Method for preventing tab reverse insertion to reduce battery cell failure

A technology of tabs and bare cells, which is applied in the field of preventing tabs from being inserted backwards and reducing cell failure, can solve problems such as reducing the space occupied by inactive substances, reducing the risk of taking up space and failure, preventing tabs from being misplaced, and ensuring safety. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

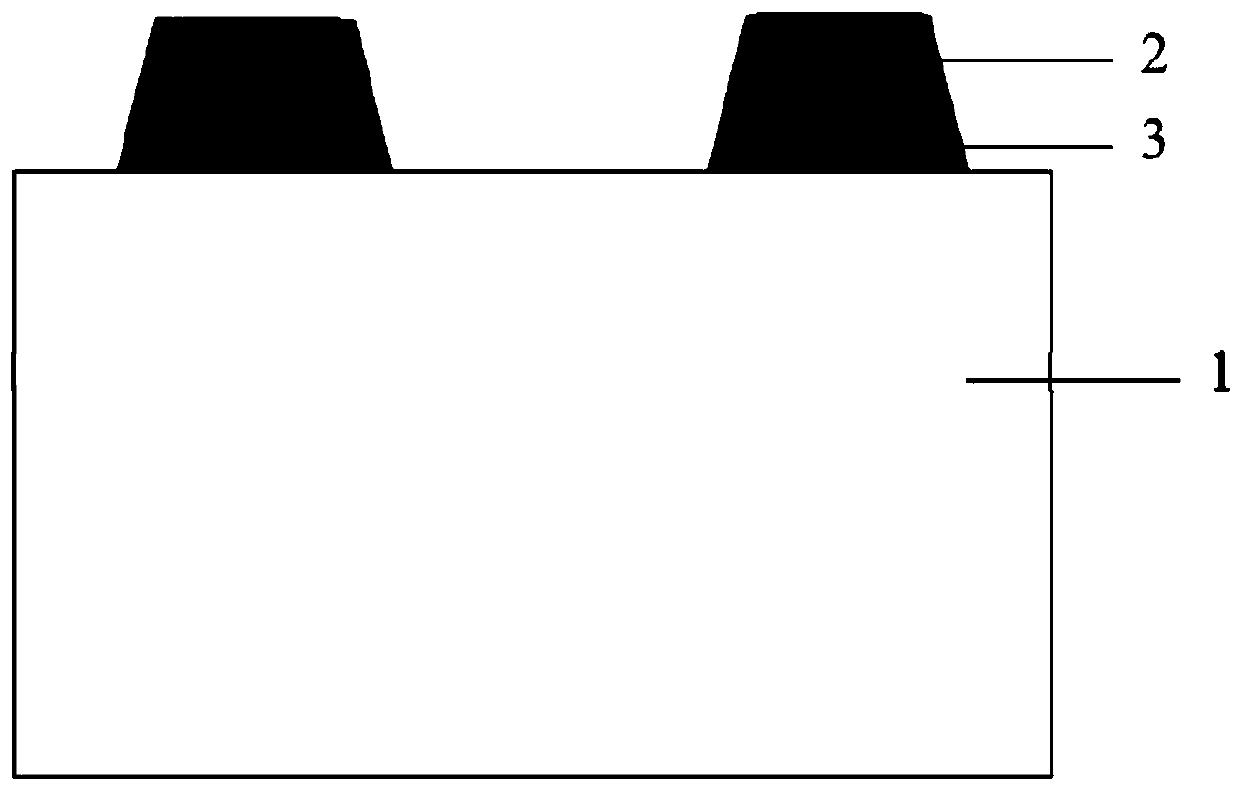

[0064] This embodiment provides a method for preventing tabs from being inserted upside down, and the method includes the following steps:

[0065] (1) The positive electrode sheet, the separator and the negative electrode sheet are stacked successively for winding, the width of the positive electrode sheet is smaller than that of the negative electrode sheet, the width of the negative electrode sheet is smaller than the separator, and two positive electrode sheets and the negative electrode sheet are respectively welded A trapezoidal tab, the trapezoidal tab has an upper bottom width of 10 mm, a lower bottom width of 30 mm, and a height of 25 mm;

[0066] (2) Perform laser welding at the root of the trapezoidal tab at a position at a vertical distance of 3 mm from the upper edge of the separator to integrate the tab to obtain a bare cell.

Embodiment 2

[0068] This embodiment provides a method for preventing tabs from being inserted upside down, and the method includes the following steps:

[0069] (1) The positive electrode sheet, the separator and the negative electrode sheet are stacked sequentially for winding, the width of the positive electrode sheet is smaller than that of the negative electrode sheet, the width of the negative electrode sheet is smaller than the separator, and 4 are respectively welded on the positive electrode sheet and the negative electrode sheet Trapezoidal lugs, the width of the upper bottom of the trapezoidal lug is 15mm, the width of the lower bottom is 35mm, and the height is 35mm;

[0070] (2) Perform laser welding at the root of the trapezoidal tab at a position vertically 9 mm from the upper edge of the isolation film to integrate the tab to obtain a bare cell.

Embodiment 3

[0072] This embodiment provides a method for preventing tabs from being inserted upside down, and the method includes the following steps:

[0073] (1) The positive electrode sheet, the separator and the negative electrode sheet are stacked successively for winding, the width of the positive electrode sheet is smaller than the negative electrode sheet, the width of the negative electrode sheet is smaller than the separator, and 6 are respectively welded on the positive electrode sheet and the negative electrode sheet A trapezoidal tab, the trapezoidal tab has an upper bottom width of 20 mm, a lower bottom width of 40 mm, and a height of 45 mm;

[0074] (2) Perform laser welding at the root of the trapezoidal tab at a position 15 mm perpendicular to the upper edge of the isolation film, integrate the tab, and obtain a bare cell.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com