Corrosion-inhibiting aluminum-clad strip and manufacturing method thereof

A technology for inhibiting corrosion and manufacturing method, applied in the field of strip and its manufacturing, can solve the problems of poor steel-aluminum bond strength, corrosion of steel-aluminum cross-section, affecting the use of aluminum-clad strip steel, etc., and achieves good corrosion resistance, excellent plasticity, good The effect of interface bonding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-15

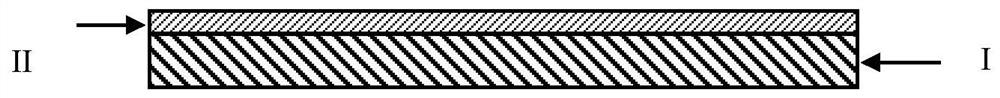

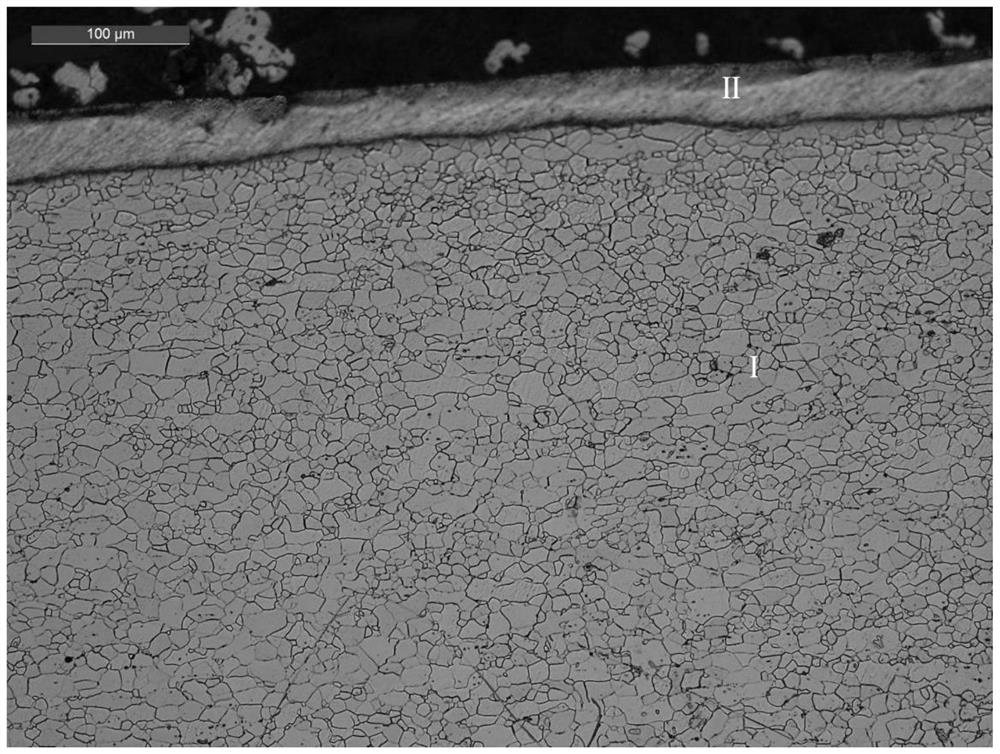

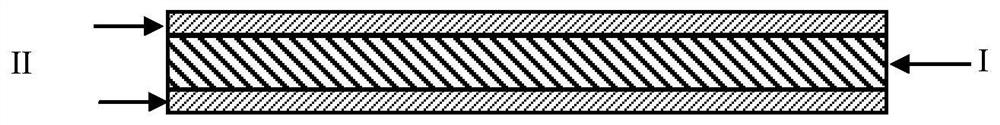

[0064] The aluminum-clad strips of Examples 1-15 include a steel substrate and an aluminum layer coated on the surface of the steel substrate, wherein the aluminum-clad strips of Examples 1-8 use a 0.2mm aluminum strip as the aluminum layer to be laminated on the steel substrate on one side. on (see the lamination method figure 1 ), the aluminum-clad sheet strip of embodiment 9-15 adopts the aluminum strip of 0.2mm to be laminated on the steel substrate as the double-sided aluminum layer (the cladding mode sees image 3 ), the mass percent of each chemical element of the steel substrate of each embodiment is shown in Table 1.

[0065] Table 1 lists the mass percentage (wt%) of each chemical element in the steel substrate of the aluminum-clad strip in Examples 1-15.

[0066] Table 1. (wt%, the balance is Fe and other unavoidable impurity elements except S)

[0067]

[0068]

[0069] The manufacturing method of the corrosion-inhibiting aluminum-clad strip of embodiment 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com