A folio-type safety automatic paper cutter for green printing and printing method

A safe and automatic paper cutting machine technology, applied in metal processing and other directions, can solve the problems of easy errors, potential safety hazards, and reduced cutting quality, and achieve the effects of safe and convenient use, elimination of potential safety hazards, and scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

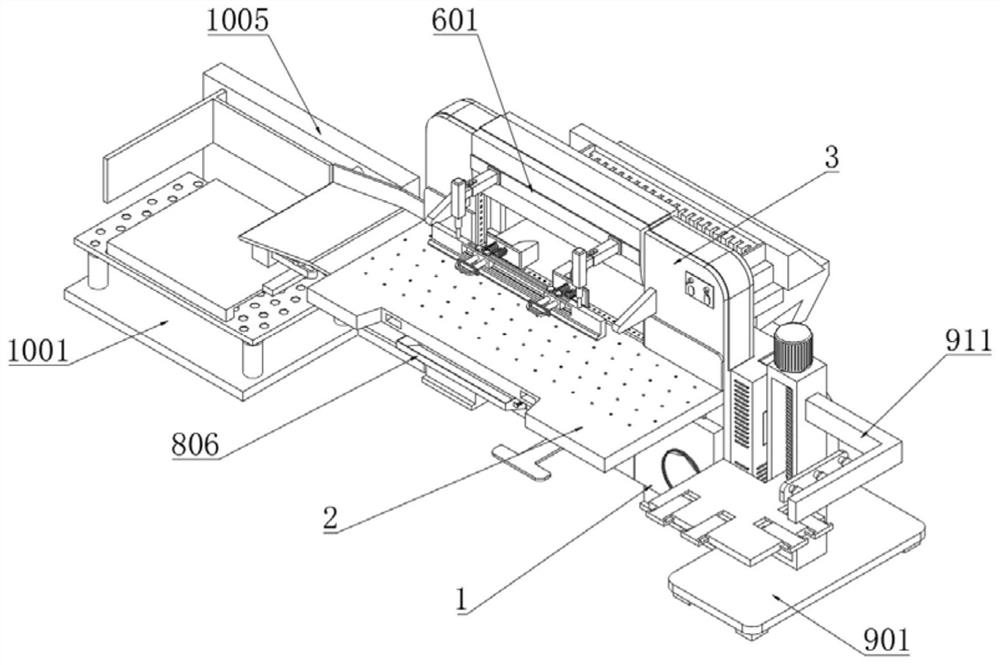

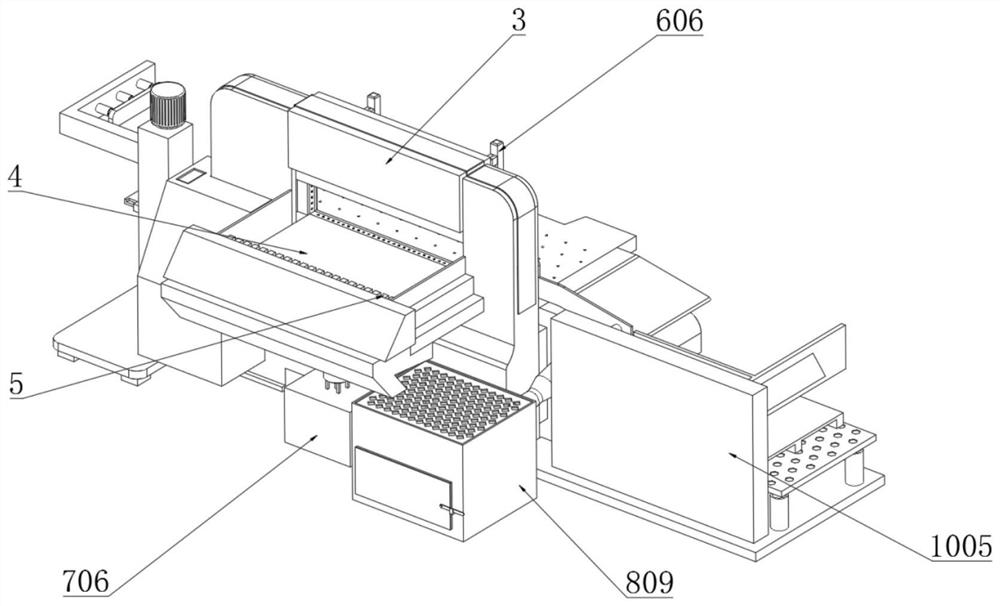

[0060] Example: such as Figure 1-9 As shown, the present invention provides a technical solution, a split-type safety automatic paper cutter for green printing, including a paper cutter base 1;

