Layered magnesium-manganese composite material for copper ion adsorption, and preparation method and application thereof

A composite material, copper ion technology, applied in chemical instruments and methods, catalyst activation/preparation, adsorbed water/sewage treatment, etc., can solve the problem of small copper adsorption, achieve fast fixation, low price, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

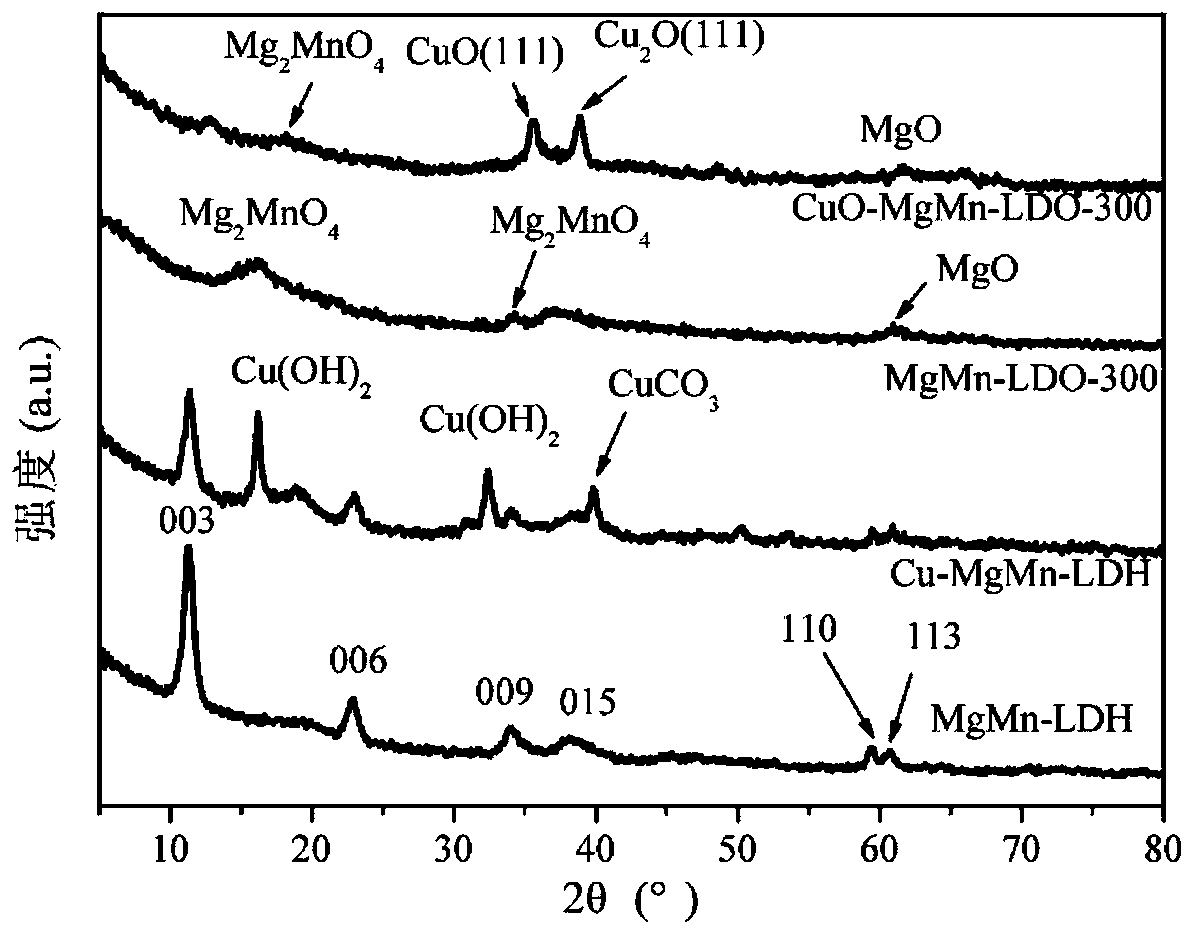

[0040] A preparation method of a layered magnesium-manganese composite material for treating copper pollution in wastewater according to this embodiment, the specific preparation steps are as follows:

[0041] (1) Accurately weigh 0.06mol magnesium chloride hexahydrate and 0.03mol manganese chloride tetrahydrate (Mg / Mn ratio is 2) and use 1000mL deionized water to dissolve to obtain magnesium salt and manganese salt composite solution;

[0042] (2) 0.005mol sodium carbonate and 0.01mol sodium hydroxide are dissolved in 1000mL deionized water to obtain carbonate and hydroxide composite solution;

[0043] (3) Slowly drop the composite solution of magnesium salt and manganese salt into the composite solution of step (2) at a rate of 2 mL / min, stir for 2 hours, and stir evenly;

[0044] (4) Aging for 24h, then removing the supernatant after centrifuging at 4000r / min for 5min, washing the precipitate several times with deionized water, freeze-drying for 24h, and grinding through a ...

