A kind of preparation method of vanadium battery electrolyte based on vanadium compound

A vanadium compound and electrolyte technology, which is applied in fuel cells, aqueous electrolytes, acidic electrolytes, etc., can solve the problems of complex removal process, waste water pollution, high production cost, etc., and achieve simplified process flow, low energy consumption and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

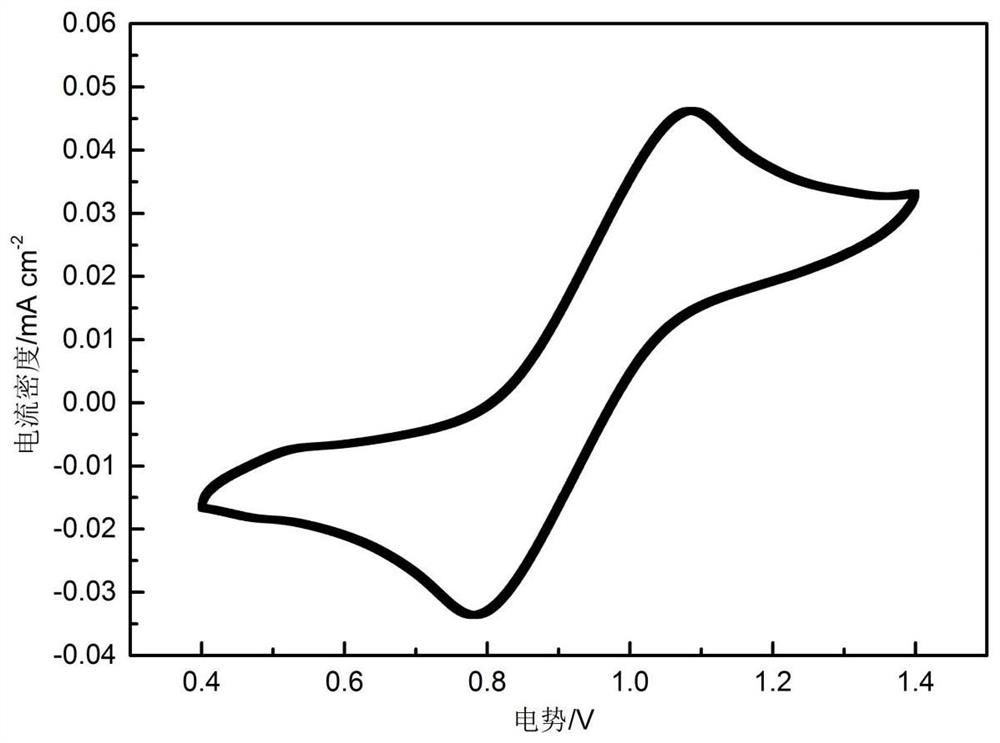

Image

Examples

Embodiment 1

[0046] A method for preparing a vanadium battery electrolyte based on a vanadium compound. The concrete steps of the method described in this embodiment are:

[0047] Step 1, according to supporting electrolyte: reducing agent: the molar ratio of vanadium compound is (2~4): (0.5~0.9): 1 batching, described supporting electrolyte, described reducing agent and described vanadium compound are mixed, obtain The mixture; according to the solid-liquid ratio of the vanadium compound and deionized water (200-750): 1g / L, add deionized water to the mixture, stir at 40-65°C for 0.5-3h, and separate the solid and liquid , Collect the liquid phase to obtain the electrolyte I.

[0048] The vanadium compound is at least one of vanadium pentoxide, vanadium dioxide and vanadium tetrachloride.

[0049] Step 2, according to carbon material: anion exchange resin: binder: the mass ratio of organic solvent is 1: (0.5~2): (0.05~0.25): (2~5) batching, described carbon material, described Anion exc...

Embodiment 2

[0057] A method for preparing a vanadium battery electrolyte based on a vanadium compound. The concrete steps of the method described in this embodiment are:

[0058] Step 1, according to the molar ratio of supporting electrolyte: oxidizing agent: vanadium compound is (3.5~5): (0.7~1.1): 1 batching, mixing described supporting electrolyte, described oxidizing agent and described vanadium compound, obtains mixture; According to the solid-liquid ratio of vanadium compound and deionized water (700~1000): 1g / L, add deionized water to the mixture, stir at 50~80°C for 2~4h, separate solid and liquid, collect Liquid phase, obtains electrolytic solution I;

[0059] The vanadium compound is at least one of vanadium trioxide, vanadium trichloride and vanadium dichloride.

[0060] Step 2, according to the mass ratio of carbon material: anion exchange resin: binder: organic solvent is 1: (2 ~ 4.5): (0.2 ~ 0.4): (4 ~ 8) ingredients, the carbon material, the Anion exchange resin, the bin...

Embodiment 3

[0068] A method for preparing a vanadium battery electrolyte based on a vanadium compound. The concrete steps of the method described in this embodiment are:

[0069] Step 1, according to supporting electrolyte: reducing agent: the molar ratio of vanadium compound is (5~7): (1~1.5): 1 batching, described supporting electrolyte, described reducing agent and described vanadium compound are mixed, obtain Mixture; according to the solid-liquid ratio of vanadium compound and deionized water (950~1200): 1g / L, add deionized water to the mixture, stir at 65~95°C for 3~6h, and separate the solid and liquid , to collect the liquid phase to obtain the electrolyte I;

[0070] The vanadium compound is at least one of vanadium pentoxide, vanadium dioxide and vanadium tetrachloride.

[0071] Step 2, according to the mass ratio of carbon material: anion exchange resin: binder: organic solvent is 1: (4~5): (0.4~0.5): (7~10) batching, the described carbon material, the described Anion exchan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com