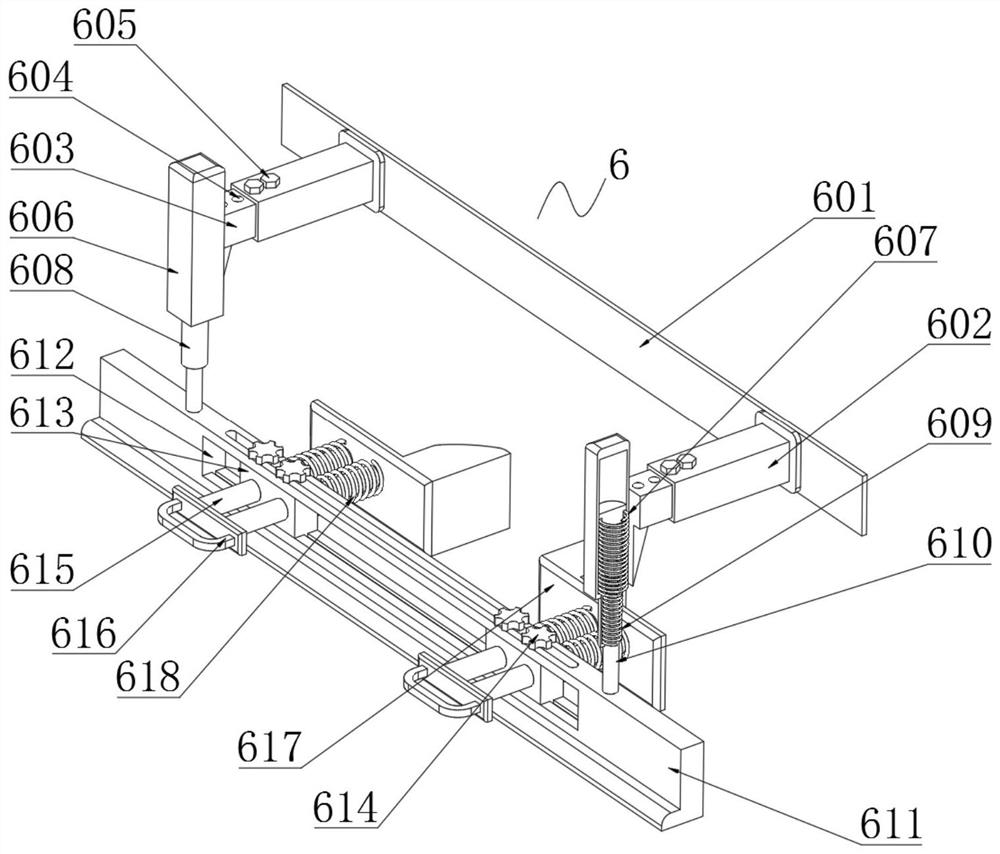

[0061] Auxiliary alignment mechanism 6, used to adjust the position of the paper to be cut, so that the sides of the paper are kept flush before cutting, so as to improve the cutting quality of the paper;

[0062] The cleaning mechanism 7 is used to collect the fiber debris generated during the cutting process to prevent the fiber debris from floating around and being inhaled by the operator;

[0063] The waste recycling mechanism 8 is used to quickly collect the waste paper strips generated by cutting, which reduces the work intensity of the operator;

[0064] The feeding mechanism 9 is used to lift up the paper to be cut and push the paper to be processed to the paper cutter;

[0065] The unloading mechanism 10 is used to store the cut papers and keep the papers neatly arranged d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com