Non-adhesive seed crystal type tantalum crucible and crystal growing method

A tantalum crucible, non-adhesive technology, applied in the field of semiconductor manufacturing equipment and processes, to achieve the effects of high melting point, saving the use of glue, excellent chemical corrosion resistance and thermal shock performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

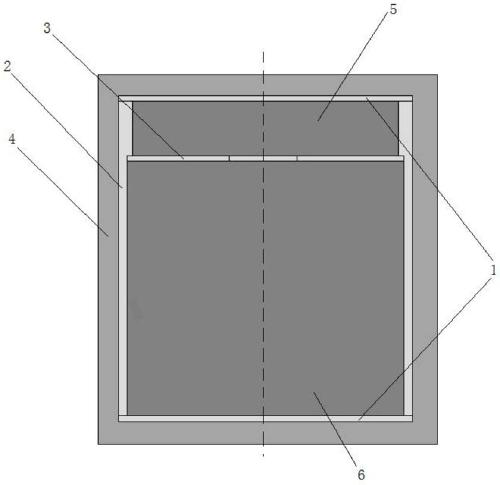

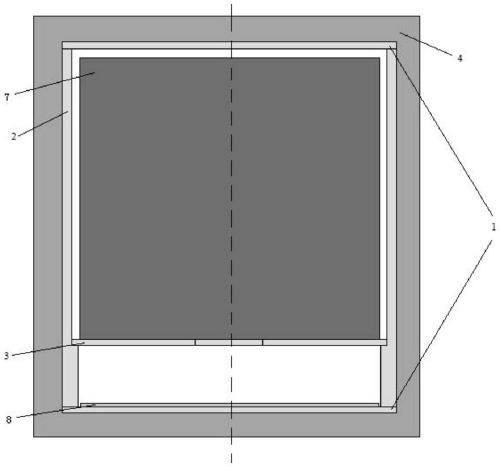

[0046] Specific implementation mode two: combination Figure 1-Figure 4 This embodiment will be described. In the non-adhesive seed crystal tantalum crucible of this embodiment, the inner diameter difference between the two ends of the tantalum crucible cylinder 2 is within the range of 1.8 mm to 2 mm.

specific Embodiment approach 3

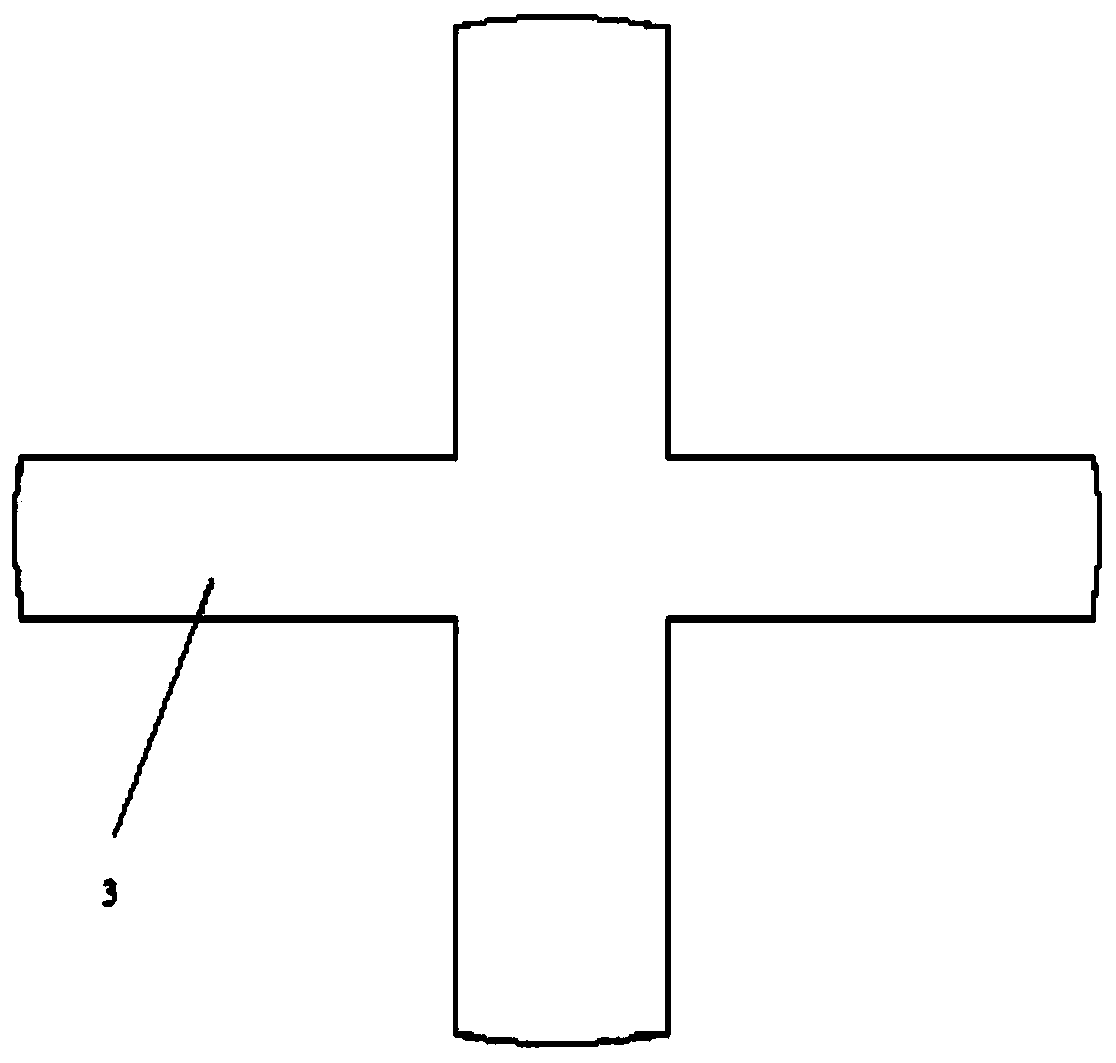

[0047] Specific implementation mode three: combination Figure 1-Figure 4 This embodiment will be described. In the non-adhesive seed crystal tantalum crucible of this embodiment, the thickness of the cross tantalum sheet 3 is within the range of 1 mm to 1.5 mm.

[0048] Specific implementation mode four: combination Figure 1-Figure 4 Describe this embodiment, a non-adhesive seed crystal tantalum crucible of this embodiment, the four edges of the cross tantalum sheet 3 are arc-shaped, and the arcs of the four arcs are the same as the arcs of the inner surface of the tantalum crucible cylinder 2 Consistently, the length of the cross tantalum sheet 3 is slightly smaller than the inner diameter of the end of the tantalum crucible cylinder 2 with a larger inner diameter, and the difference is within 0.6mm-0.8mm.

[0049] Specific implementation mode five: combination Figure 1-Figure 4 To illustrate this embodiment, a method for growing crystals in a non-adhesive seed crystal t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap