Coal mine underground gangue in-situ separation and in-situ grouting filling method

A gangue and sorting technology, which is applied in filling materials, chemical instruments and methods, solid separation, etc., can solve problems that cannot be widely used, threats to the ecological environment, low filling efficiency, etc., and achieve reduced surface subsidence, large filling capacity, The effect of increasing lift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

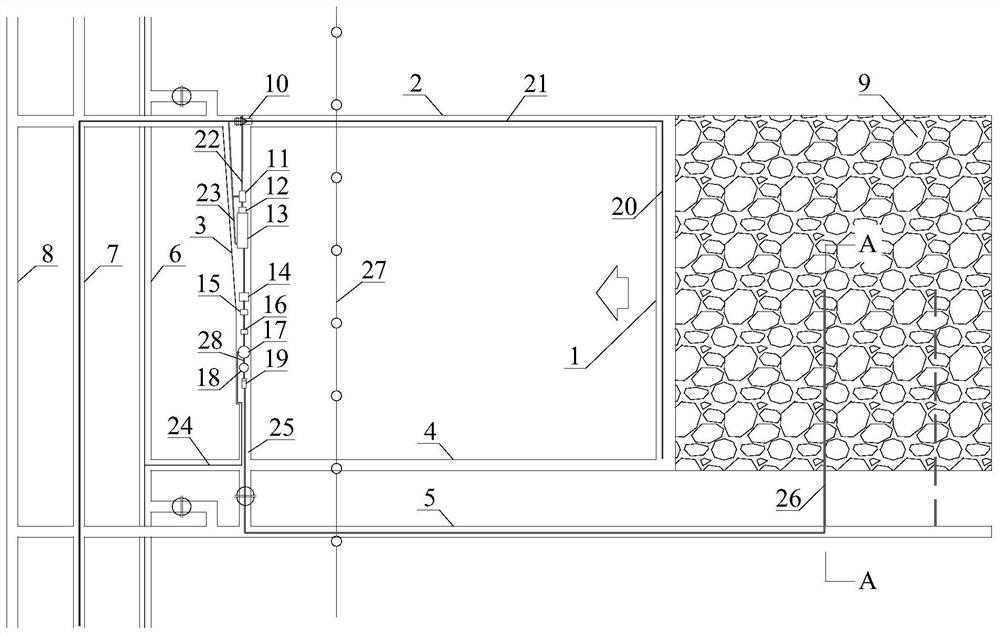

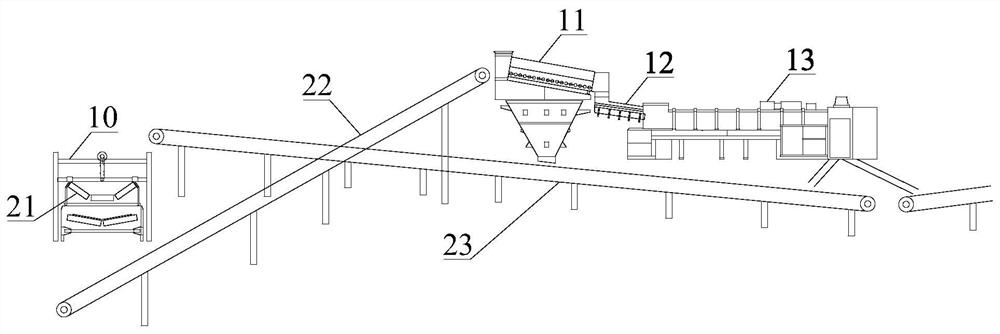

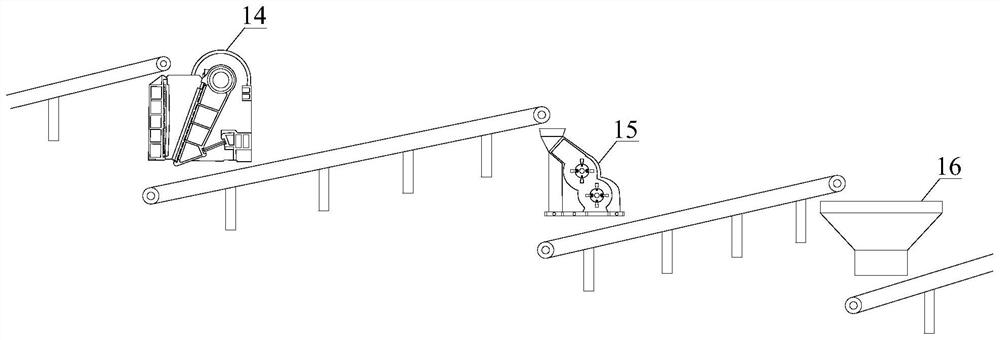

[0026] For better understanding of the present invention, the present invention will be further described below with reference to the accompanying drawings and embodiments.

[0027] like Figure 1 to Figure 5 As shown in the figure, the present invention provides a method for in-situ grouting and filling of coal mine gangue in situ sorting. The method first uses a plow unloader 10 to transfer the raw coal on the coal transport belt 21 in the transport lane to the sorting and pulping. Then, the raw coal is divided into clean coal, fine coal and gangue by the screening and sorting system. The clean coal and fine coal are returned to the coal conveying belt 21 in the transport lane through the coal return belt 23, and the gangue passes through the crushing system and the pulping system. It is made into a slurry with a preset concentration, and finally, the gangue slurry is transported by the grouting pump 19 through the grouting pipe 25 through the transportation lane 5 of the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com