Device for sealing plate layer of plate filter

A technology of filter plate and plate layer, which is applied in the direction of fixed filter elements, filter separation, chemical instruments and methods, etc., can solve the problems of short service life and high cost, and achieve long service life, low production cost, and easy wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

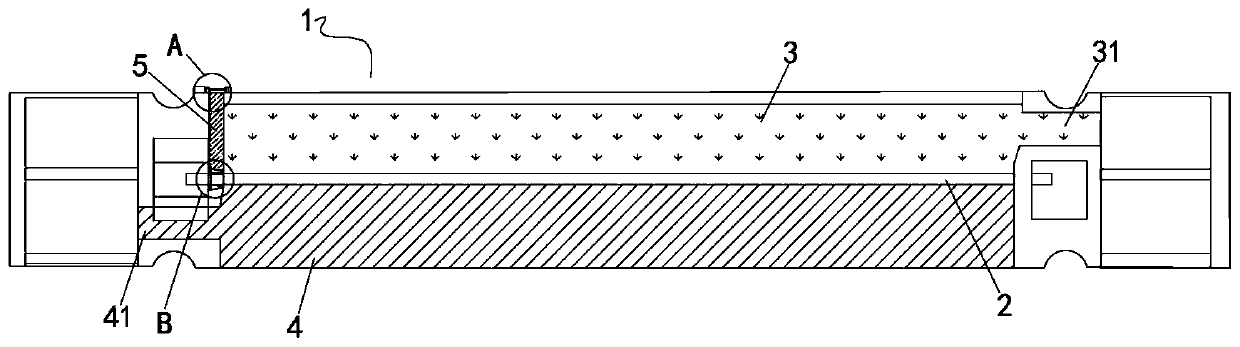

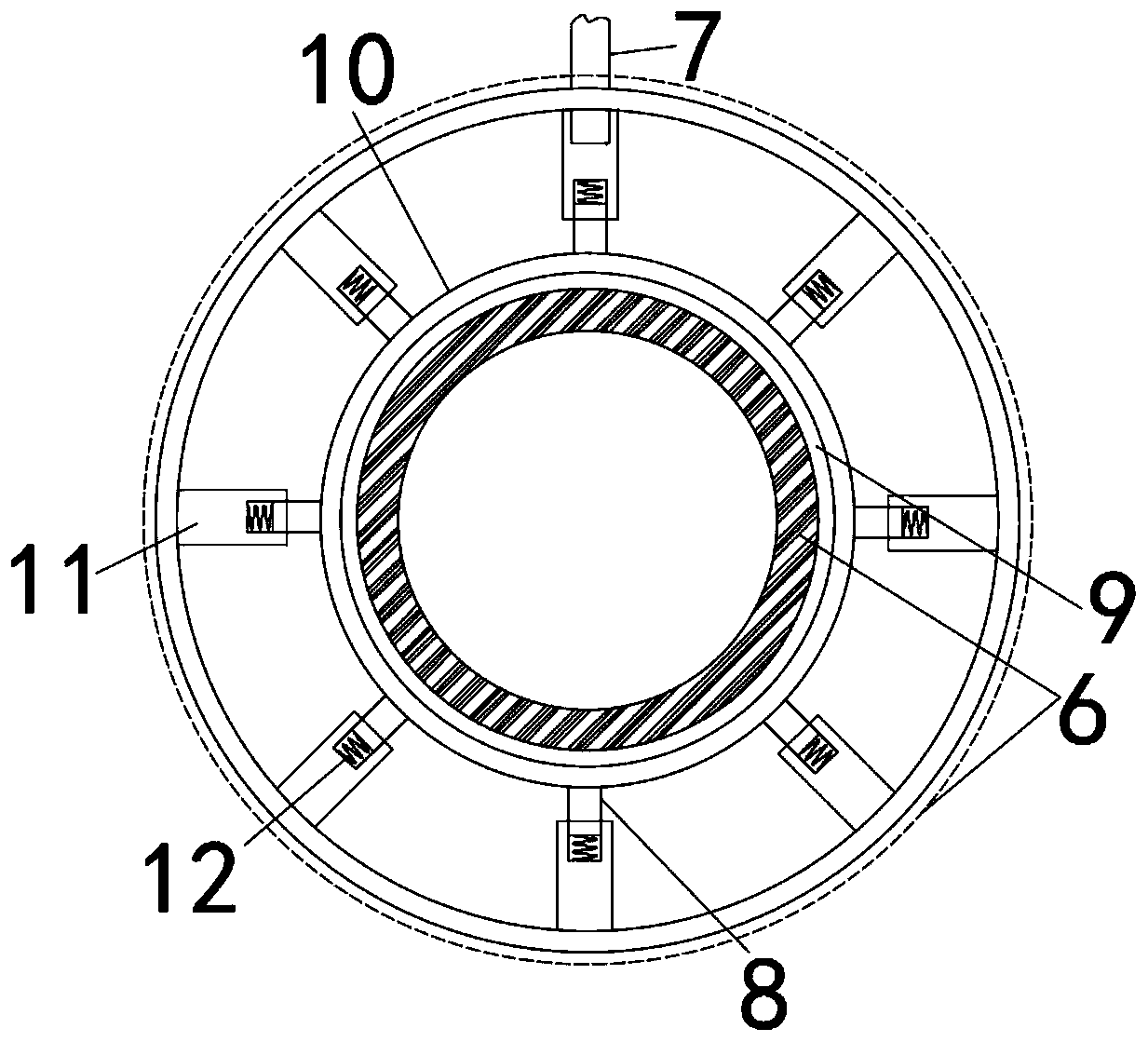

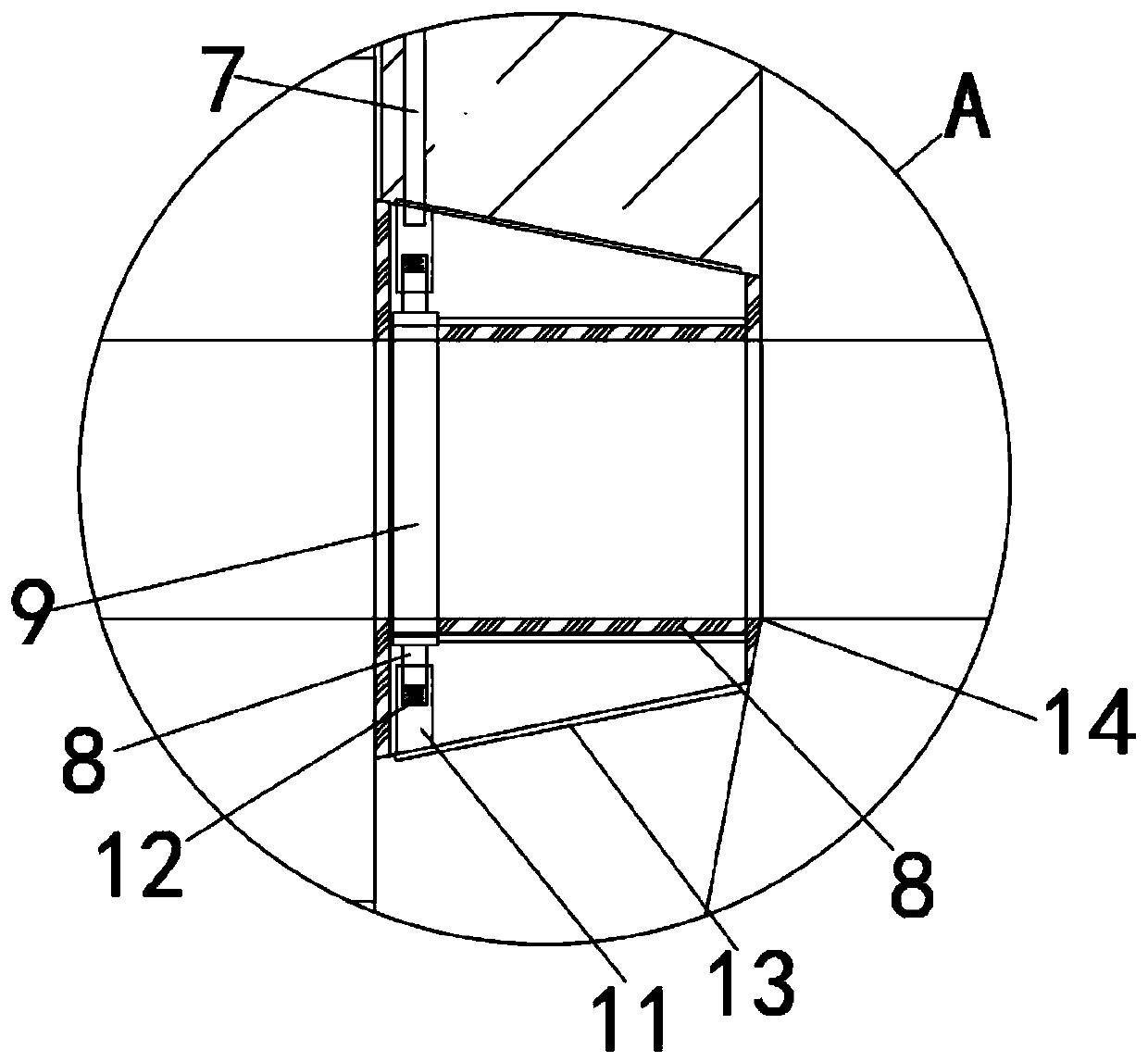

[0019] refer to Figure 1-4 , a device for sealing the plate of a plate filter, comprising a plate body 1, the plate body 1 is a cavity structure, the inside of the plate body 1 is provided with a filter paper 2, and the filter paper 2 wraps the plate body The inner cavity of 1 is divided into a dirty oil chamber 3 and a clean oil chamber 4. The interior of the plate body 1 is provided with a connected movable groove 5 and a negative pressure sealing groove 14 in sequence. The inner wall of the negative pressure sealing groove 14 is slidingly provided with an annular Distributed sliding seats 11, the top of one of the sliding seats 11 is fixed with a connecting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com