Drying device utilizing biomass gas for heating

A technology of biomass gas and drying equipment, which is applied in the field of drying and can solve the problems of low resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention are described in detail below, and the embodiments described with reference to the drawings are exemplary, and embodiments of the present invention are described in detail below.

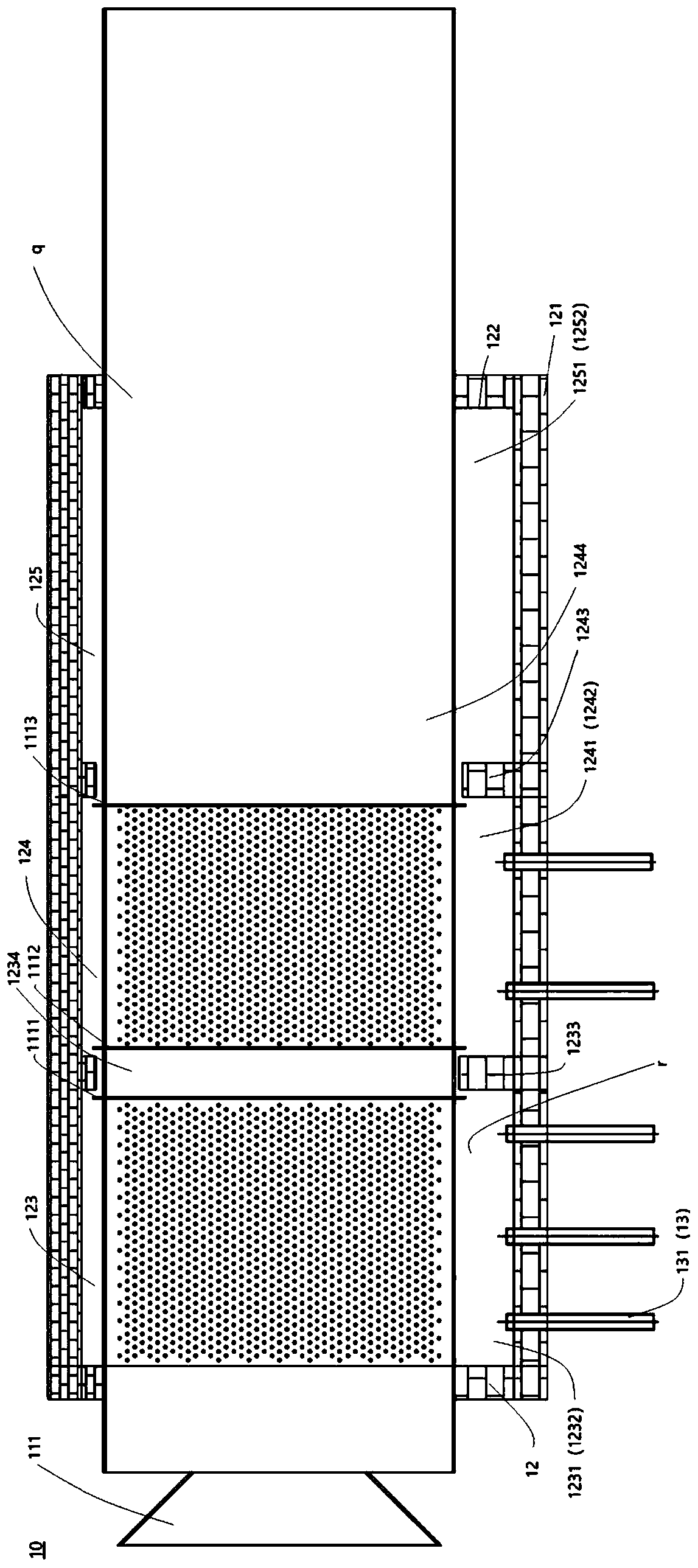

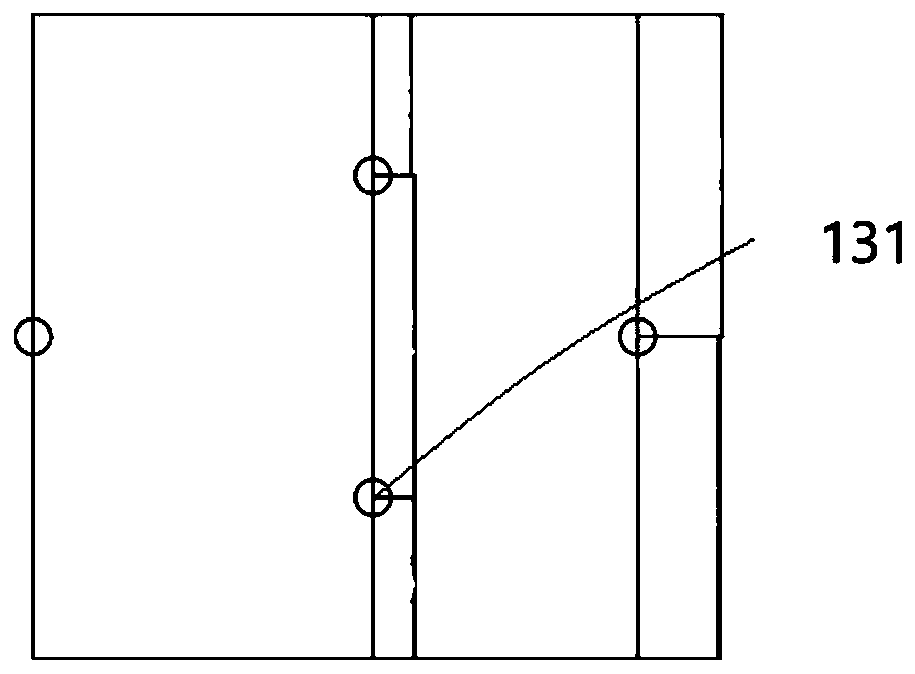

[0027] Refer below figure 1 Describe the drying device 10 heated by biomass gas according to the embodiment of the present invention, including: a rotary device 11, a casing 12 and