Electric automatization machining platform

A technology of electrical automation and processing platform, which is applied in the direction of workbench, manufacturing tools, workpiece clamping device, etc., which can solve the problems of inconvenient clamping and processing operations of products, and achieve the prevention of slider rotation, prevention of unstable fixation, and easy handling out effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

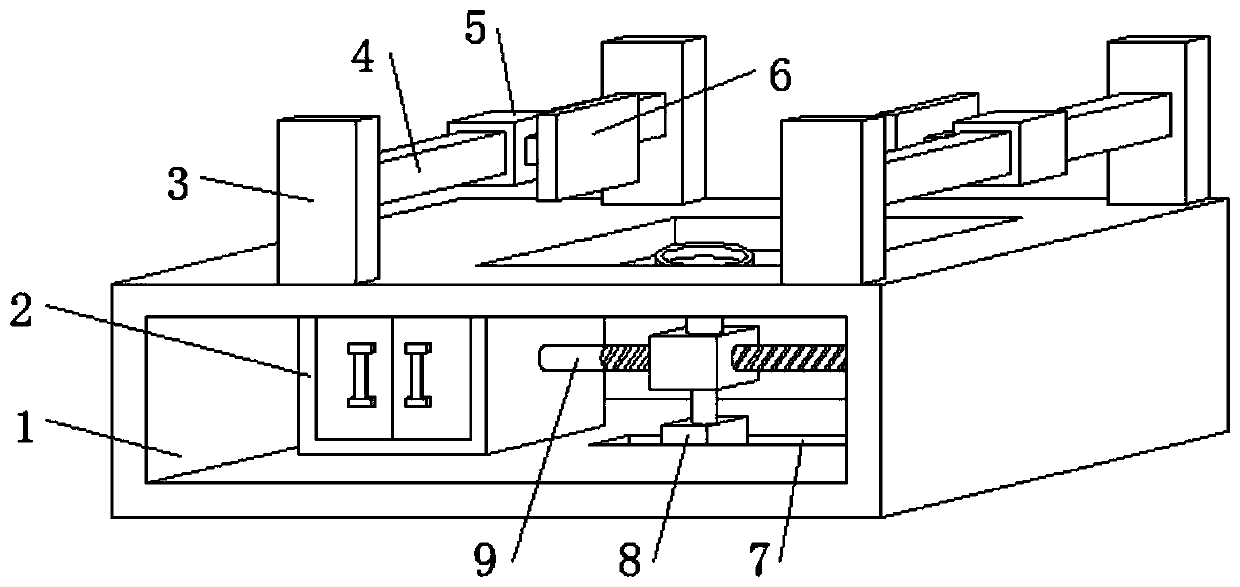

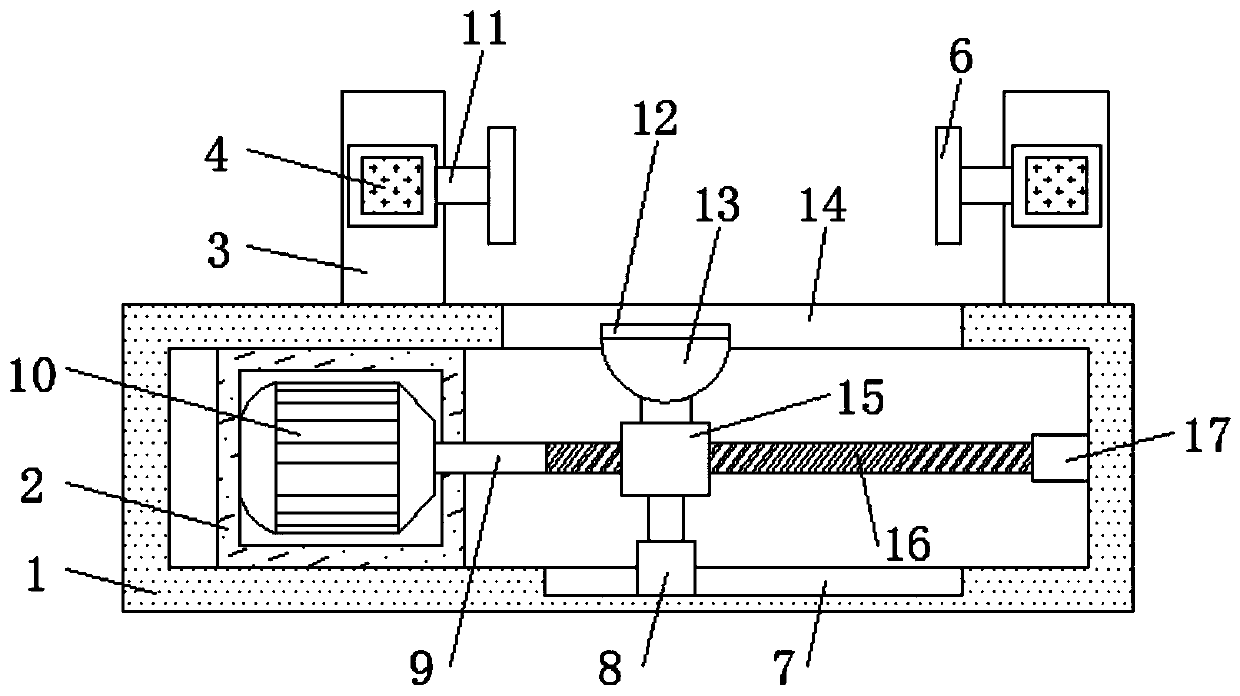

[0024] refer to Figure 1-2 , an electrical automation processing platform, comprising a rectangular frame 1, a motor box 2 is fixed on one side of the bottom inner wall of the rectangular frame 1 by bolts, a motor 10 is fixed on one side of the inner wall of the motor box 2 by bolts, and one end of the output shaft of the motor 10 The key is connected with a transmission shaft 9, and one end of the transmission shaft 9 is located outside the motor box 2, and one end of the transmission shaft 9 is keyed with a screw rod 16, and the inner wall of the side of the rectangular frame 1 away from the motor