Embodiment 2

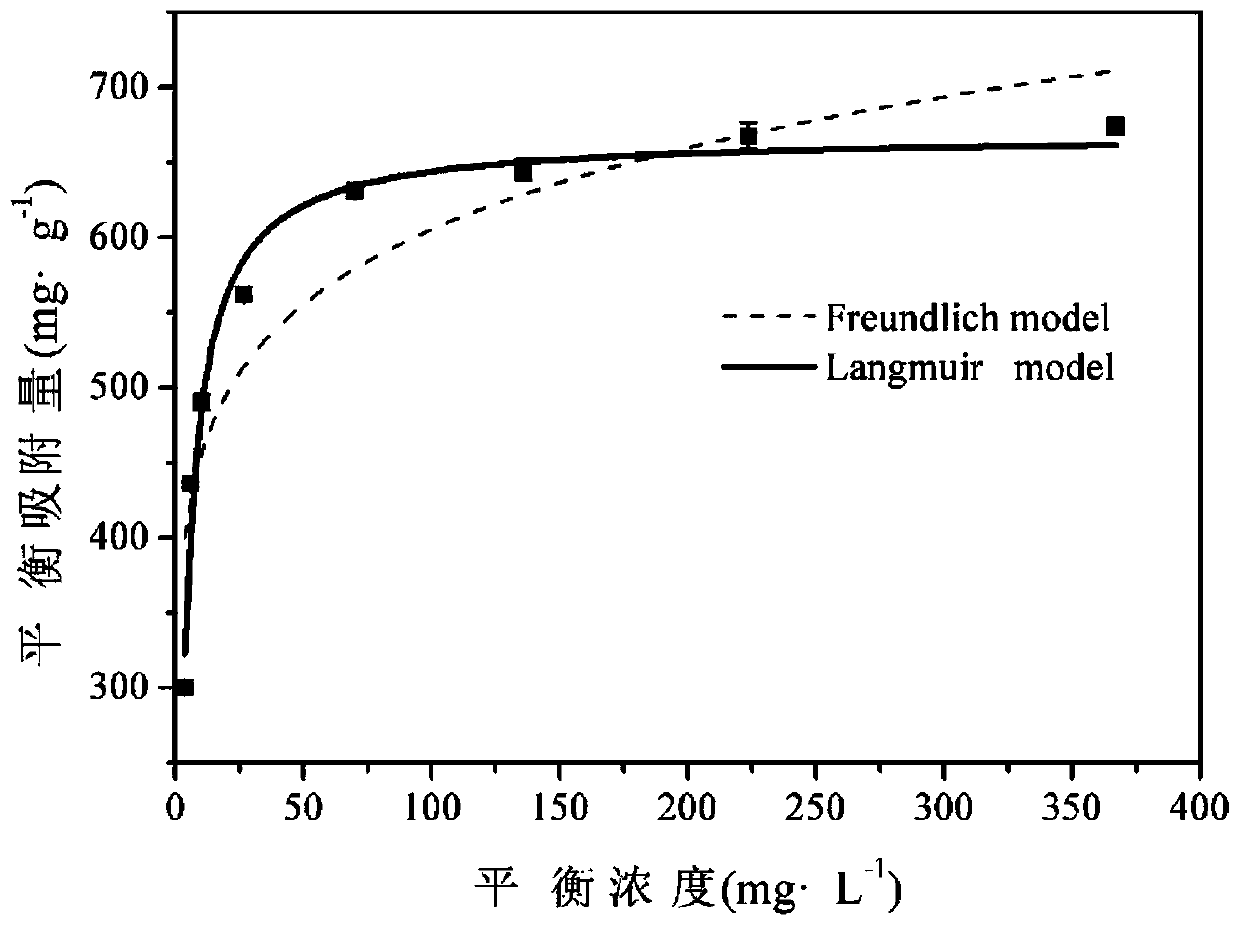

[0051] A kind of application of layered magnesium-manganese composite material in catalytic degradation of sulfamethoxazole comprises the following steps:

[0052] (1) Accurately weigh 0.06mol magnesium chloride hexahydrate and 0.03mol manganese chloride tetrahydrate (Mg / Mn ratio is 2) and use 1000mL deionized water to dissolve to obtain magnesium salt and manganese salt composite solution;

[0053] (2) 0.005mol sodium carbonate and 0.01mol sodium hydroxide are dissolved in 1000mL deionized water to obtain carbonate and hydroxide composite solution;

[0054] (3) Slowly drop the composite solution of magnesium salt and manganese salt into the composite solution of step (2) at a rate of 2 mL / min, stir for 2 hours, and stir evenly;

[0055] (4) Aging for 24h, then removing the supernatant after centrifuging at 4000r / min for 5min, washing the precipitate several times with deionized water, freeze-drying for 24h, and grinding through a 200-mesh sieve to obtain a layered magnesium-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com