Automatic assembling system for pipe culvert prefabricated member and construction method

A prefabricated component and assembly system technology, which is applied in the sewer pipeline system, general control system, control/regulation system, etc., can solve the problems of manual measurement, large equipment system, inability to flexibly apply to different types and sizes of projects, etc. Achieve the effect of accurate and reliable alignment installation, realize automation, and eliminate unstable influencing factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

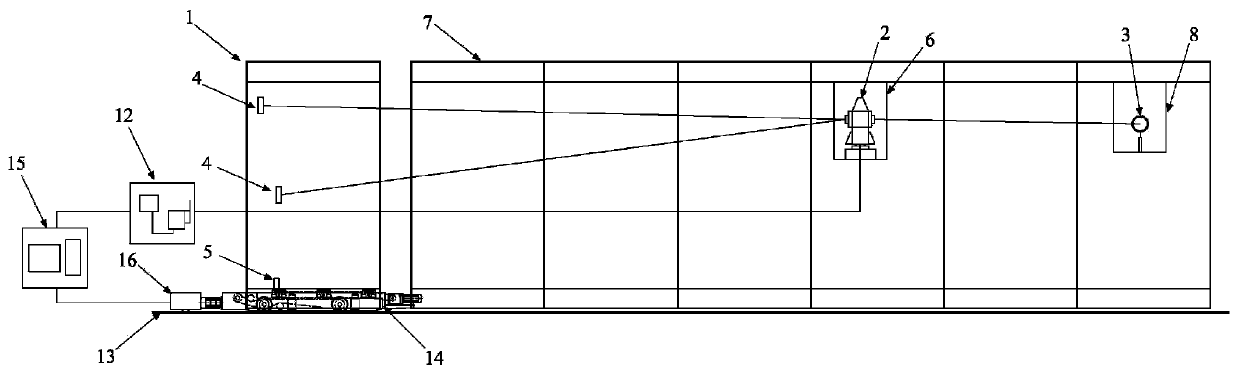

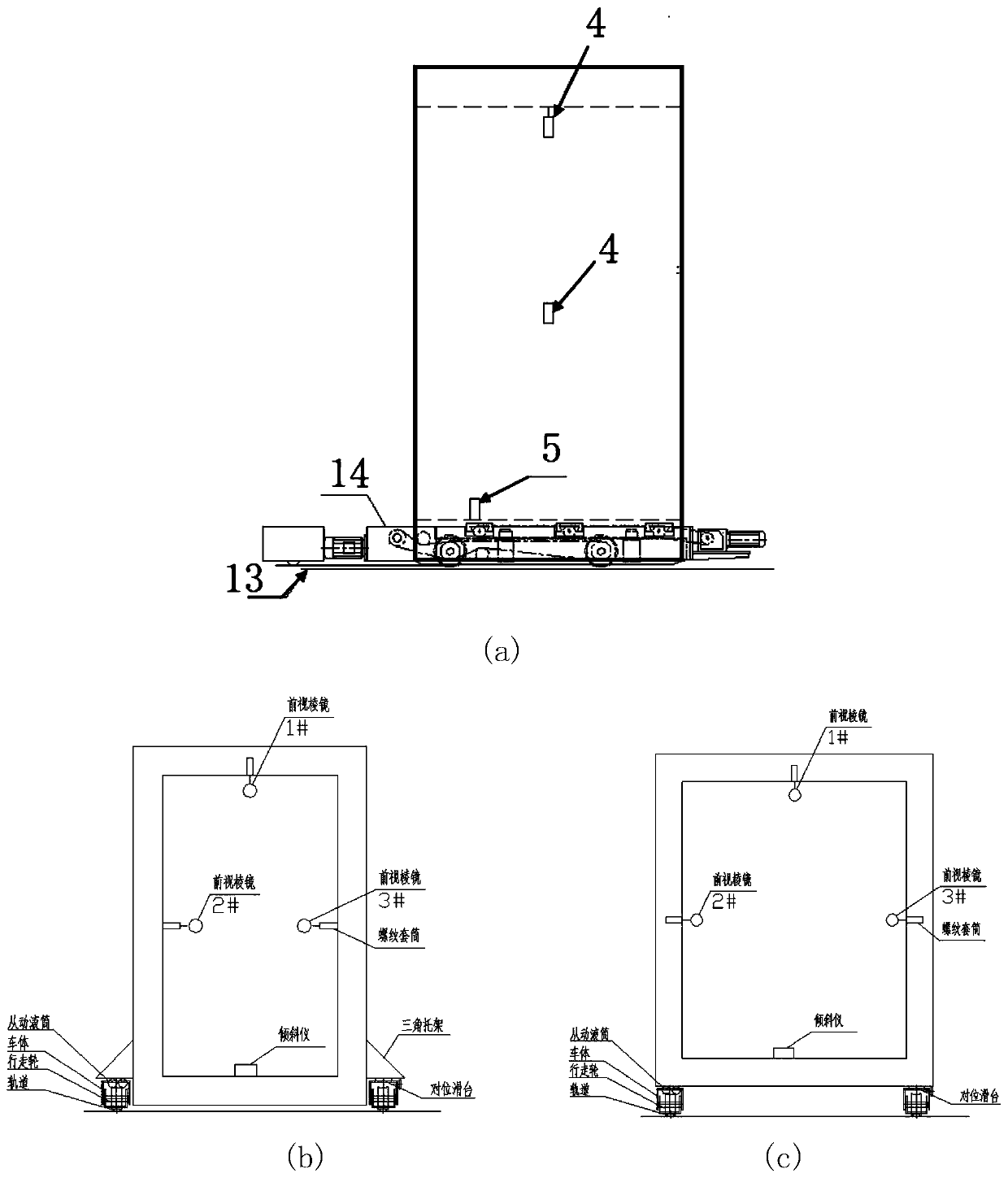

[0058] The prefabricated pipe culvert members shown in the following embodiments are all rectangular pipe culvert members. It should be noted that this technology is applicable to the automatic assembly of