Central flue system and air quantity self-adaptive adjusting method of central flue system

A flue system and central technology, which is applied to the central flue system and its air volume adaptive adjustment field, can solve the problems of unusable main engine, the flue is full of grease, and the adjustment is difficult, so as to meet the flow demand and improve the use. Longevity, the effect of reducing the frequency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

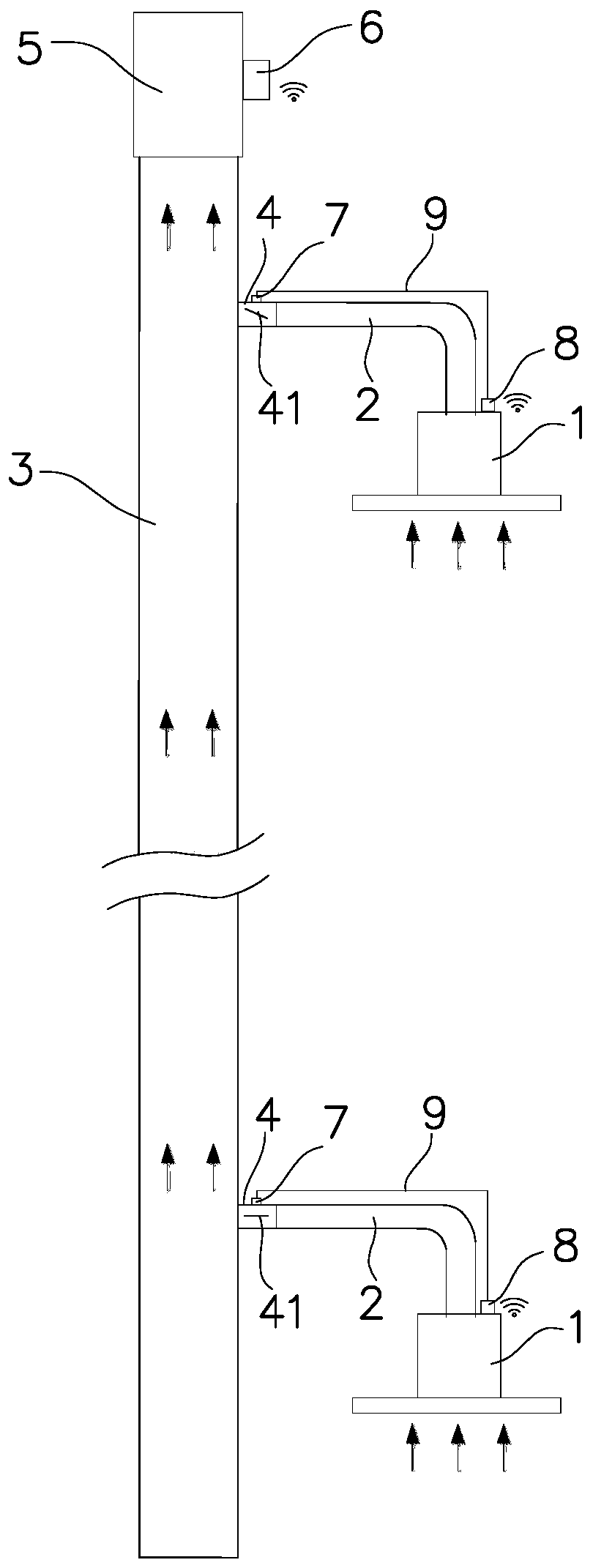

[0032] Such as figure 2 with image 3 As shown, the central flue system in this embodiment includes range hoods 1 installed on different floors, and the range hood 1 includes a fan (not shown in the figure), that is, the indoor range hood 1 can generate power. The air outlet of each range hood 1 is connected with the common flue 3 through its own smoke pipe 2, and an electric check valve 4 is installed in each smoke pipe 2, and the electric check valve 4 includes a valve plate 41 , the flue main fan 5 is installed in the common flue 3 .

[0033] The central flue system also includes a main control system 6, an electric check valve control system 7 and a range hood control system 8, wherein the main control system 6 is installed on the roof, and the electric check valve control system 7 is installed on the smoke pipe. 2, the range hood cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com