A cross-flattened multi-longitudinal vortex flow tube and its reactor

A reactor and longitudinal technology, which is applied in the field of cross-flattened multi-longitudinal vortex flow tubes and their reactors, can solve the problems of difficulty in manufacturing quality assurance and supervision, affecting the overall reaction efficiency, clogging, etc., to ensure long-term stable operation. , safe, reliable and efficient operation, the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

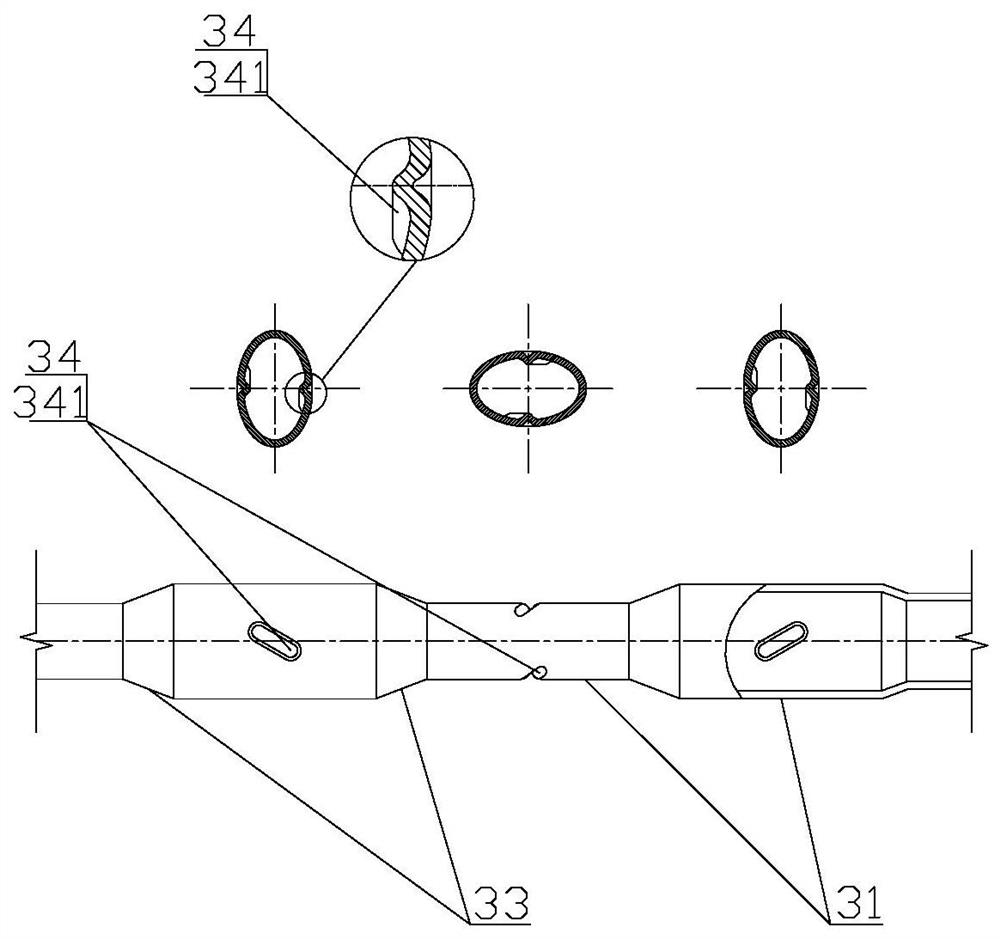

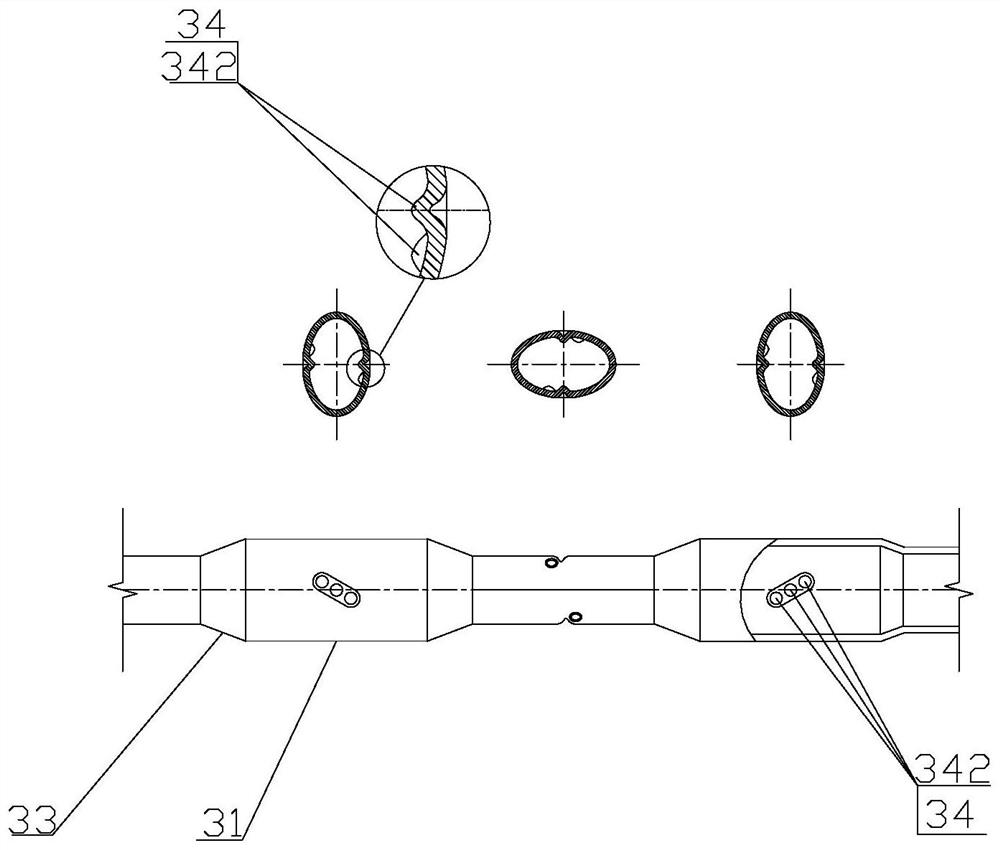

[0064] In some embodiments, the reactor 100 is used as a wet oxidation reactor 100 in the organic solid waste wet oxidation treatment and disposal technology, and it is necessary to add main reaction materials and auxiliary reaction materials to make the materials fully react; as Figure 8-Figure 17 As shown, the reactor 100 includes a shell 1, a support member 2, a plurality of cross-flattened multi-longitudinal vortex flow tubes 3, a main reaction material inlet and outlet connecting pipe 44, an auxiliary reaction material inlet and outlet connecting pipe 5, and connecting pieces between reaction tubes 6, and mixer 7.

[0065]Specifically, the support member 2 is arranged in the shell 1, and a plurality of cross-flattened multi-longitudinal vortex flow tubes 3 are arranged on the support member 2, and the plurality of cross-squashed multi-longitudinal vortex flow tubes 3 pass through the connector 6 between the reaction tubes They are connected successively, so that the mate...

Embodiment 2

[0076] In some embodiments, the reactor 100 is used as a thermal hydrolysis reactor 100 in the thermal hydrolysis treatment and disposal technology of organic solid waste, so as to avoid problems such as eddy current dead zone and uneven reaction in traditional tank-type hydrothermal reaction devices ;Such as Figure 18 As shown, the reactor 100 includes a shell 1, a support 2 and the above-mentioned multiple cross-flattened multi-longitudinal vortex tubes 3; wherein, the support 2 is arranged in the shell 1, and a plurality of the cross The flattened multi-longitudinal vortex tubes 3 are arranged on the support member 2, and the adjacent intersected flattened multi-longitudinal vortex tubes 3 are connected and communicated through the connecting piece 6 between the reaction tubes, so that multiple crossed The flattened multi-vertical vortex flow tubes 3 are continuously connected to form a pipeline for material reaction; the multiple cross-squashed multi-longitudinal vortex f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com