Active control type air valve plate

A technology of active control and air valve, which is applied in the direction of motor vehicles, electric vehicles, climate sustainability, etc., can solve real-time adjustment, cannot realize pantograph and catenary, and cannot realize pantograph control unit real-time control of gas path Monitoring and other issues to achieve real-time monitoring and improve the quality of flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

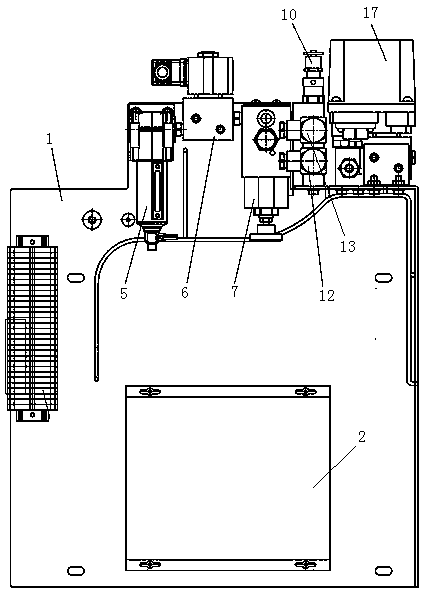

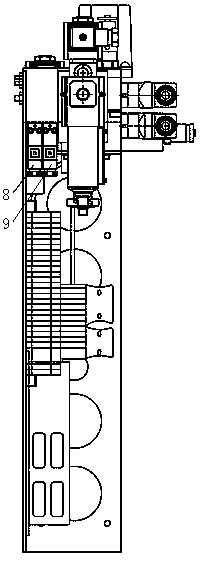

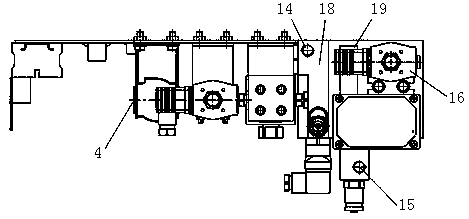

[0023] Referring to the accompanying drawings, this embodiment includes a bottom plate 1 on which a control unit 2 and an air circuit unit 3 are installed. The air circuit unit 3 includes an air inlet 4, a filter valve 5, a bow solenoid valve 6, a Precision pressure regulating valve 7, high frequency valve I8, high frequency valve II9, safety valve 10, pressure sensor I12, pressure sensor II13, air outlet 14, feedback port 15, electromagnetic quick discharge valve 16 and pressure switch 17;

[0024] The filter valve 5, bow-raising solenoid valve 6, pilot-operated precision pressure regulating valve 7, and electromagnetic quick discharge valve 16 are respectively fixed on the bottom plate 1 through brackets; the high-frequency valve I8, high-frequency valve II9, safety valve 10, The pressure sensor I12 and the pressure sensor II13 are fixed on the bottom plate 1 through the air circuit block I18; the pressure switch 17 is fixed on the bottom plate 1 through the air circuit block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com