Step-by-step elasticoplastic deformation mechanical metamaterial suitable for multiple working conditions

An elastic-plastic deformation and metamaterial technology, applied in the field of mechanical metamaterials, can solve the problems of low energy absorption efficiency, cannot be reused, and has not yet been designed, and achieves increased energy absorption efficiency, programmability, and good buffering effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

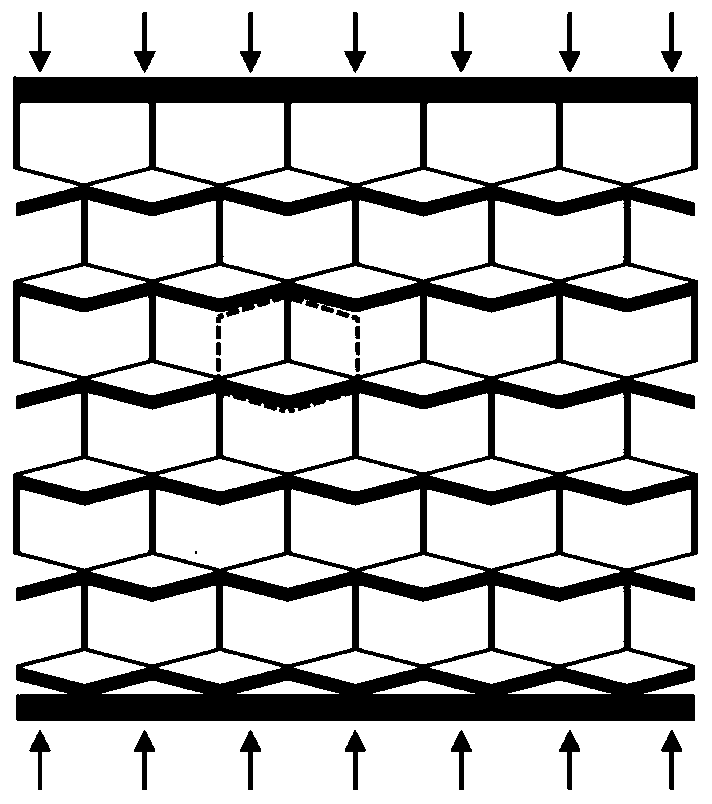

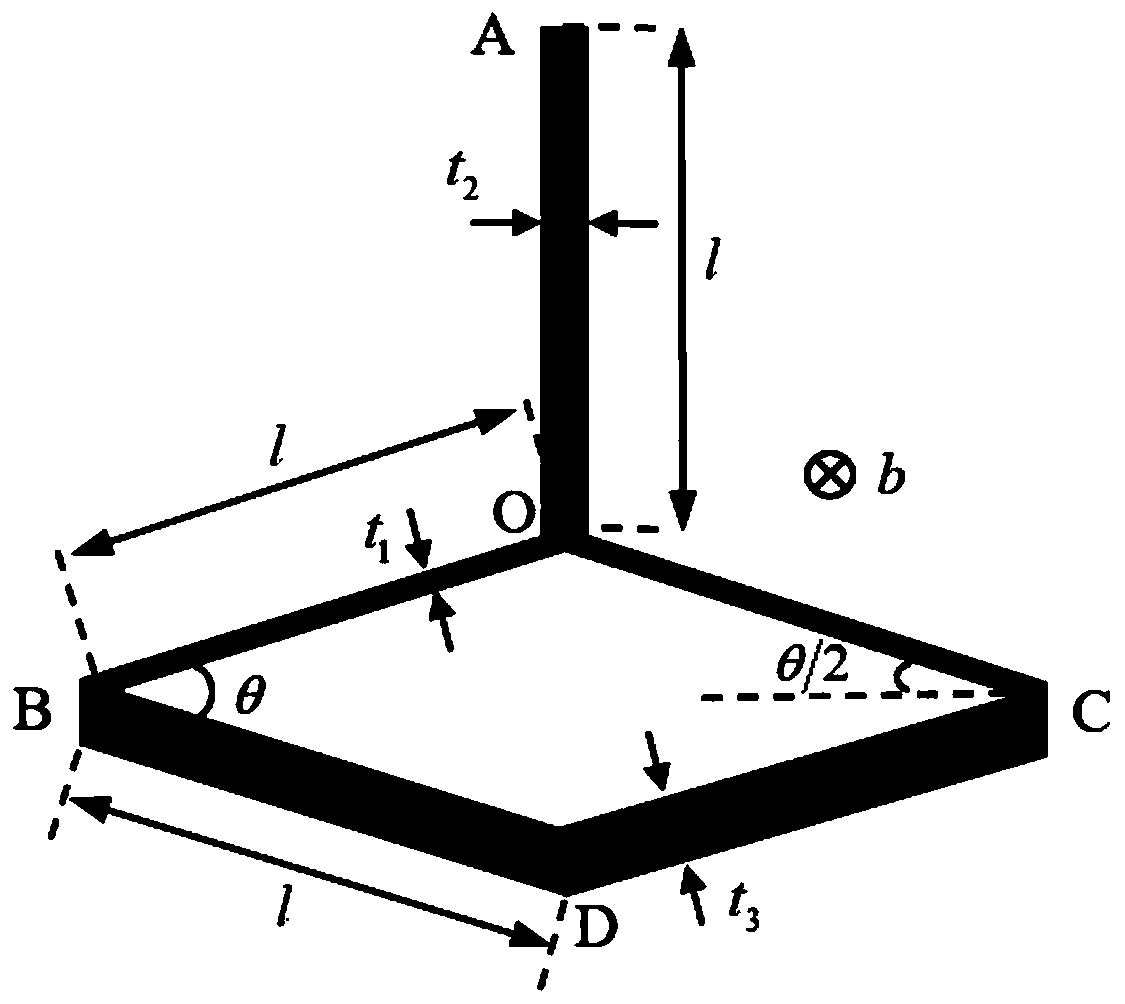

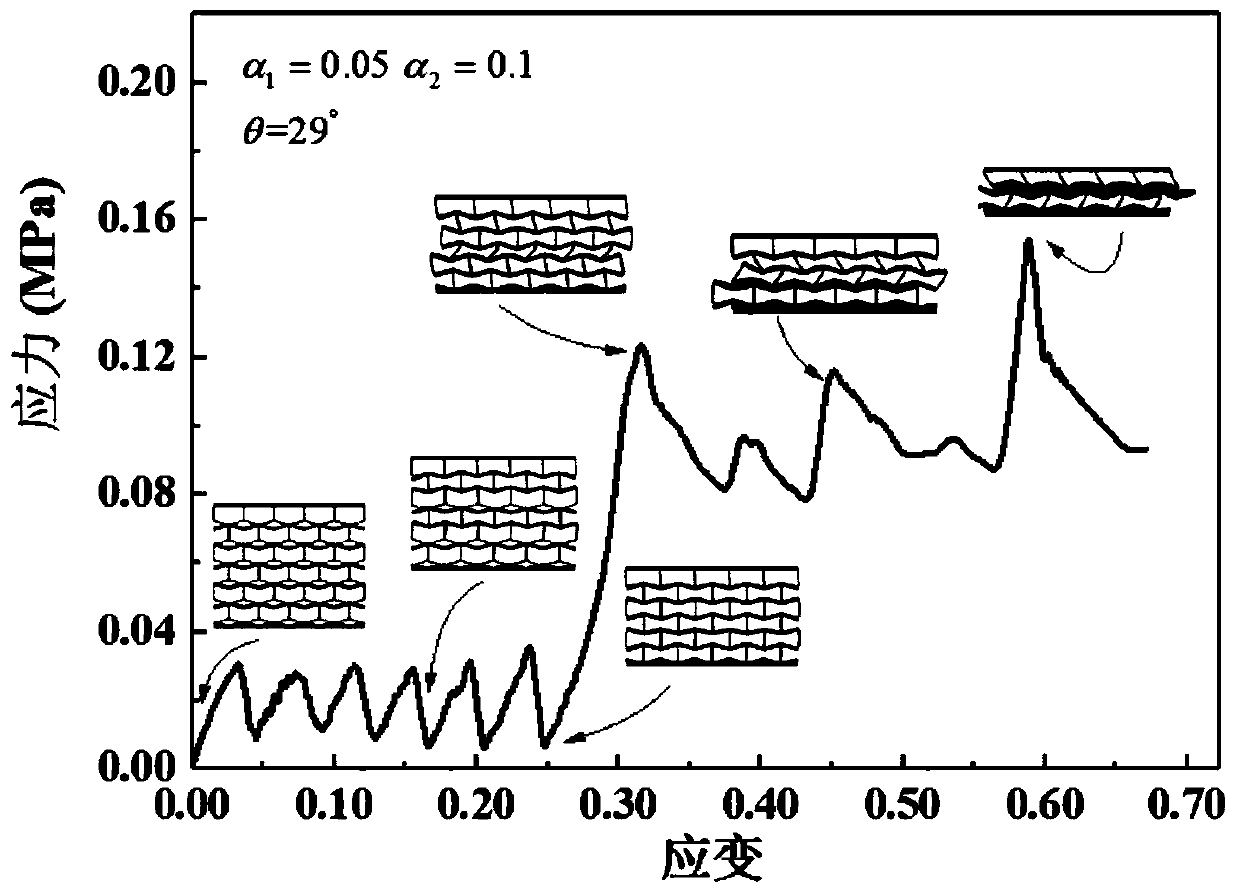

[0030] This embodiment uses elastoplastic material (nylon material) to design a mechanical metamaterial with two-step deformation (such as figure 1 Shown), the cells that make up the metamaterial (such as figure 2 (Shown) is composed of 5 rods (vertical rod AO, oblique rod BO, oblique rod CO, support rod BD, and support rod CD) located on the same plane. The length of the five rods is 10mm, two of which are oblique Rod slenderness ratio α 1 Is 0.05, and the angle between the oblique rod BO and the support rod BD is 29°, the slenderness ratio of the vertical rod is α 2 It is 0.1, the slenderness ratio of the support rod is 0.2, and the thickness of the above 5 rods in the direction perpendicular to the plane is 15 mm. In the compression process, firstly the two oblique bars are deformed. Because the strain produced is small, the deformation and buckling mode is elastic deformation, which is recoverable, corresponding to the first stress platform; in the oblique bar compaction Af...

Embodiment 2

[0034] The same conditions are used as in Example 1, except that the slenderness ratio α 1 Changed to 0.03, the force-displacement curve of the obtained metamaterial is as Figure 5 Shown.

Embodiment 3

[0036] The same conditions are used as in Example 1, except that the slenderness ratio α 1 Changed to 0.04, the force-displacement curve of the obtained metamaterial is as Image 6 Shown.

[0037] It can be seen from Examples 2 and 3 that by changing the geometric parameters of the slenderness ratio of the inclined rod, the height of the dual platform can be adjusted to adapt to different loading conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com