A petroleum and petrochemical valve with a locking structure

A locking structure and valve technology, applied to valve details, valve devices, sliding valves, etc., can solve problems such as inability to realize fast opening and closing of valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

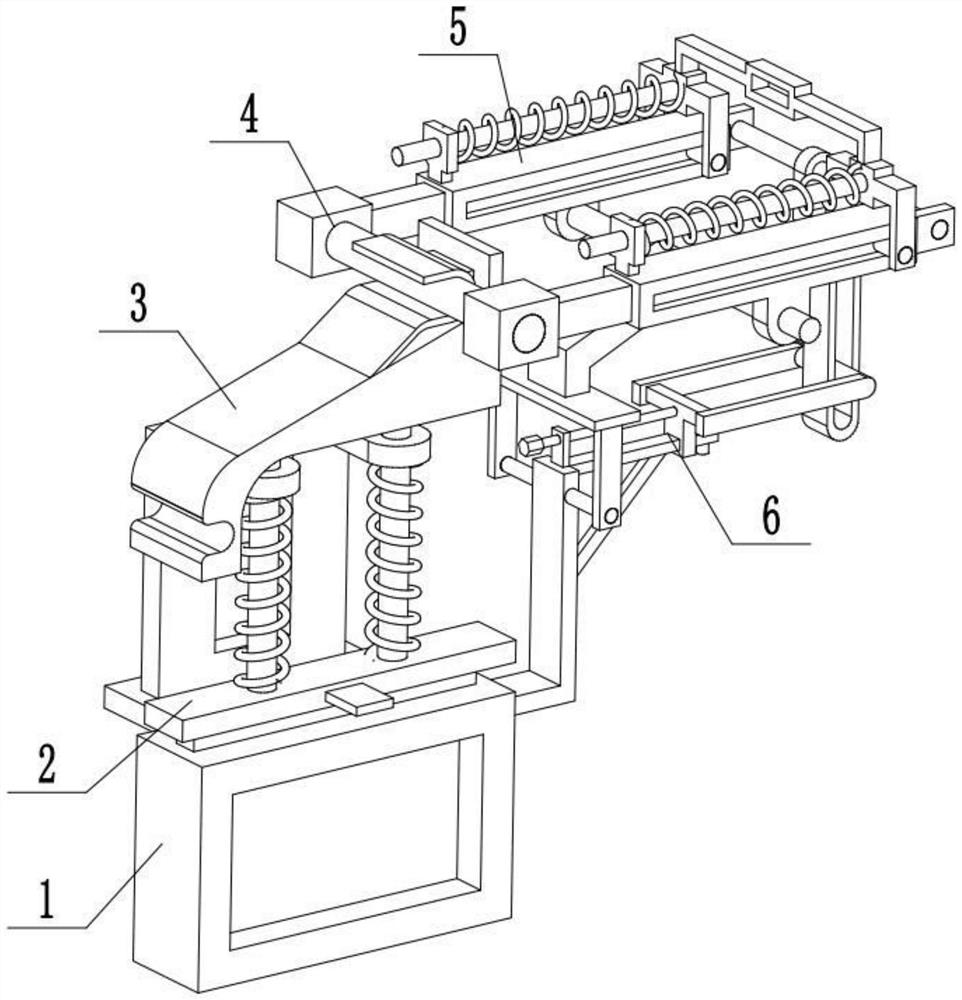

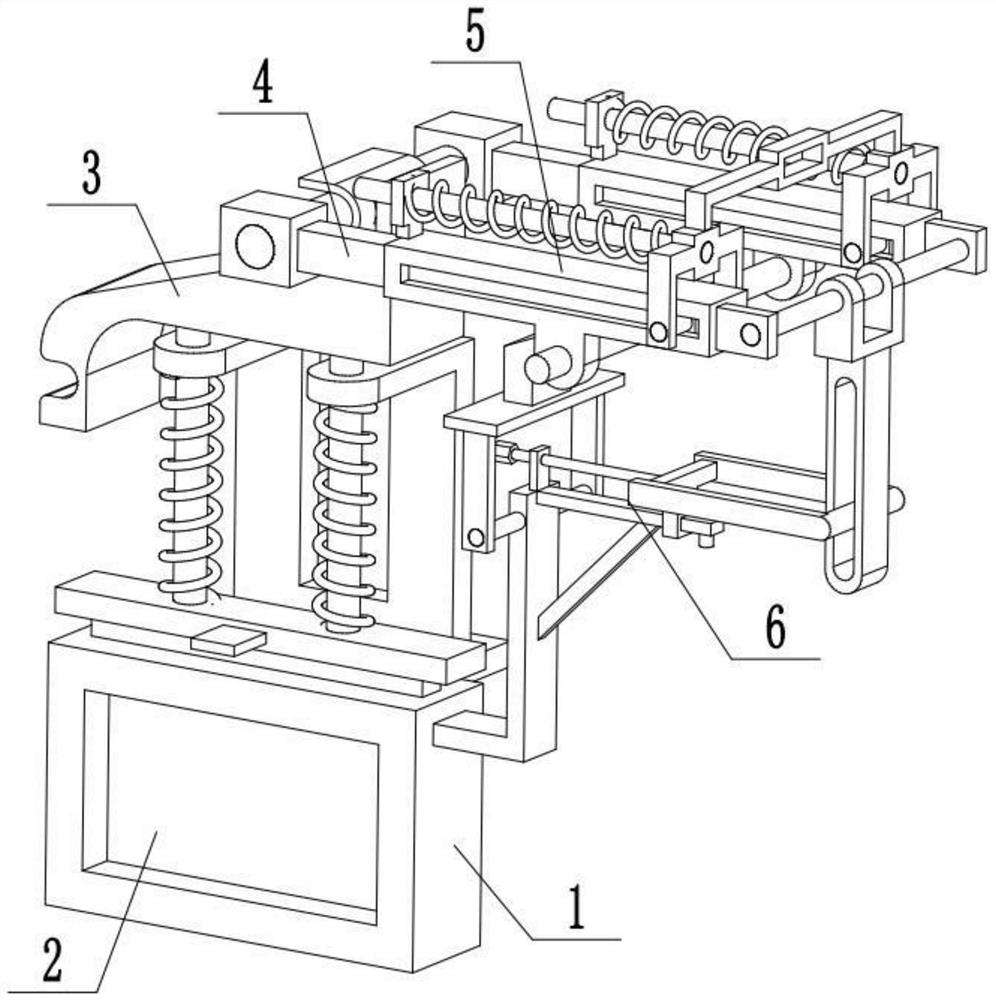

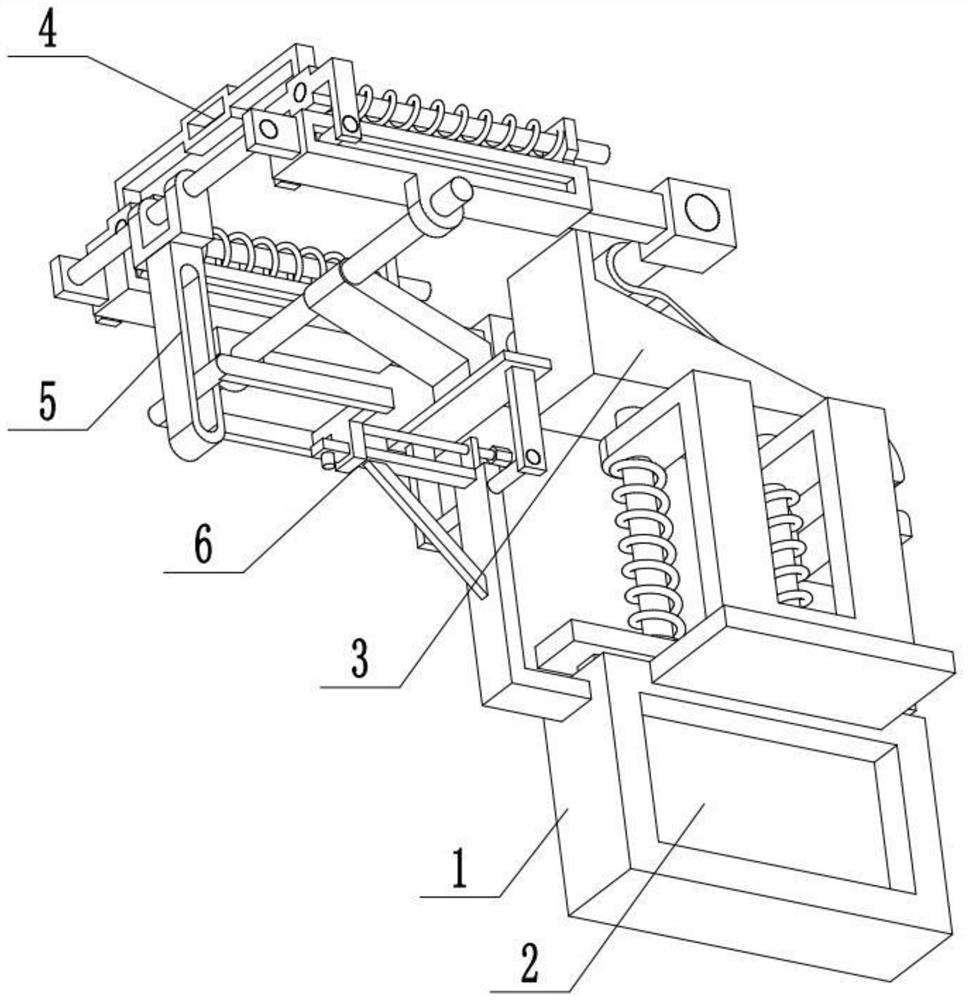

[0028] Combine below Figure 1-10 Describe this embodiment, a petroleum and petrochemical valve with a locking structure, including a valve housing 1, a valve plate 2, a locking piece 3, a locking piece 4, a locking piece sliding seat 5, and a locking adjustment mechanism 6. The valve plate 2 described above is slidably connected in the valve housing 1, the locking piece 3 is arranged on the upper end of the valve plate 2, the locking piece 4 is connected with the locking piece 3, and the locking piece 4 is movably connected to the locking piece sliding On the seat 5 , the locking member sliding seat 5 is arranged on the locking adjusting mechanism 6 , the locking adjusting mechanism 6 is connected with the locking member sliding seat 5 , and the locking adjusting mechanism 6 is arranged on the valve housing 1 . When in use, the valve housing 1 is in a closed state under normal conditions, and the clamping part 4 is clamped on the right end of the locking part 3, and the clamp...

specific Embodiment approach 2

[0030] Combine below Figure 1-10To illustrate this embodiment, the valve plate 2 is sealed and slidably connected in the valve housing 1, the valve housing 1 is provided with a fixing frame 1-1, and the upper end of the valve plate 2 is fixedly connected to two spring sleeves Rod 2-1, the two spring sleeve rods 2-1 are all slidingly fitted and connected to the fixed frame 1-1, and a compression spring 2-2 is respectively sleeved on the two spring sleeve rods 2-1; the compression spring 2- The two ends of 2 are respectively fixedly connected to the fixed frame 1-1 and the valve plate 2; the upper end of the valve plate 2 is fixedly connected to the dial 2-3; the locking member 3 is arranged on the two spring sleeve rods 2-1. When the plate 2-3 is pulled upward, it drives the valve plate 2 to move upward, and the valve plate 2 opens the valve housing 1 to realize rapid opening. At the same time, the two compression springs 2-2 are compressed to store force. When the valve plat...

specific Embodiment approach 3

[0032] Combine below Figure 1-10 To illustrate this embodiment, the top surface of the locking member 3 is inclined upward from left to right to form a right-angled triangle structure, and the locking member 3 is fixedly connected to the upper ends of the two spring sleeve rods 2-1; the locking member 4 It is clamped on the right end of the locking piece 3.

[0033] The left end of the locking member 3 is provided with a downward extension, and the extension is provided with a locking groove 3-1, and the right end of the locking member 3 is fixedly connected to the connecting plate 3-2, and the U-shaped locking seat 3-3 is fixedly connected to the connection plate 3-2, and the transition slant plate 3-4 is fixedly connected to the lower end of the U-shaped card seat 3-3 and the slope of the locking piece 3; the transition slant plate 3-4 is connected to the U-shaped The joint of the card position seat 3-3 is a transitional arc surface; the card position member 4 is clamped i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com