Waste rock slurry pipeline coordinated method for coal mining working face

A coal mining face and working face technology, which is applied to filling materials, mining equipment, earth cube drilling and mining, etc., can solve the problems of high filling cost, easy to block pipes, and low amount of waste rock treatment, and achieve the protection of the ecological environment and reduce the amount of filling Cost, the effect of improving filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

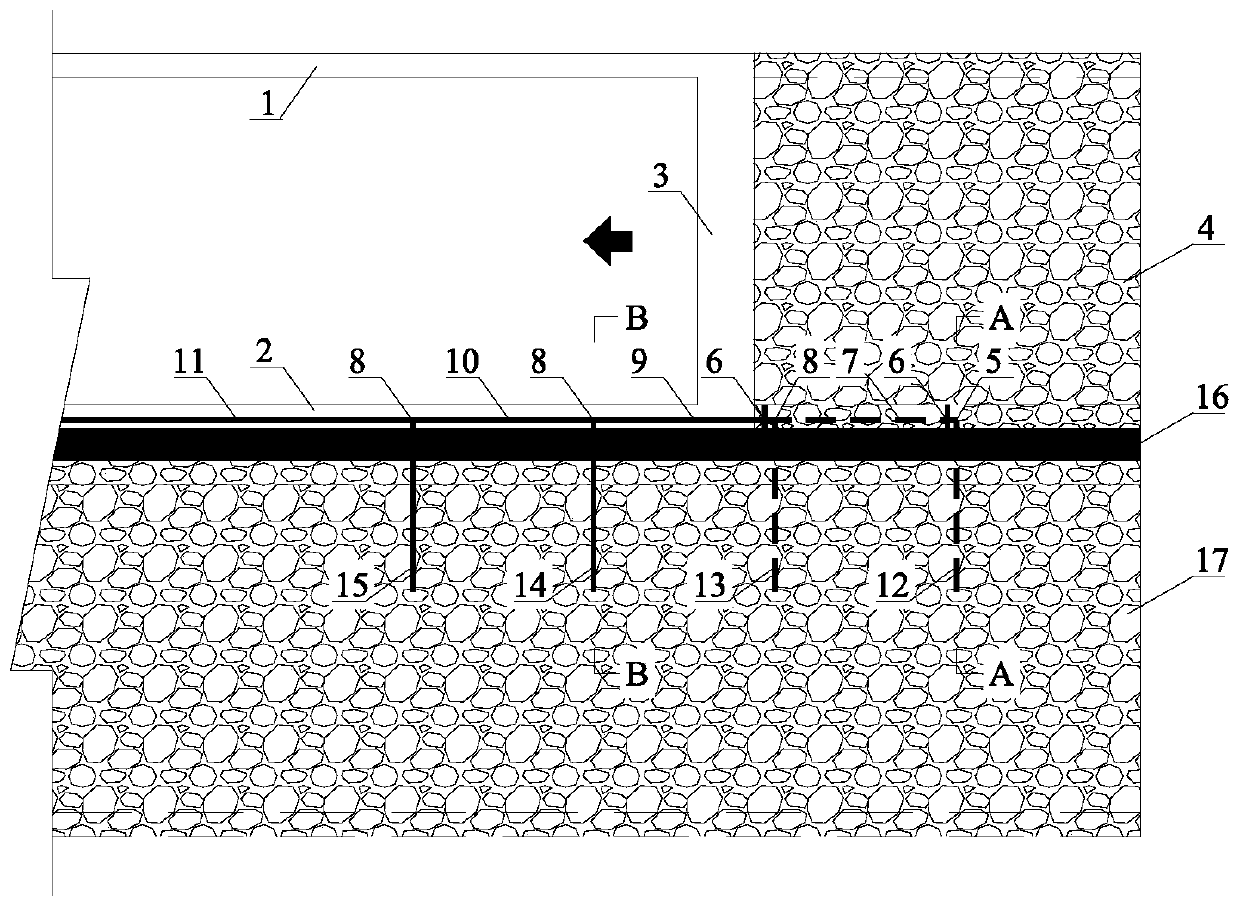

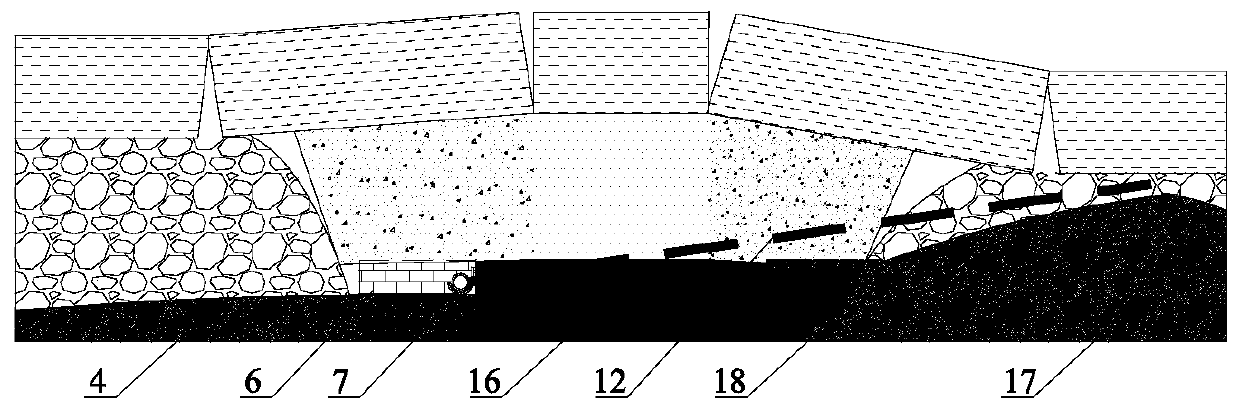

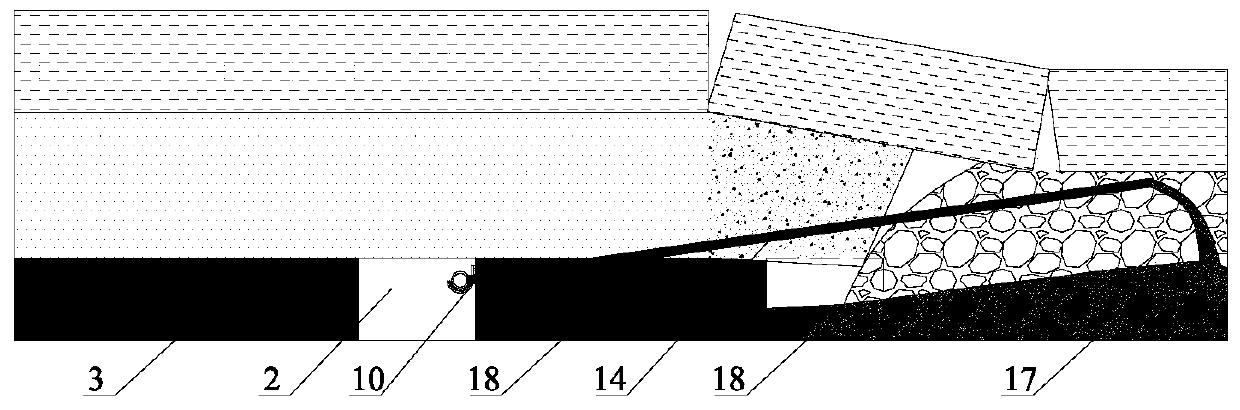

[0033] The buried depth of the coal seam in a mine working face in Inner Mongolia is 350-400m, the average thickness of the coal seam is 3.5m, the length of the working face is 254m, the width of the auxiliary roadway is 5.0m, and the height is 3.5m. The coal pillars between adjacent working faces are 20m. The length of the arc-shaped triangular block in the working face is about 14.5m, and the height of the caving zone in the goaf of the adjacent working face is about 11.8m.

[0034] 1. On the coal wall on the side of the coal pillar in the auxiliary transportation roadway, drill adjacent grouting holes every 40m to the adjacent mined-out area at an angle of 20°, the drilling length is about 35m, and lower the adjacent grouting pipes after completion;

[0035] 2. Install a pipe hook every 10m at the 2.8m coal wall on the side of the coal pillar in the auxiliary transportation lane, and place the low-level grouting pipe on the pipe trench;

[0036] 3. Connect the adjacent grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com