Pneumatic piston push type lift pump

A push-type, lifting pump technology, applied in the direction of non-volume pumps, pumps, jet pumps, etc., can solve the problems of low efficiency of air lift pumps, achieve the effect of promoting momentum exchange efficiency, enhancing drag force, and improving work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

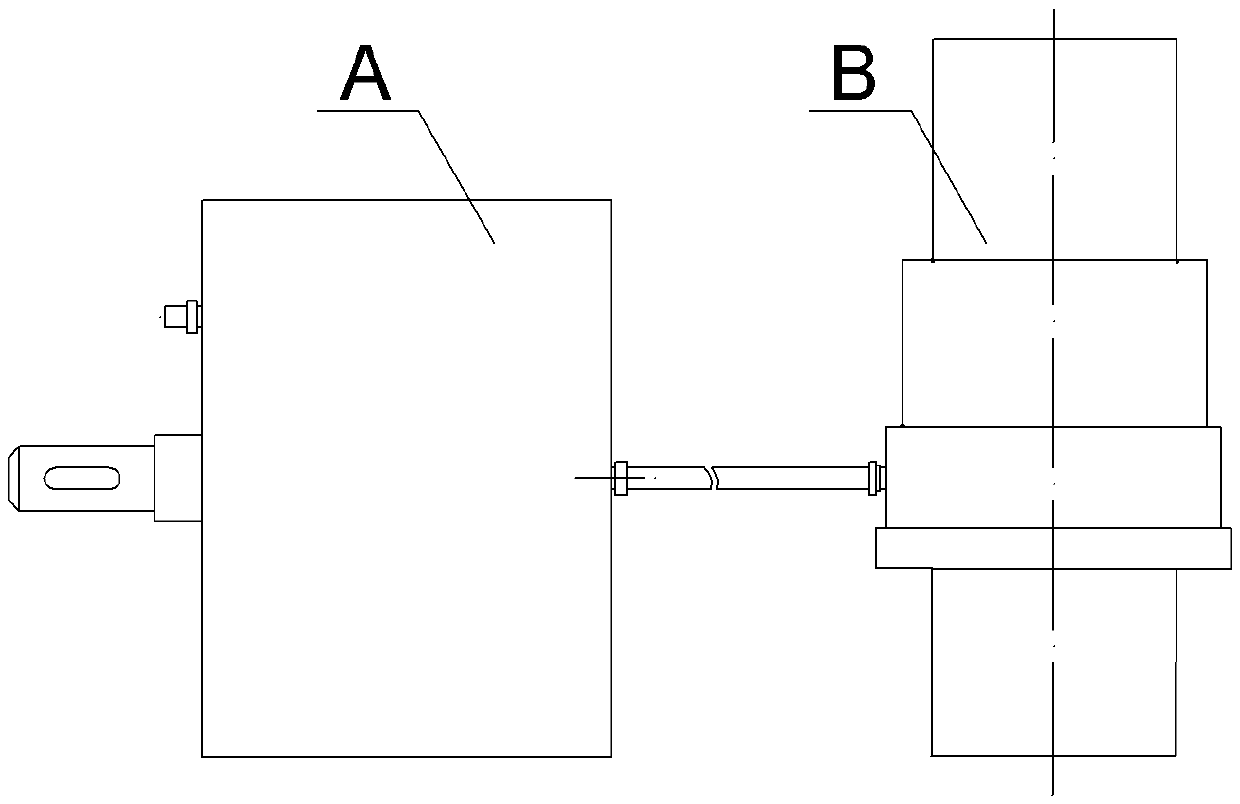

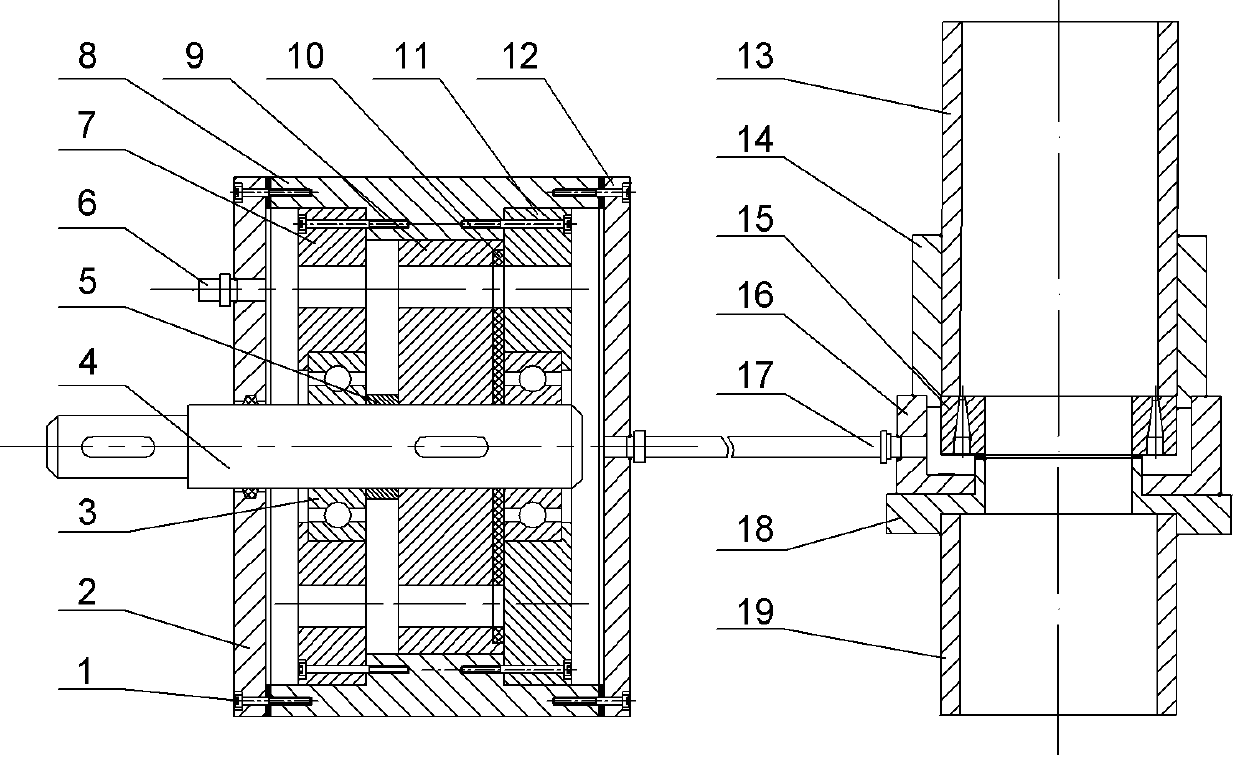

[0035] Assembly method of the present invention: as figure 1 As shown, the pneumatic piston-driven lift pump consists of an airflow pulse generating device (A) and an airflow injector (B).

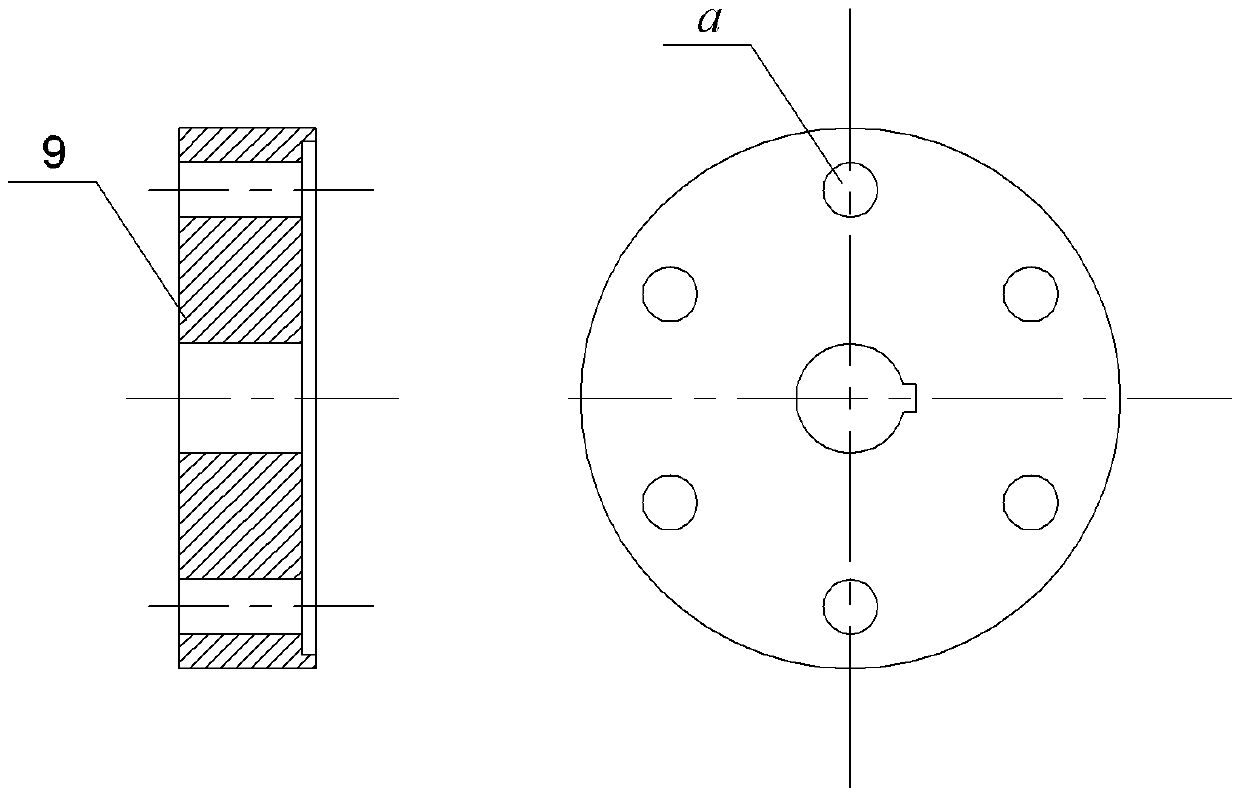

[0036] In the pulsed air flow generator (A), the rectifier disc (7) is closely attached to the outer shell (8) through bolts; the air distribution static disc is tightly connected to the outer shell (8) through bolts; Connected with the rotating shaft (4) through a flat key, it can rotate together with the rotating shaft; in order to reduce the gas leakage between the gas distribution disc and the gas distribution static disc, a sealing disc is embedded in the pit on the right side of the pneumatic disc, and the sealing disc has the same The exhaust hole structure is the same as that of the pneumatic disc, and its material is polytetrafluoroethylene; the center holes of the rectifier disc (7) and the static disc (11) are respectively equipped with rolling bearings (3), and the inner rings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com