A kind of oxygen barrier butyl rubber and preparation method thereof

A technology of butyl rubber and butyl rubber, applied in adhesives, non-polymer adhesive additives, adhesive types, etc., can solve problems such as lack of packaging materials, inability to have mass production value, oxygen oxidation failure, etc. Achieve the effects of increasing crosslink density and molecular compactness, reducing the possibility of oxygen penetration, and slowing down the consumption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of oxygen barrier butyl rubber in the specific embodiment comprises the steps:

[0033] Reinforcing fillers and filling fillers are first dehydrated in a vacuum oven at 150°C for 2 hours;

[0034] Add butyl rubber, tackifier, silane-modified olefin polymer, reinforcing filler, and filling filler into the kneader according to parts by weight, control the temperature within the range of 100-140°C, knead into agglomerates and vacuumize for 30 Minutes, control the vacuum degree ≤ -0.09MPa;

[0035] Then add the barrier filler to the mixture obtained in step (1), mix quickly and evenly, knead under the protection of carbon dioxide or argon until uniformly formed into agglomerates, the kneading temperature needs to be adjusted according to the type of barrier filler added: when using reduced iron powder , It is necessary to cool down the kneader to between 80°C and 100°C in advance, and at the same time, it needs to be filled with inert gas for more th...

Embodiment 1

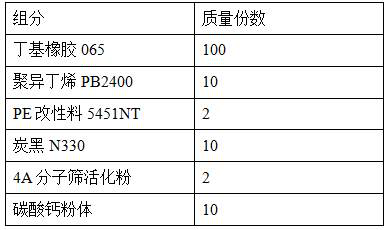

[0037] The specific selection of each raw material is shown in the table below:

[0038]

Embodiment 2

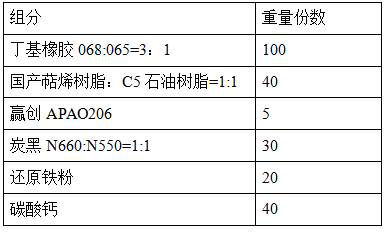

[0040] It is basically the same as Example 1 except that the composition of the raw materials is different, and the selection of each raw material is shown in the following table:

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap