Protection device for ocean platform vertical pipe

A technology for protection devices and offshore platforms, applied in pipeline protection, lighting devices, components of lighting devices, etc., can solve the problems of damage to the surface layer structure of flexible risers, damage to the internal structure of flexible pipes, and complex working environment of flexible pipes, etc. Achieving good anti-collision effect, reducing energy exchange and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

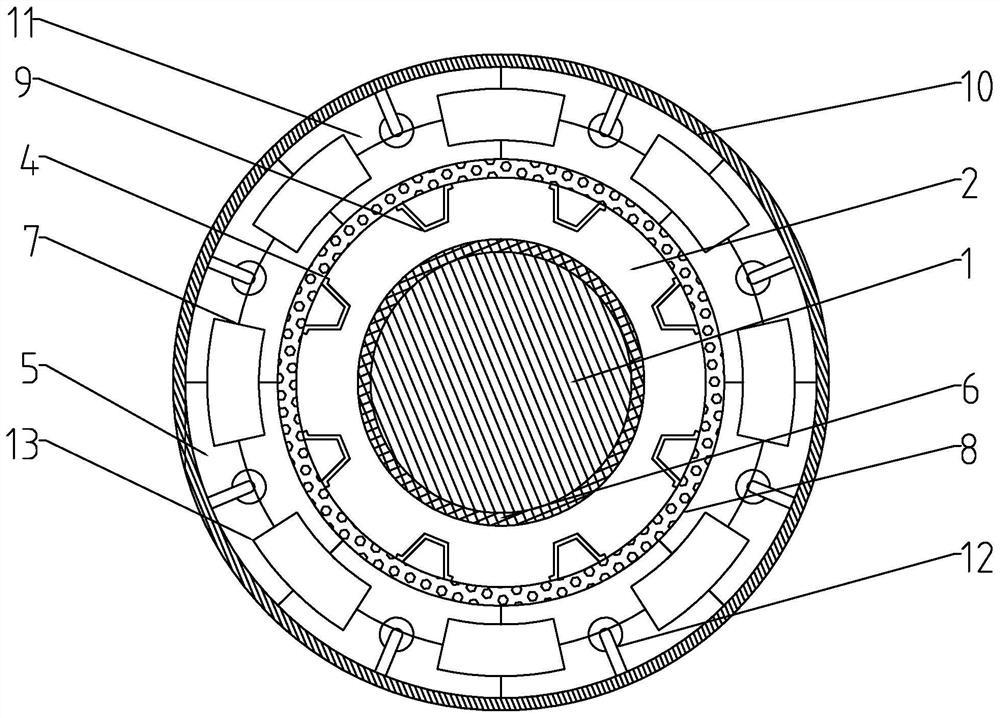

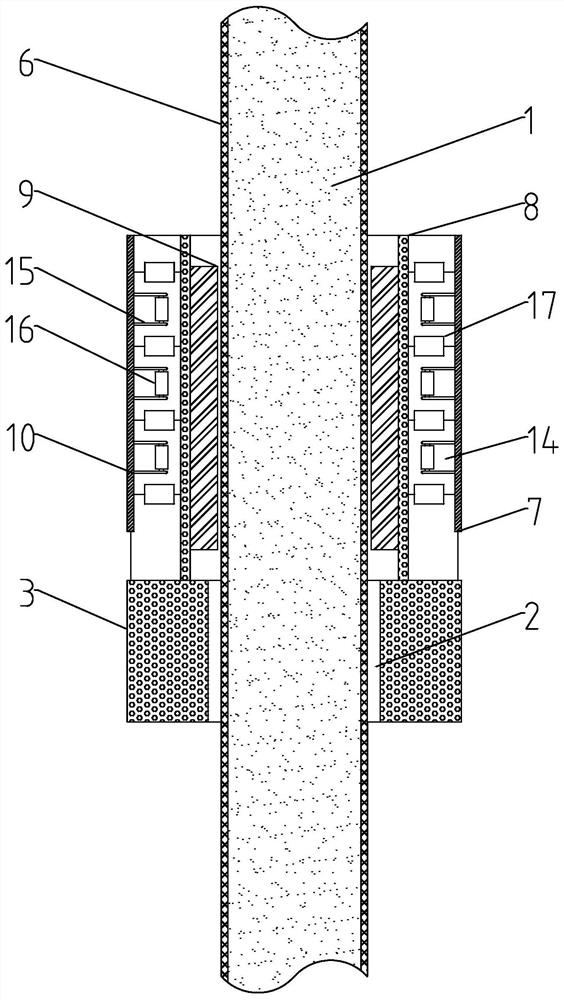

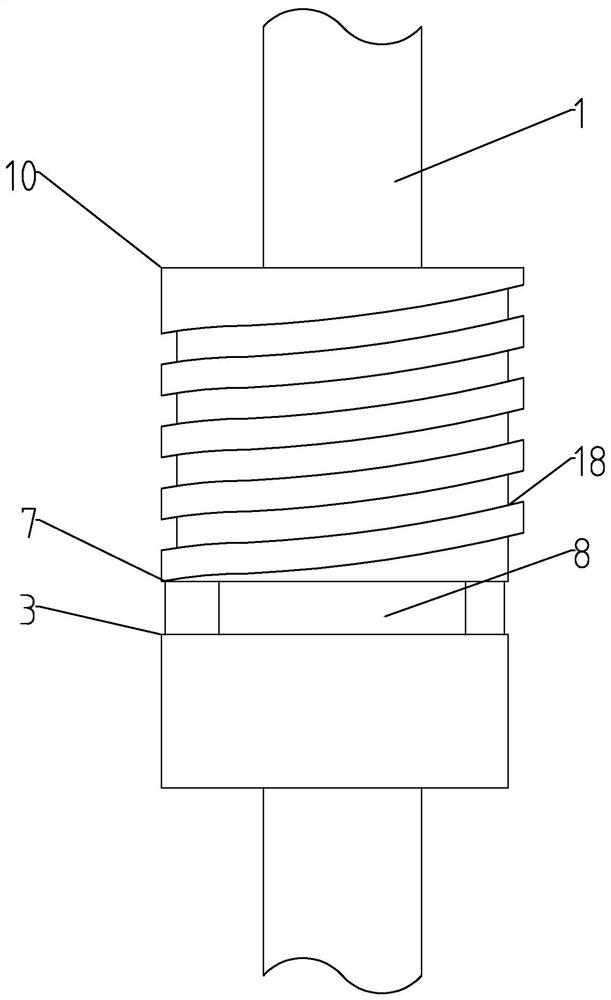

[0039] Such as figure 1 , 2 The shown offshore platform riser protection device includes a buoy 3 with a through hole 2, and the riser 1 is in the through hole 2 of the buoy 3; the protection device also includes an inner protection component 4, an outer protection component 5 and The protective layer 6, the inner protection assembly 4 includes a buffer ring 8 surrounding the riser 1 and the fender 9 arranged between the riser 1 and the buffer ring 8; the outer protection assembly 5 includes a protective sleeve 10 and is arranged on the buffer The buffer structure 11 between the ring 8 and the casing 10 ; the protective layer 6 is wrapped around the outer wall of the riser 1 .

[0040] Through the multi-stage energy consumption of the outer layer protection component 5 and the inner layer protection component 4, the energy exchange between the floating object and the riser 1 is greatly reduced, and it has a good anti-collision effect, and the protection layer 6 adopts a polym...

Embodiment 2

[0042] Such as figure 1 , 2 The shown riser protection device for an offshore platform includes a buoy 3 with a through hole 2, the riser 1 is located in the through hole 2 of the buoy 3, and the through hole 2 in the buoy 3 and the riser 1 are clearance fit, the The protective device also includes an inner protective component 4 , an outer protective component 5 and a protective layer 6 .

[0043] The inner protection assembly 4 includes a buffer ring 8 surrounding the periphery of the riser 1 and a fender 9 arranged between the riser 1 and the buffer ring 8, the buffer ring 8 is fixed on the upper surface of the buoy 3, and the fender 9 is along the There are 8 risers 1 in the axial direction, and the fenders 9 are evenly fixed on the inner wall of the buffer ring 8 .

[0044] The outer protection assembly 5 includes a protective sleeve 10 and a buffer structure 11 arranged between the buffer ring 8 and the protective sleeve 10. The protective sleeve 10 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com