Automatic feeding mechanism for clamp body machining

A technology of feeding mechanism and pliers, which is applied in the direction of metal processing, conveyor objects, metal processing equipment, etc., can solve the problems of large manpower and consumption, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

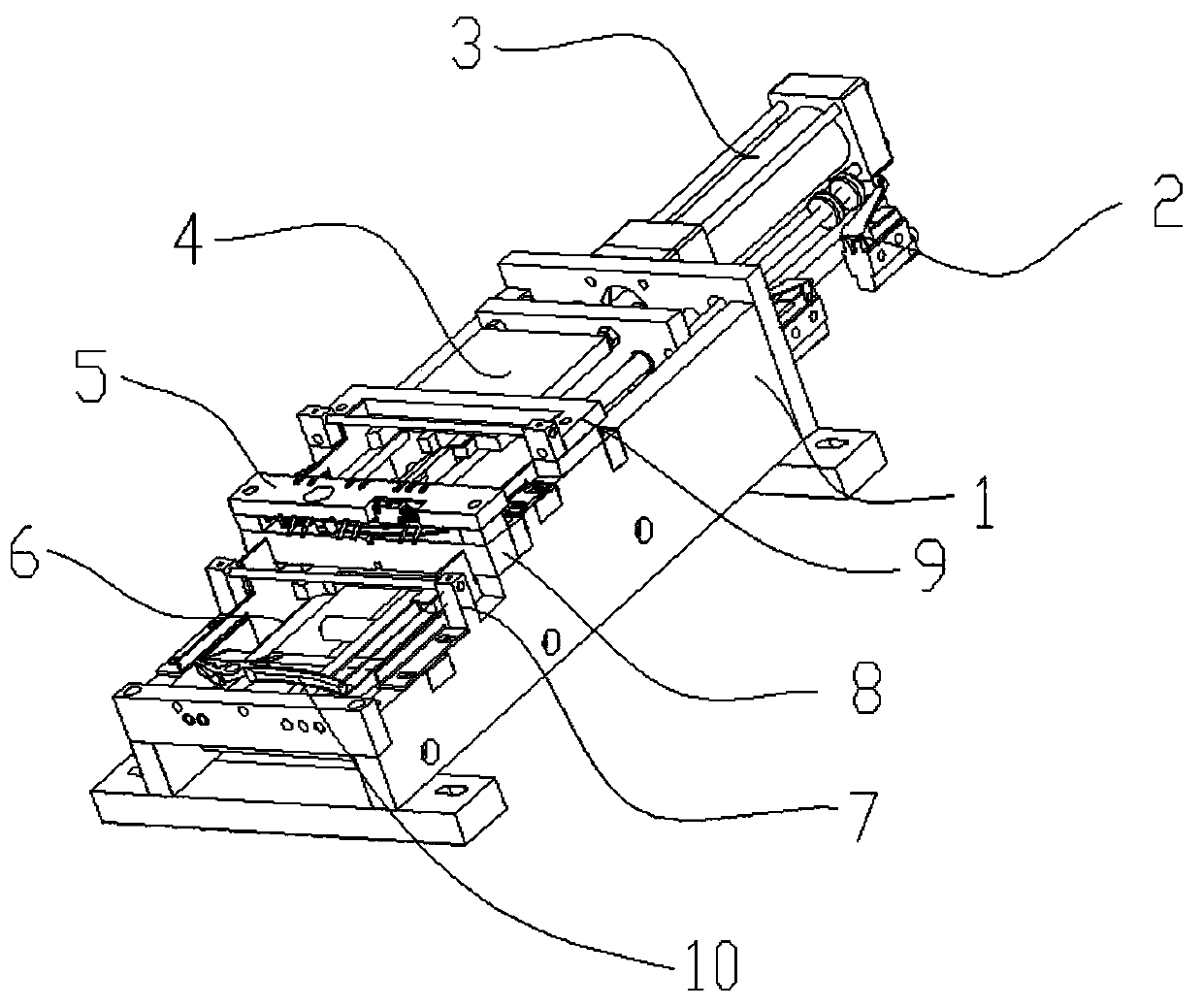

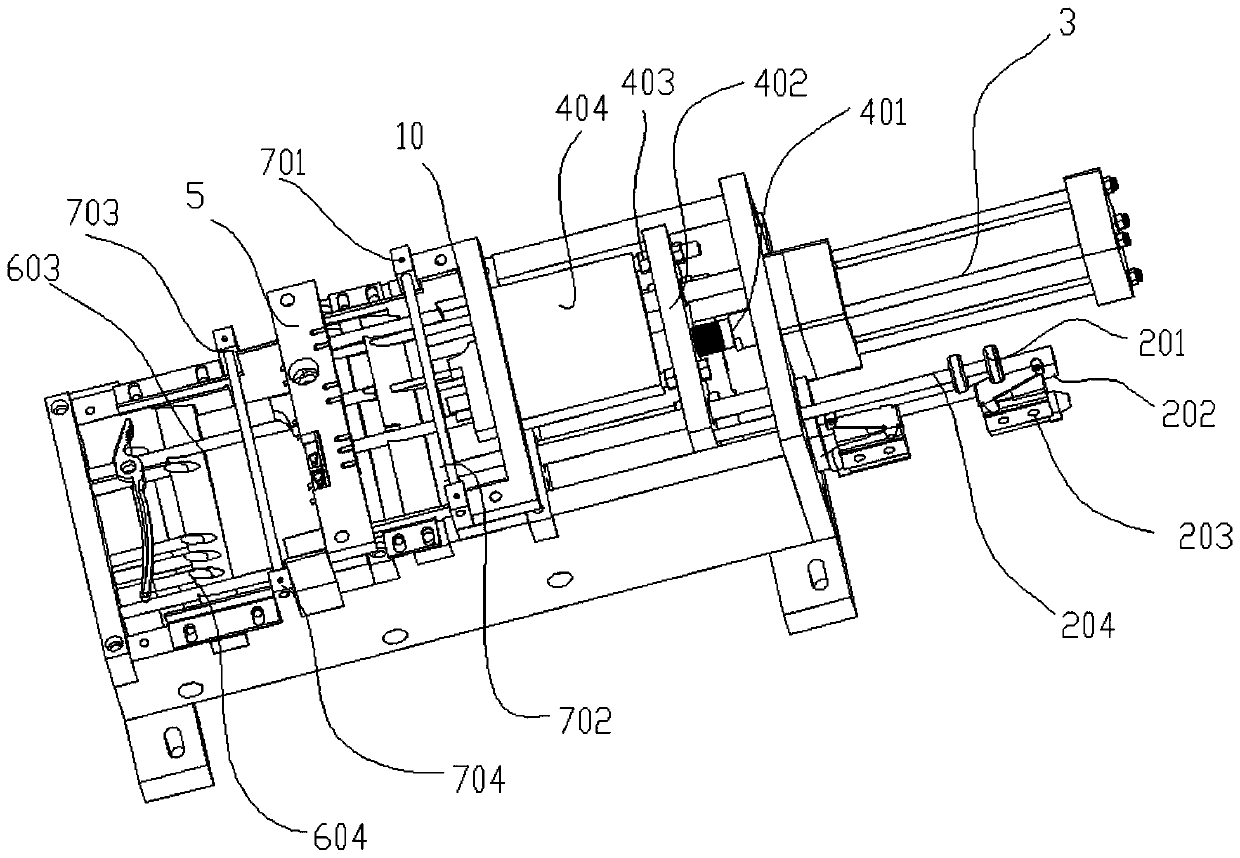

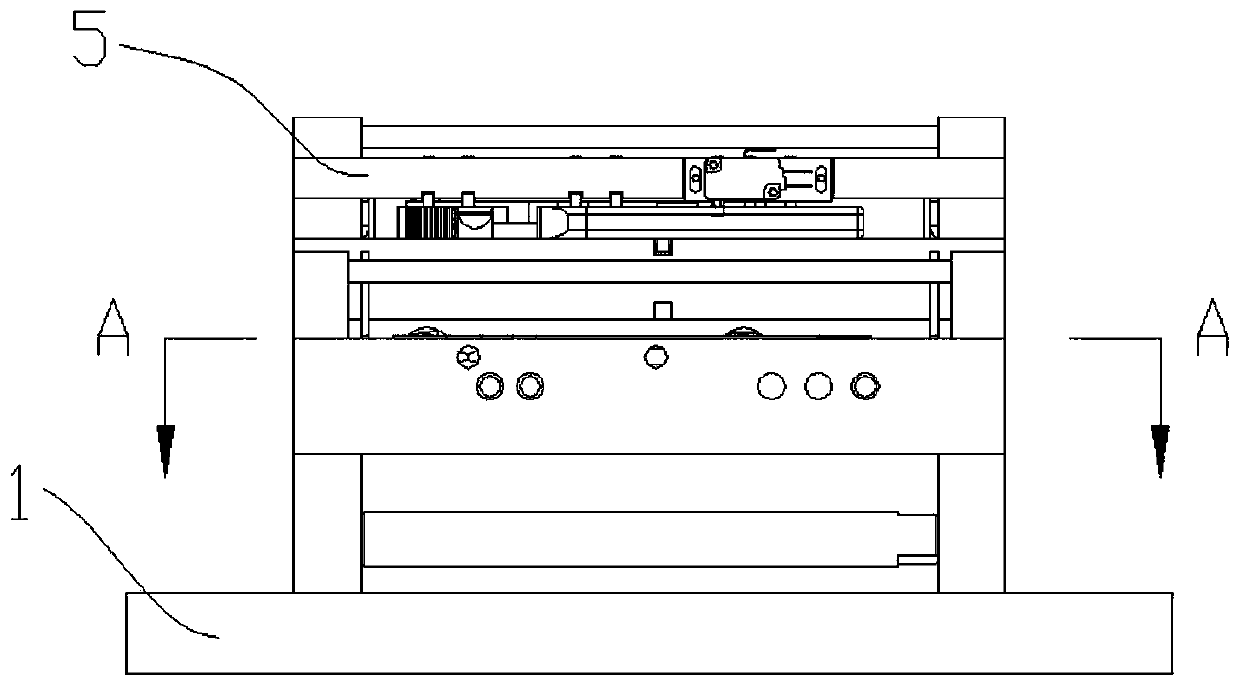

[0040] Such as Figure 1-Figure 10 Shown, the concrete structure of the present invention is:

[0041] An automatic feeding mechanism for pliers body processing, including a frame 1, a travel switch 2, a driving device 3, a pushing device 4, a processing trigger device 5, a guiding device 6, a height limiting device 7 and an auxiliary supporting device 8; The device 3 is fixed on the rear wall of the frame 1 and connected with the pusher device 4. An auxiliary support device 8 is fixed in the middle of the frame 1. The auxiliary support device 8 mainly provides support for the construction of other co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com