Five-color material for ceramic underglaze painting and calligraphy, and application method thereof

A technology of underglaze multicolored and applied methods, which is applied in the field of ceramic painting, can solve problems such as stagnant pens, difficulty in fully expressing calligrapher's calligraphy level in ceramic calligraphy, and only a few words can be written at one time, so as to improve fluency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

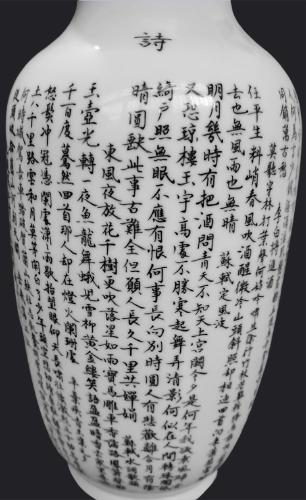

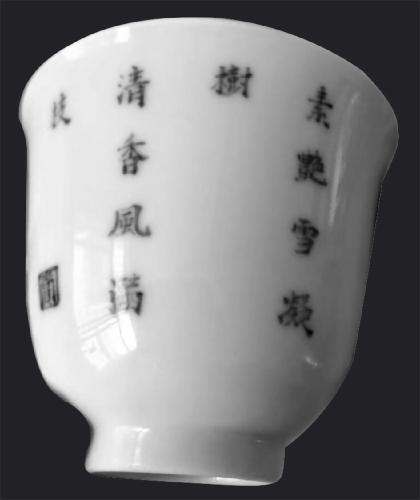

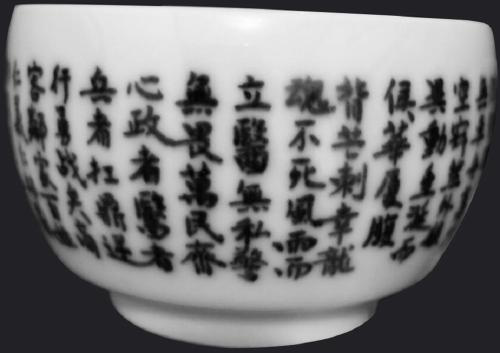

Image

Examples

Embodiment 1

[0040] Prepare ceramic underglaze calligraphy and painting colorful materials according to the following method.

[0041] Underglaze five-color material (underglaze blue and white dry material purchased from Jingdezhen Sharon Ceramic Machinery Co., Ltd.) 1000g

[0042] Overglaze color material (extra black black dry material for overglaze, purchased from Jingdezhen Sharon Ceramic Machinery Co., Ltd.) 320g

[0043] Oxalic acid 100g

[0044] Frankincense oil 540g;

[0045] Preparation method: add oxalic acid into underglaze multicolored materials, then add overglaze color materials, mix and stir for 40 minutes until uniform, then add frankincense oil to make honey-like material, and obtain ceramic underglaze painting and calligraphy multicolored materials.

[0046] Application method:

[0047] S1. The ceramic underglaze calligraphy and painting five-color material prepared by diluting with camphor oil, and then dipping it to write underglaze on the ceramic body, and the writi...

Embodiment 2

[0051] Prepare ceramic underglaze calligraphy and painting colorful materials according to the following method.

[0052] Underglaze multicolored material (underglaze bright red dry material purchased from Jingdezhen Sharon Ceramic Machinery Co., Ltd.) 1000g

[0053] Overglaze color material (red dry material for overglaze, purchased from Jingdezhen Sharon Ceramic Machinery Co., Ltd.) 100g

[0054] Phosphoric acid 120g

[0055] Frankincense oil 540g;

[0056] Preparation method: add phosphoric acid to underglaze multicolored material, then add overglaze color material, mix and stir for 30 minutes until uniform, then add frankincense oil to make honey-like material to obtain ceramic underglaze calligraphy and painting multicolored material.

[0057] Application method:

[0058] S1. The ceramic underglaze calligraphy and painting five-color material prepared by diluting with camphor oil, and then dipping it to write underglaze on the ceramic body, and the writing font is lowe...

Embodiment 3

[0062] Prepare ceramic underglaze calligraphy and painting colorful materials according to the following method.

[0063] Underglaze multicolored material (underglaze sapphire blue dry material purchased from Jingdezhen Sharon Ceramic Machinery Co., Ltd.) 1000g

[0064] Glaze color material (glaze sea blue dry material purchased from Jingdezhen Sharon Ceramic Machinery Co., Ltd.) 500g

[0066] Frankincense oil 425g;

[0067] Preparation method: Add sodium carbonate to underglaze multicolored material, then add overglaze color material, mix and stir for 30 minutes until uniform, then add frankincense oil to make honey-like material, and obtain ceramic underglaze painting and calligraphy multicolored material.

[0068] Application method:

[0069] S1. The ceramic underglaze calligraphy and painting five-color material prepared by diluting with camphor oil, and then dipping it to write underglaze on the ceramic body, and the writing font is lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com