box 2 is fixed with a bearing 17, and the screw rod One end of 16 is rotatably inserted on the circumferential inner wall of bearing 17, and the circumferential outer wall of screw rod 16 is slidably connected with slide block 15, and the top outer wall of slide block 15 is fixed with electromagnetic chuck 13 by bolts.

[0025] In the present invention, the magnetically conductive...

Embodiment 2

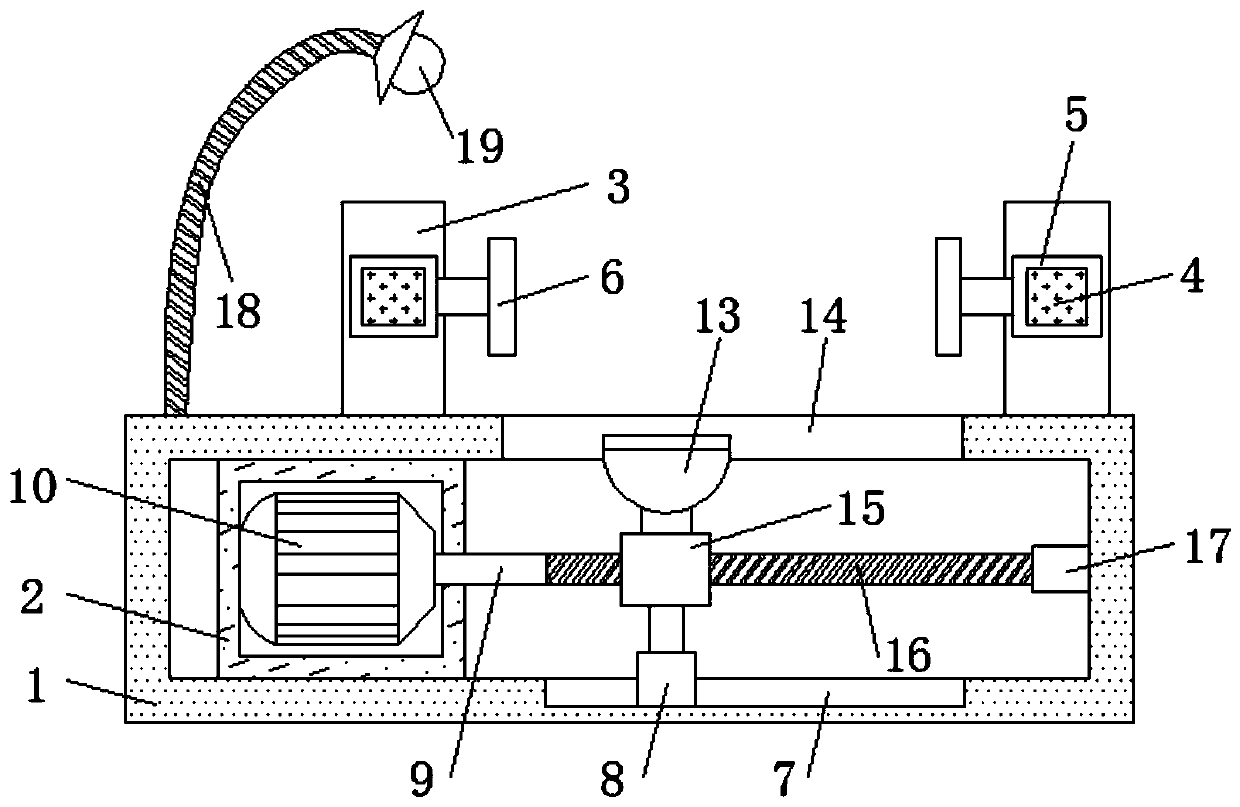

[0028] refer to image 3 , an electrical automation processing platform. Compared with Embodiment 1, this embodiment also includes a plastic elbow 18 and a lighting lamp 19. The plastic elbow 18 is fixed on one side of the outer wall of the top of the rectangular frame 1 by bolts, and 19 sets of lighting lamps Connected to one end of the plastic elbow 18.

[0029] During use, one side of the top of the rectangular frame 1 is provided with an illuminating lamp 19, which can provide illumination, and the plastic elbow 18 can be bent and stretched to change its position, so as to provide illumination to the dead corner of the workpiece conveniently.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com