel hub for direct driving type wind turbine generator and direct driving type wind turbine generator

A wind turbine, direct-drive technology, applied in the assembly of wind turbines, wind turbines, wind energy power generation, etc., can solve the problems of large amount of steel, poor process practicability, and uncompact structure, and can simplify the number of parts and improve the The effect of product reliability and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

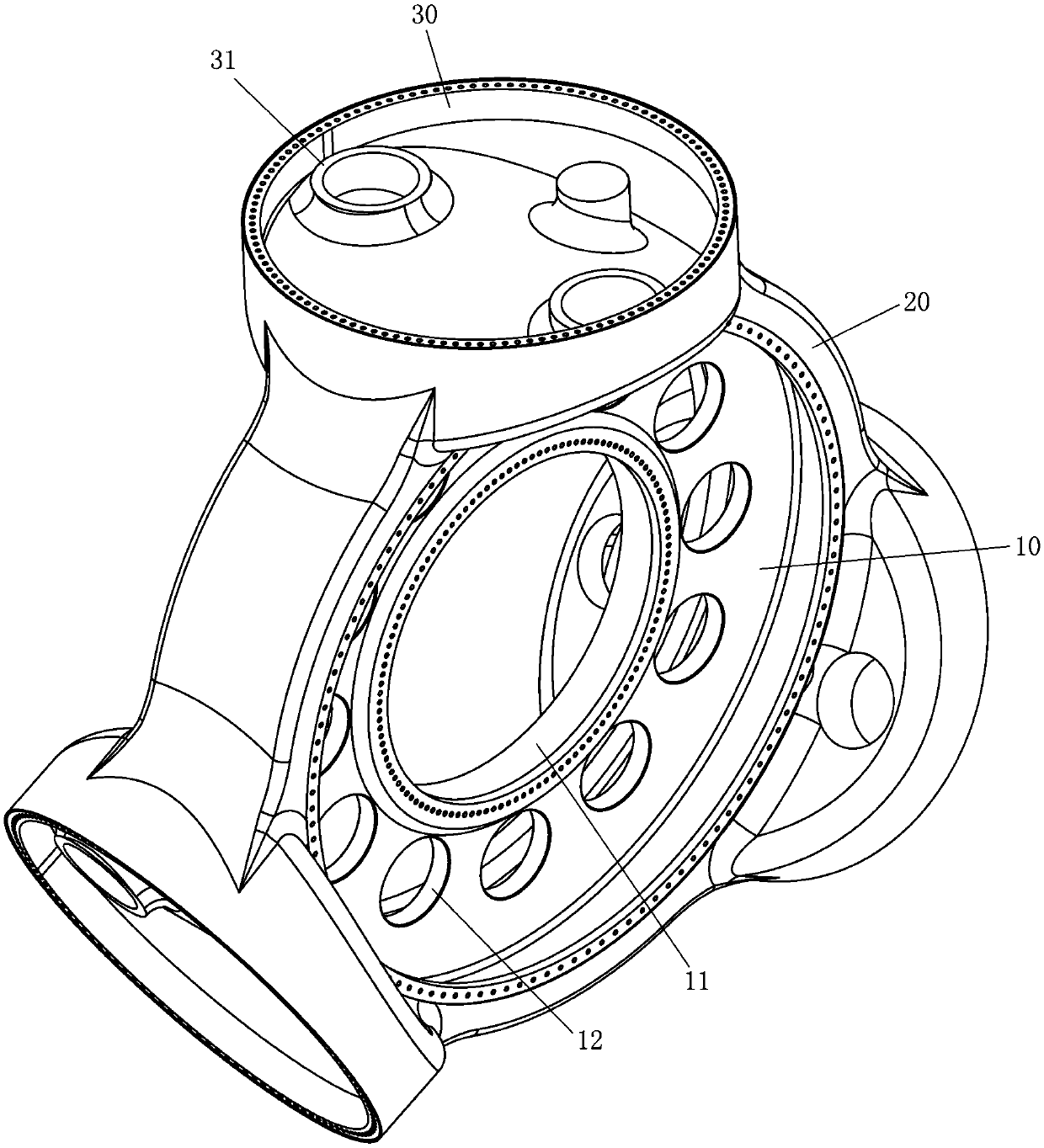

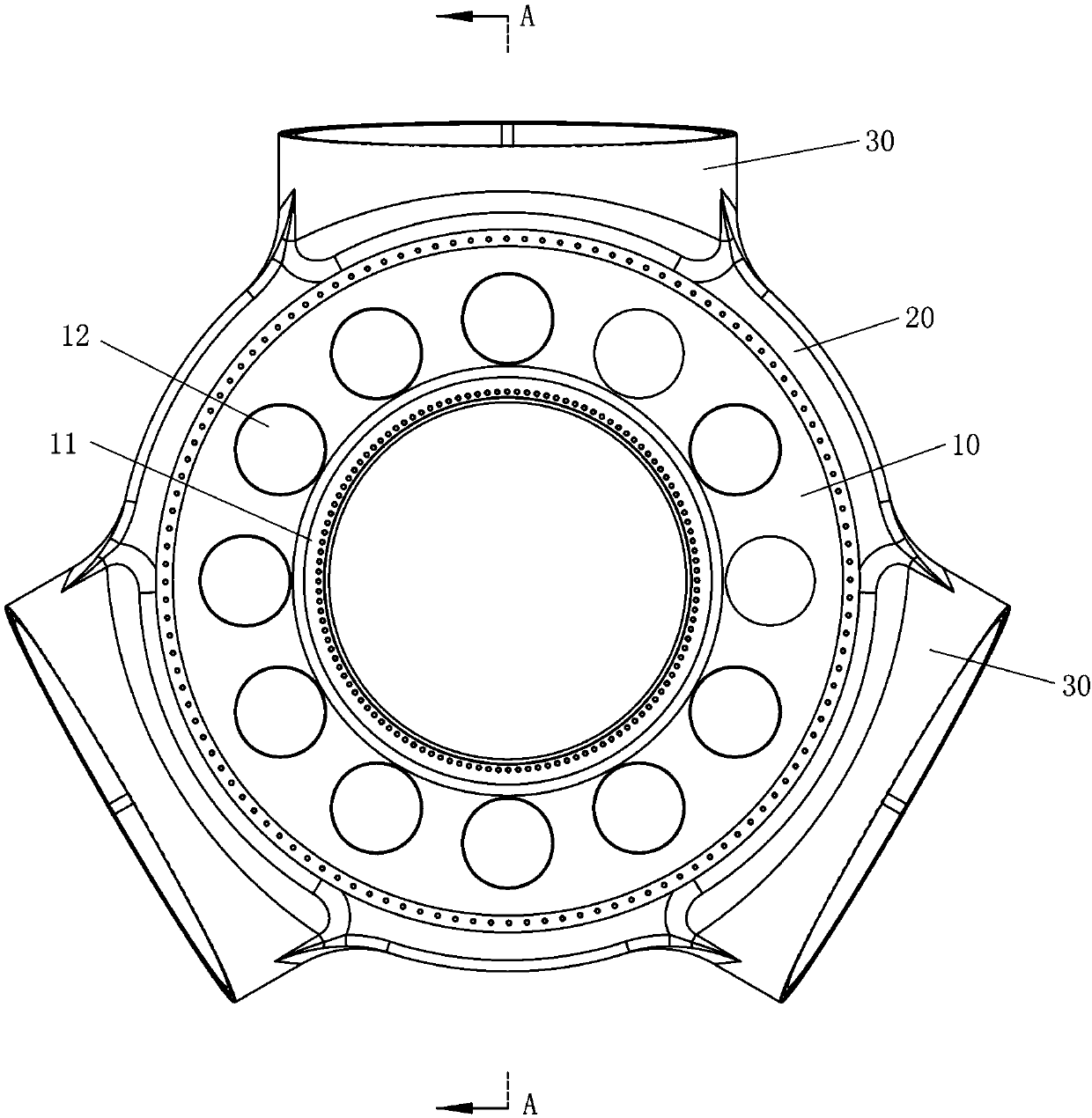