rectangular, circular and other special-shaped pipe and culvert components. Rectangular culvert components are more difficult to implement than circular culvert components. The difficulty is that the effect of rolling angle cannot be ignored for rectangular culvert members, but the effect of rolling angle can be ignored for circular culvert members.

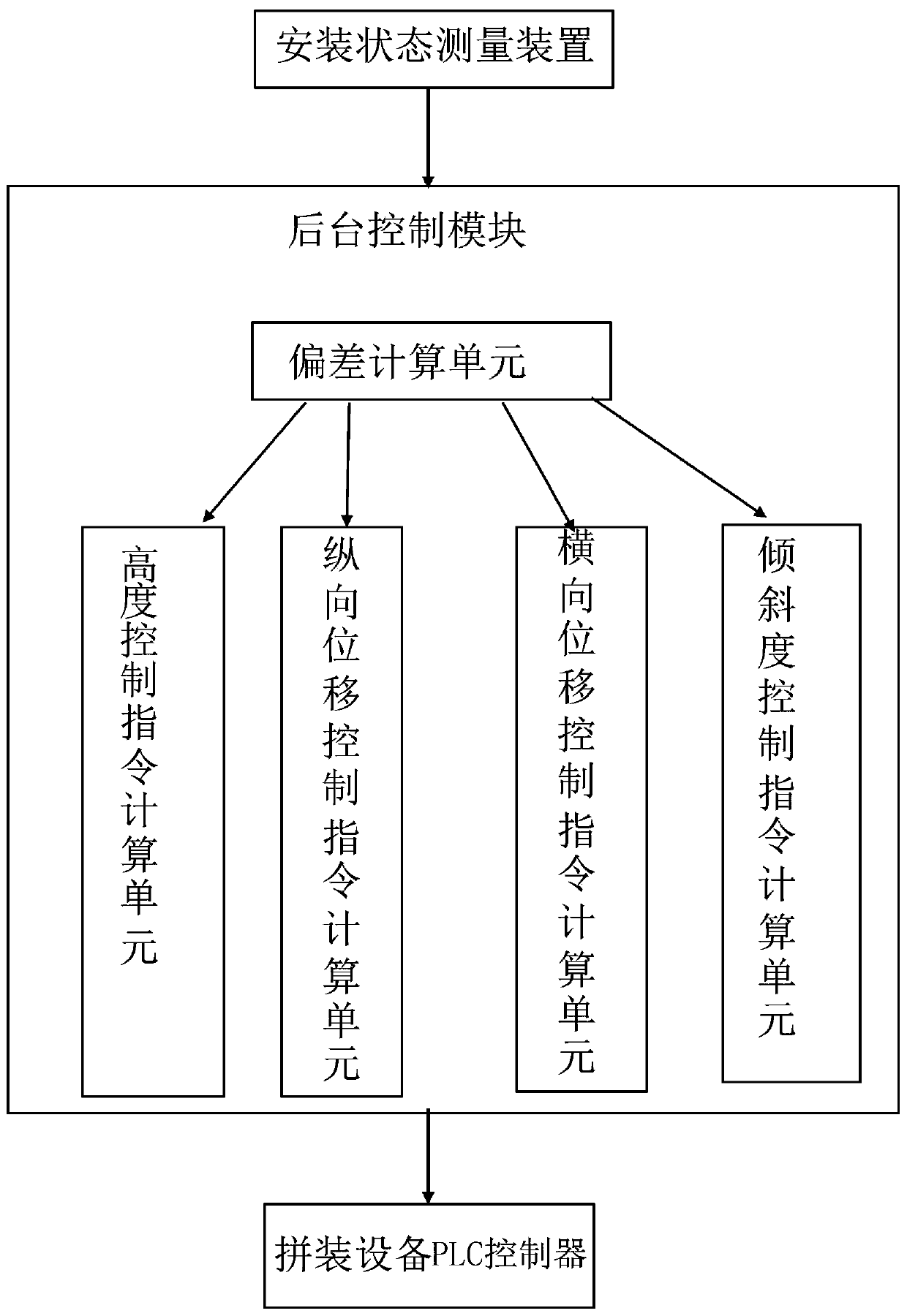

[0059] like figure 1 As shown, an automatic assembly system for pipe and culvert prefabricated components provided by an embodiment of the present invention includes:

[0060] The installation status measuring device of the prefabricated components to be installed is used to measure the actual installation status of the prefabricated components to be installed; the installation status measurement device of the prefabricated c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com