a heating assembly 13, the casing 12 is arranged on the outside of the rotary device 11, and the heating assembly 13 is arranged on the casing 12, The heating assembly 13 is used for heating the rotary device 11 and the objects to be dried in the rotary device 11 .

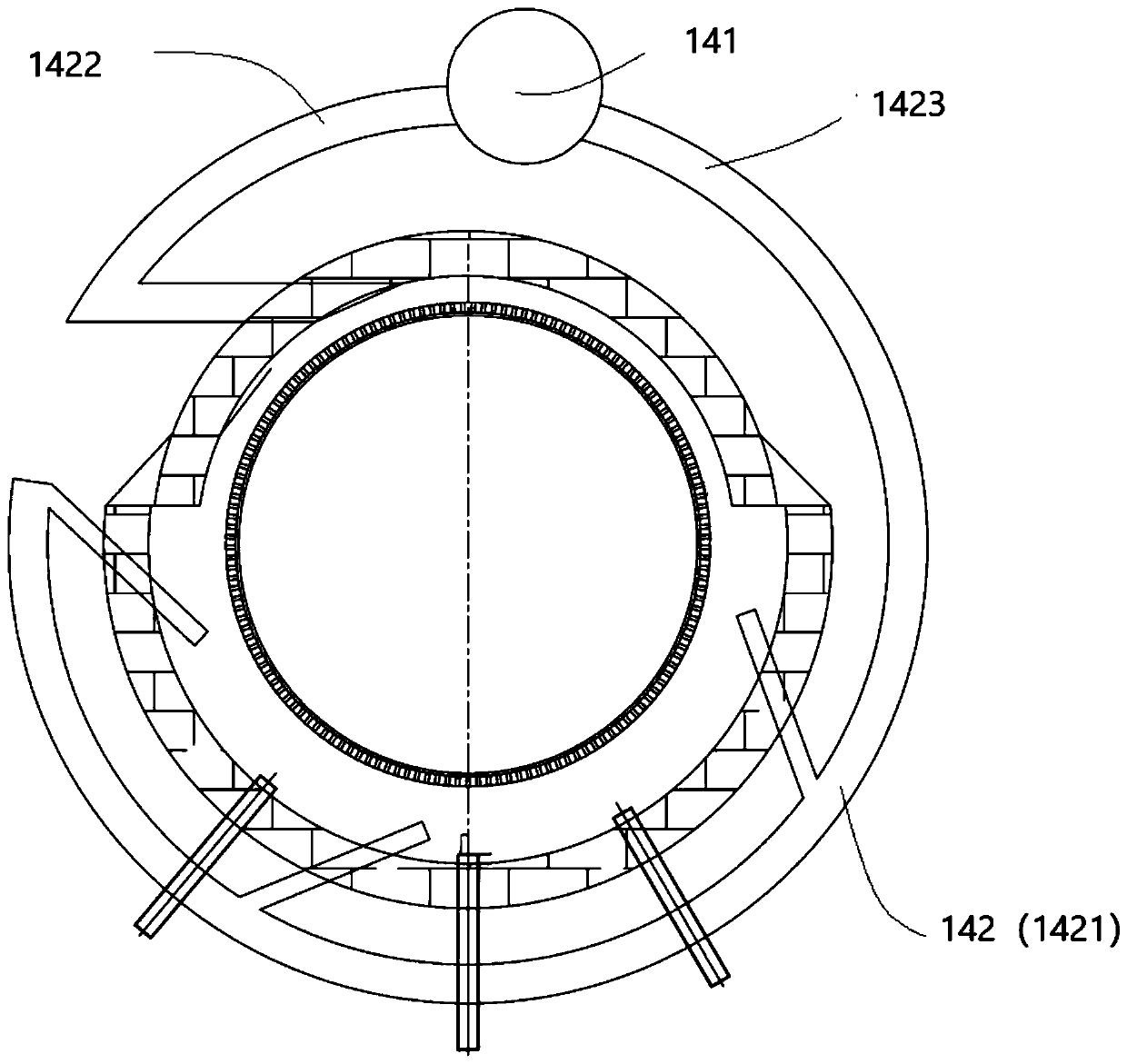

[0028] The rotary device 11 includes a rotary kiln 111. The rotary kiln 111 defines an accommodating space q for accommodating objects to be dried. The rotary kiln 111 is configured to be rotatable along the central axis. In the rotary kiln 111, a heating chamber is defined between the outer wall 121 of the rotary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com