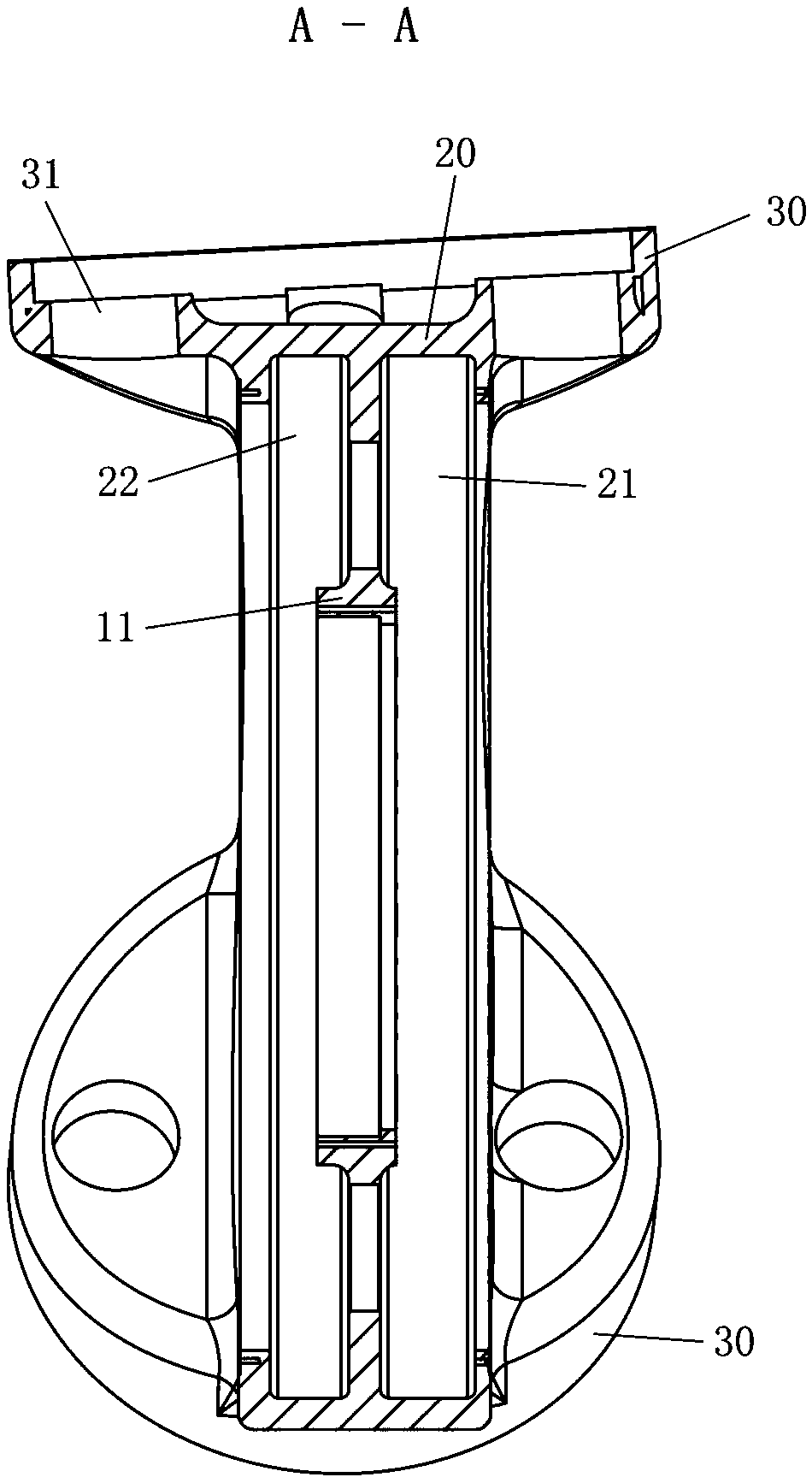

[0024] The embodiment of the present invention proposes a technical proposal of integrating the wheel hub and the generator housing. By forming the generator accommodating cavity on the hub, the hub is used to form the outer casing of the generator, and the rotor of the generator is installed on the outer casing of the generator formed by the hub. By building the generator into the hub, the number of connections and the volume, weight and cost of the generator set are greatly reduced. Hereinafter, embodiments according to the present invention will be described in detail with reference to the accompanying drawings.

[0025] Such as Figure 1-3 As shown, the wheel hub 100 according to the embodiment of the present invention is generally disc-shaped, including a disc-shaped spoke part 10, and an outer flange 20 is formed on the outer circumference of the spoke part 10, and the outer flange 20 is formed along the axial direction of the wheel hub 100. Extend a predetermined leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com