Electric spindle and machine tool

A technology of electric spindle and rotating shaft, which is applied in the field of machine tools, can solve the problems of machine tool table and machined parts pollution, lubricating oil leakage, electric spindle oil leakage, etc., and achieve the effect of reducing lubricating oil leakage, relatively smooth rotation, and keeping clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

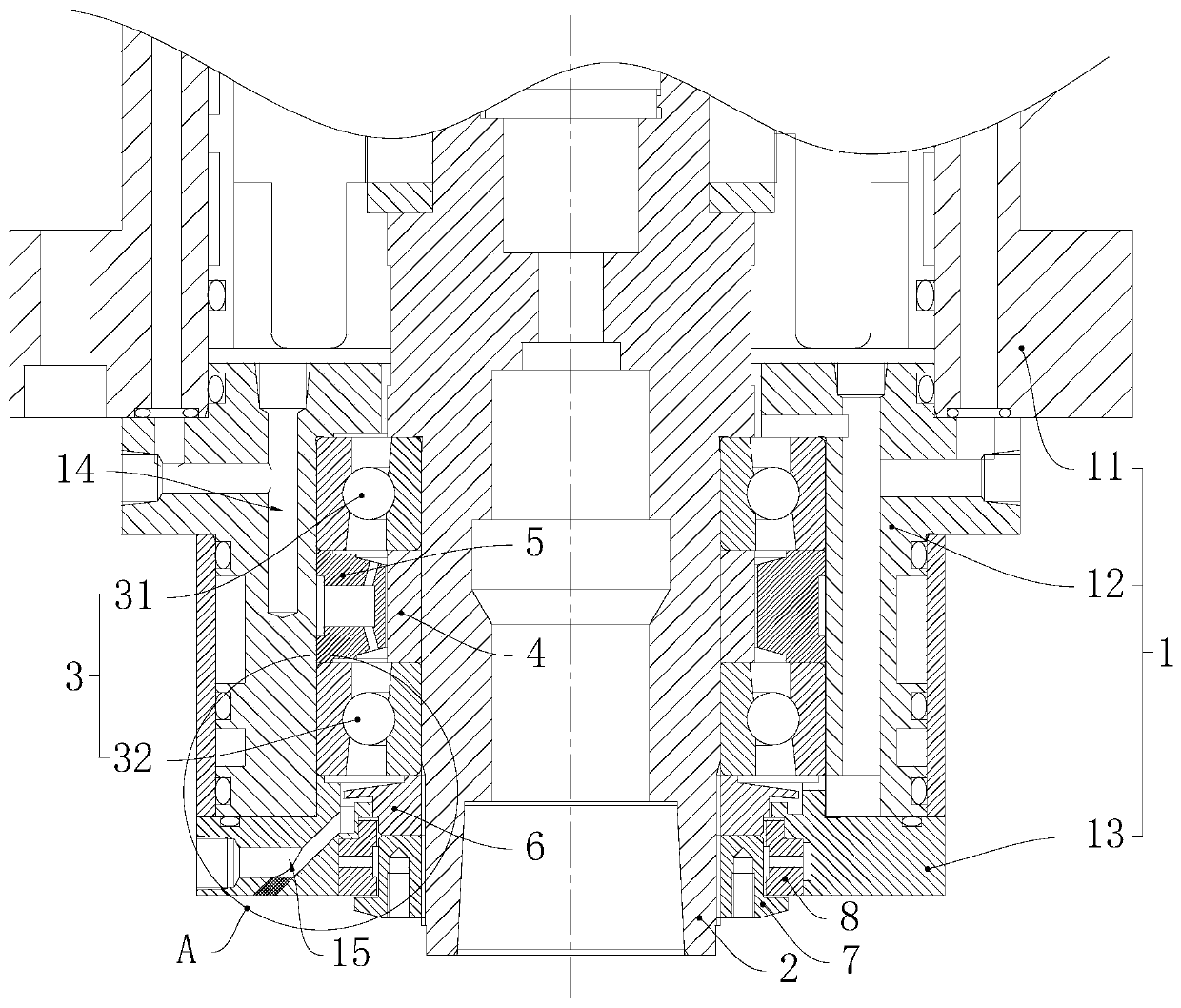

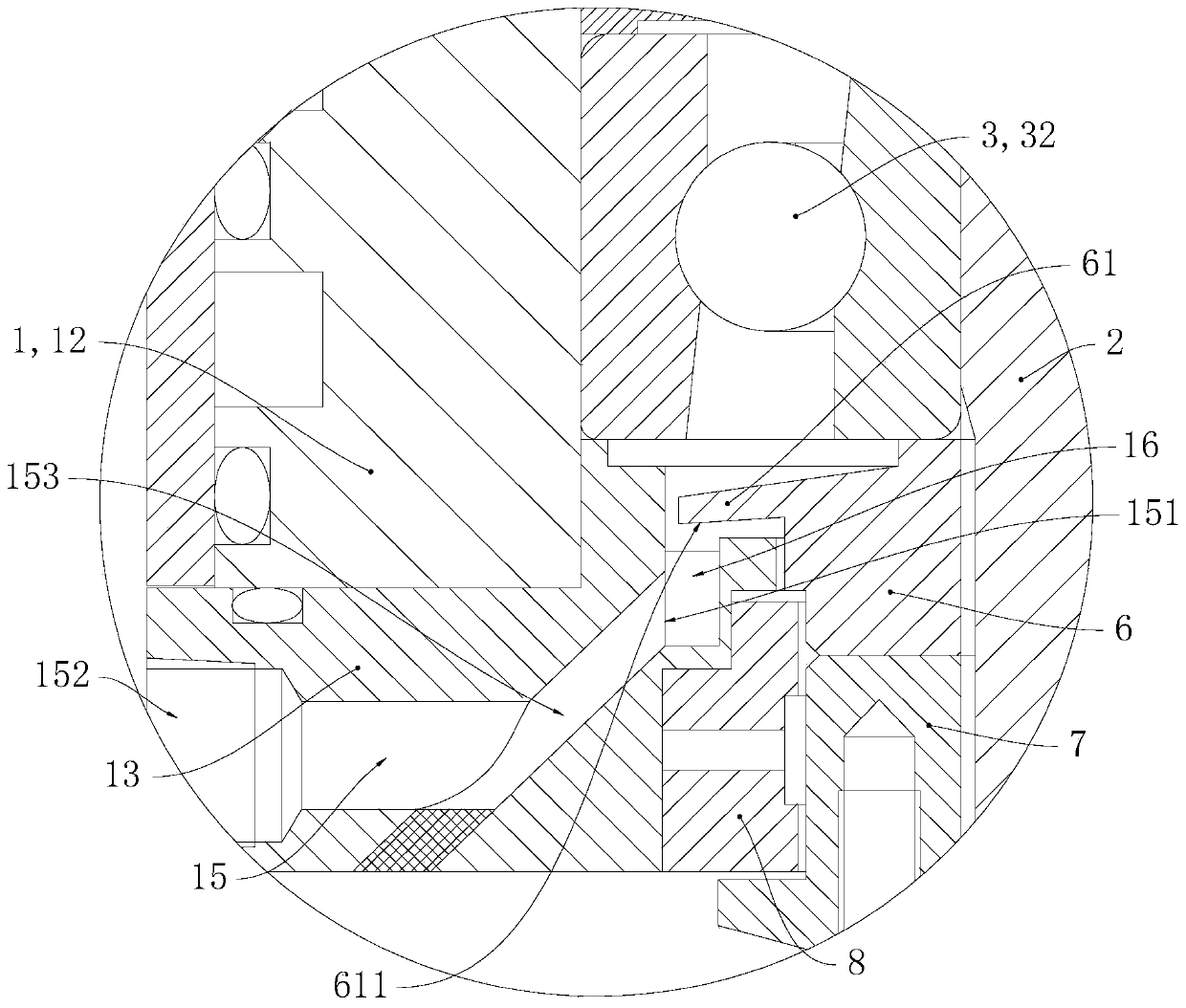

[0025] Please refer to figure 1 and figure 2 The electric spindle of this embodiment includes a base body 1, a rotating shaft 2, an end bearing 3, a seal ring 6, an air-tight structure 8 and a lock nut 7, and the base body 1 includes a cylinder body 11 fixedly connected, a bearing mounting seat 12 and a bearing press The cover 13, cylinder 11, bearing mounting seat 12 and bearing gland 13 are distributed vertically from top to bottom. Stretch down.

[0026] The end bearing 3 is installed between the bearing mounting seat 12 and the rotating shaft 2, the sealing ring 6 and the locking nut 7 are fixed on the rotating shaft 2, the rotating shaft 2 realizes the relative rotation with the base 1 through the end bearing 3, and the locking nut 7 It is threadedly connected with the rotating shaft 2.

[0027] A lubricating oil passage 14 is provided on the base body 1 , and the lubricating oil passage 14 is distributed on the cylinder body 11 and the bearing mounting seat 12 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com